Customer Story: 24/7 with 97% Uptime 5-Axis Milling and 5 µ Positioning

SPONSORED CONTENT

Pioneering paradigm shift at SCHUNK with automated 5-axis technology and mill-turn performance from DMG MORI.

SCHUNK GmbH & Co. KG has recently revolutionized the production of lathe clamping jaws with two new manufacturing systems from DMG MORI. Instead of the previous multi-stage production method, all process steps are now carried out on two ultramodern DMG MORI production units. A new 5-axis manufacturing system with specially developed clamping technology for machining 400 types of workpiece guarantees maximum flexibility. In a second project, Schunk has halved the throughput time for producing special clamping jaws in one pass with a milling-turning machine.

“The Pioneer has the courage to tread new paths,” is a saying by Heinz-Dieter Schunk, Managing Partner of SCHUNK, manufacturer of gripper systems and clamping technology with headquarters in Lauffen am Neckar. With 11,000 products, the company has the world’s largest gripper system and clamping technology range and the broadest spectrum of standard gripper components. This diversity of products promotes process flexibility.

It was in just this area that sequential manufacturing was threatening to reach its productive and economic limits. Milling at the soft machining stage alone was carried out in up to four steps. Long setup and downtimes were the result. Johannes Ketterer, Business Area Manager for clamping technology at the Lauffen factory, and his team therefore carried out a search for new production concepts.

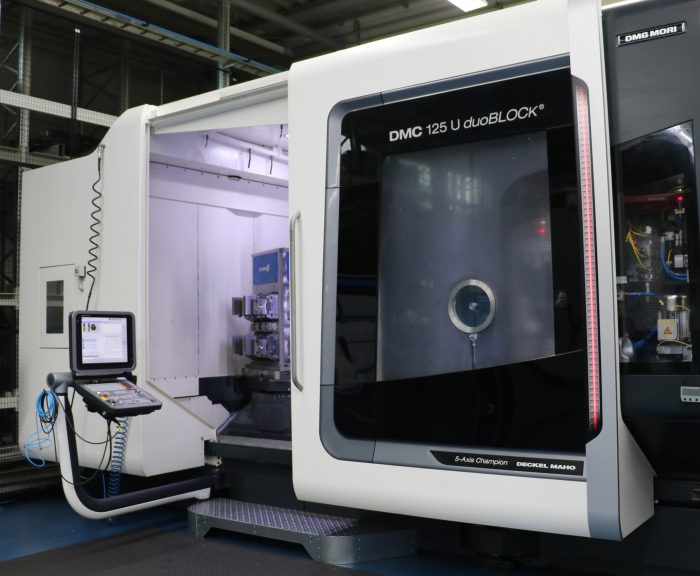

Johannes Ketterer, Business Area Manager (left in picture), together with production foreman Jochen Steinke by the DMC 125 U duoBLOCK.

DMC 125 U duoBLOCK – Automated production of 400 workpiece variants

One objective was to produce all 400 clamping jaw variants in batches of 20 to 80-off on just one machining center in large clamping turrets. A pallet storage system was to be connected in order to maximize machine running time. The DMG MORI DMC 125 U duoBLOCK five-axis machining centre with pallet changer proved to be the right machine for this task.

100% setup in parallel with production thanks to unique wheel magazine

The DMC 125 U duoBLOCK‘s large cubic work area enables the use of tools with dimensions of ø 49 × 63 inches and is therefore predestined for the use of high clamping turrets. On account of the heavy clamping devices, the machine pallets were of a special design and the maximum loading therefore increased from the standard 4409 lbs. to 5512 lbs. A wheel magazine with 243 pockets was employed due to the high diversity of workpieces and the use of sister tools.

On the one hand, the magazine is extremely space-saving. On the other, it enables setup to be carried out in parallel with production and during non-productive times. “Large chain magazines are almost exclusively to be found on the market at the expansion level we require. The compact and extremely fast DMG MORI wheel magazine is virtually unique in this area,” says Ketterer.

DMC 125 U duoBLOCK: The large cubic work area enables the use of clamping turrets with up to 36 clamping positions.

