A View of the Skies Ahead

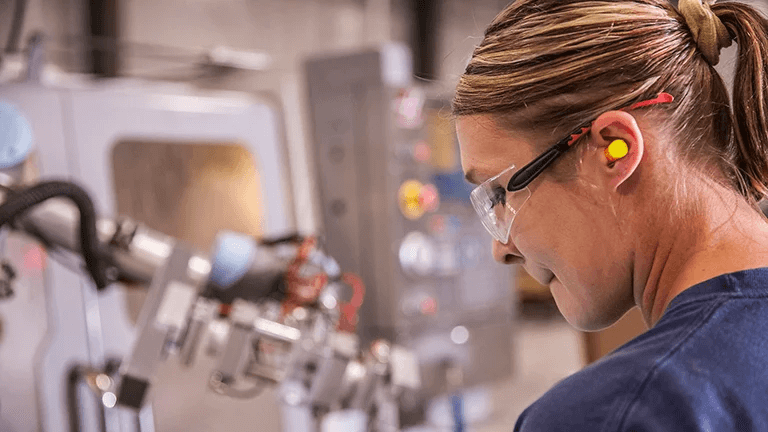

Machining solutions paving the way for tomorrow’s aerospace manufacturing.

Out of all areas of modern industry, it’s fair to say that the aerospace sector has undergone one of the most significant transformations of the past decade. First, we cannot mention aviation disruption without citing the COVID-19 pandemic. Airlines suffered $168 billion in economic losses in 2020 as the pandemic grounded aircraft, wiped billions from industry revenues and cost around 200 million jobs.

Next, we must consider sustainability. It is widely considered that between two and three percent of global CO2 emissions come from aviation. If we factor in vapor trails and gases emitted during flight, then that figure rises to around five percent. Aviation business leaders are therefore under pressure to take huge leaps in climate action to ensure that the future of flight can be more sustainable, with every fixture, fitting and component being made lighter to reduce fuel consumption.

Finally, aerospace is one of many sectors experiencing the impact of digitalization. However, while it’s difficult to pinpoint an industry that isn’t undergoing change because of digital technologies, aviation faces some unique challenges that it must work to conquer while carefully balancing the increased use of data with the stringent regulations that surround every area of production and manufacturing.

The aerospace industry had been growing consistently for 14 years when the pandemic struck, and there is no doubt that trends in aerospace were affected immensely. There was exponentially reduced business and vacation travel, by as much as 97 percent in the peak of the pandemic, while airlines had to adjust to substantially lower levels of profitability.

Over the long term, by 2040, it is likely that the number of new airplanes will still have decreased by 25 percent. But, going forward, it isn’t all bad news. While the speed of recovery will vary in different countries and regions, projections estimate that the industry will be back to where it was pre-pandemic within the next two to three years.

Aerospace OEMs need the right manufacturing tools and techniques to make the industry stronger, greener and better prepared for the future.

But where there’s challenge, there is also opportunity. The aerospace sector is recovering from the perils of the pandemic while continuing its path toward increased sustainability and digitalization. Aerospace original equipment manufacturers (OEMs) must seize these opportunities, and, to do so, they need the right manufacturing tools and techniques to make the industry stronger, greener and better prepared for the future.

What do these trends mean from a design engineering perspective?

More passenger aircraft are being designed with a single aisle rather than twin aisles, so they are less wide-bodied. These single-aisled craft will be required to satisfy a wider range of commercial uses, without increasing the size or quantity of the engine. Tomorrow’s aircraft also will be required to exhibit longer flying ranges with engines that are lighter and more efficient but with reduced noise, less fuel consumption and fewer emissions.

There are different ways of approaching these engineering challenges. One is to investigate — using existing engine tanks — the use of alternative fuels such as synthetic fuel, biofuel or hydrogen. Then you have new engine architecture, with large manufacturers presenting new types of engines, which is a longer-term approach.

As with automobiles, tomorrow’s aircraft will increasingly rely on electrified, battery-driven or hybrid engines. Indeed, the automotive industry is already making great progress with new electrified and hybrid systems. Aerospace OEMs, meanwhile, are still working on these systems, and many of these developments are not expected to find widespread use before 2035. easyJet hopes to run electric planes on routes under 311 miles (500 km) by 2030, and Norway is aiming to make all short-haul flights electric by 2040. Yet, despite these advancements, Lonely Planet predicts that “we won’t be flying long-haul on rechargeable jumbos any time soon: the batteries are simply too heavy.”

Batteries need to become lighter to become plausible — but how? Aerospace OEMs are increasingly turning to lighter materials, like aluminum and heat-resistant super alloys (HRSAs), to manufacture lighter components.

Aside from the engine, design engineers are also exploring new aircraft body shapes, like delta shape, blended wing body and strut-braced wing, or where the engine is more integrated into the fuselage. Here, engineers will more likely turn to composite, or composite-ceramic combinations, and mixed materials.

Whether these designs become popular remains to be seen. For now, we can be sure that more aluminum and HRSAs will be used. HRSAs are typically used for aircraft parts that face extreme performance demands. Their high strength at elevated temperatures means the materials retain their hardness, even when facing intense heat.

A deeper dive into HRSAs

A limiting factor with aero engines is that the core of the engine is relatively small, and the fan on the front is relatively large — so, the limit is with how fast