Ability to change 36 clamping positions in less than 15 minutes

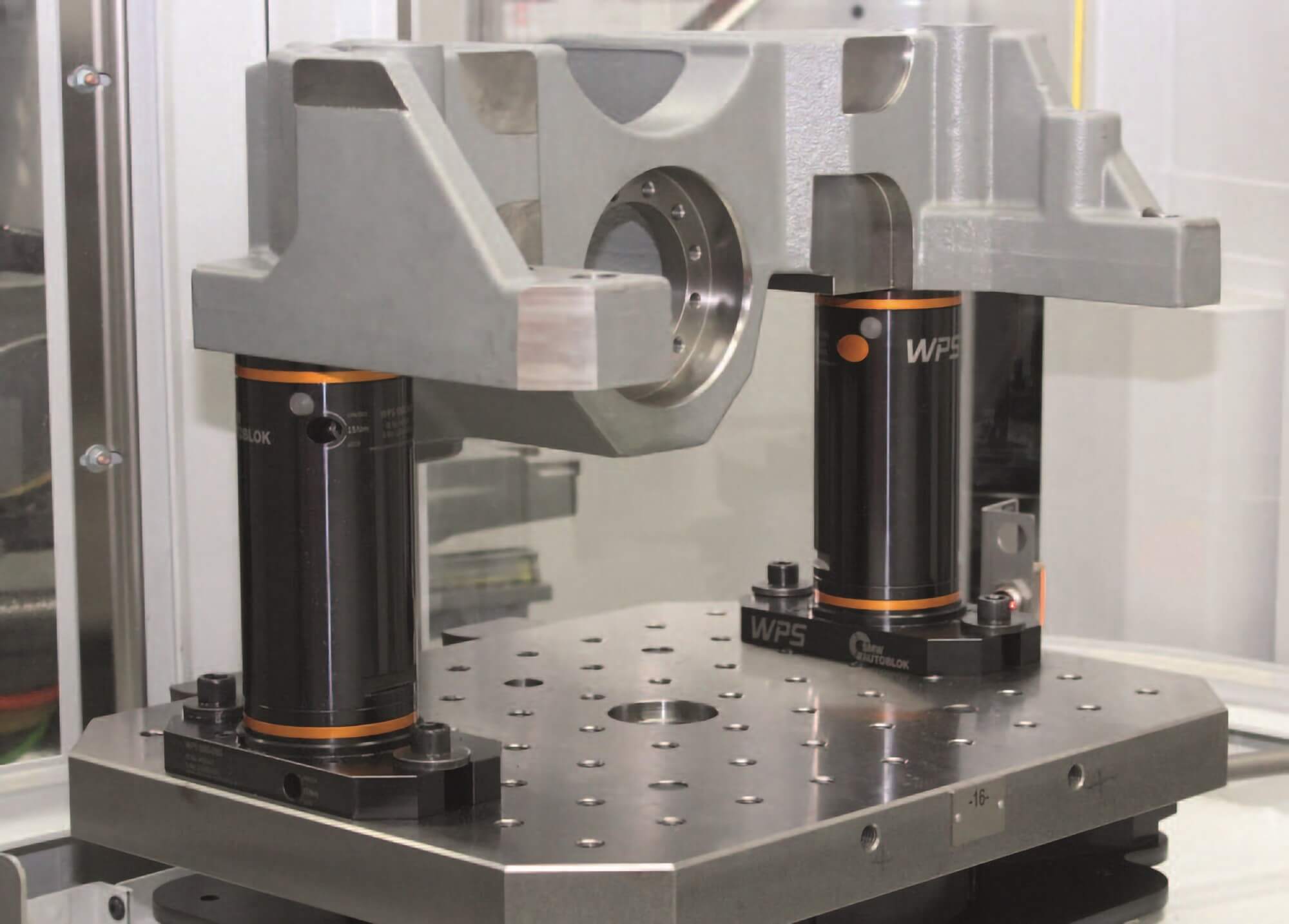

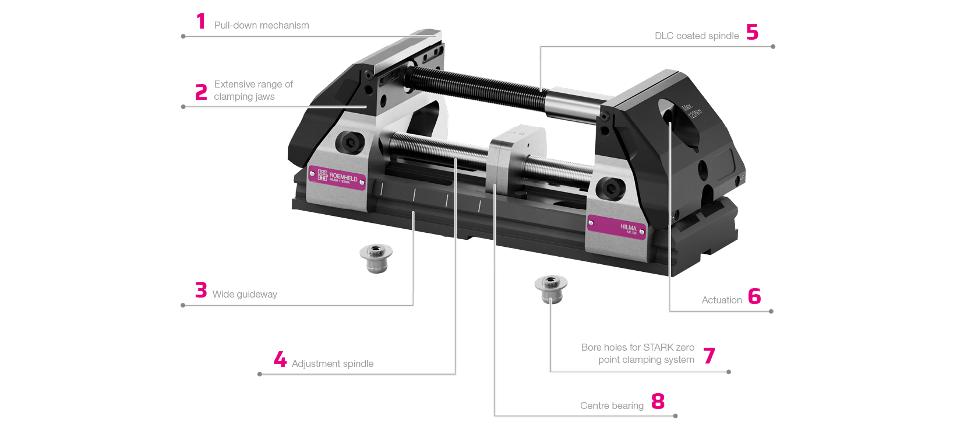

The pallet system with two set up stations provides space for a total of 16 machine pallets. Manufacturing takes place on large horizontal clamping turrets, each with up to 36 clamping positions fitted with SCHUNK TANDEM power clamping blocks.

Quick-change inserts, which manage entirely without the use of screws and which can be fitted and replaced using ball locking bolts or magnets, are fitted on these power clamping blocks. The result is that a clamping turret with up to 36 clamping positions can be changed from one component to another in less than 15 minutes.

< 5 µm positioning accuracy in X, Y and Z

The machining process is also designed for maximum running time. Scanning of the zero points, which requires the highest precision of machine and clamping devices, is dispensed with. The DMC 125 U duoBLOCK with increased accuracy has a fully cooled feed drive, coolant temperature control and Thermoshield for preventing draughts. The machine is therefore almost completely decoupled from the ambient conditions. The result is a positioning accuracy of < 5 µm in X / Y / Z.

97% machine utilization in 24-hour operation

Setup and loading and unloading of the pallets in the turret magazine are carried out in parallel with production. “On good days, a utilization level of 97% is achieved during a 24-hour period of machine running – even with an extreme diversity of variants,” emphasises Johannes Ketterer.

DMG MORI technology cycles aid operators with setting up and adjusting the MPC parameters (Machine Protection Control) for maximum security during the automated process.

DMC 80 FD duoBLOCK – More than 50% shorter throughput time thanks to complete machining

As well as the 1,200 standard clamping jaws, there are also numerous customer-specific special designs, of which about 25% require a turning operation. Previously, this was carried out on a lathe following the various milling operations. In order to be able to respond to customer requirements more quickly and more flexibly in the future, the decision was made for the first milling-turning machine in the SCHUNK factory with the DMC 80 FD duoBLOCK from DMG MORI.

Special clamping jaws in batches from 3 to 12-off are fully machined on the milling-turning 5-axis machining centre. The SCHUNK VERO-S zero-point clamping system was adapted for use on a milling-turning machine and fitted to the milling/turning table. Johannes Ketterer is delighted with the rigidity of the duoBLOCK concept: “The rigidity of the machine even allows turning to be carried out with intermittent cutting. In the meantime, turning and milling is increasingly carried out in the hard state, which saves whole process steps and therefore downtime.” A digital process chain has been implemented in order to also optimize the setup time. The manufacturing programs are produced and simulated and the clamping situation defined in production engineering. “Overall, this has enabled the throughput time to be more than halved,” estimates Johannes Ketterer.

Manufacturing in grinding quality thanks to duoBLOCK concept and SCHUNK clamping devices

SCHUNK is thoroughly satisfied with the results. In both cases, the number of setups has been reduced, which is reflected in higher accuracy as well as shorter throughput times. Thanks to the perfect synergy between DMG MORI machine and SCHUNK clamping devices, in some cases entire process steps can be dispensed with.

Highlights:

- DMC 125 U duoBLOCK with increased accuracy: 5 µm positioning accuracy in all linear axes

- Up to 97% utilization in 24/7-operation thanks to automated 5-axis machining

- Rack storage with two setup stations for 16 pallets up to 5512 lbs.

- Complete wheel magazine with 243 pockets

- DMC 80 FD duoBLOCK: 50% shorter throughput time with special clamping jaws thanks to mil-turn technology

- High stability for high-performance turning with intermittent cutting

- Precision and surface quality eliminate the grinding process

SCHUNK Facts:

- Established as a mechanical workshop in 1945

- Almost 3,000 employees in nine factories and 33 national affiliates

as well as sales partners in more than 50 countries - Globally unique: 11,000 standard components for gripper systems and clamping technology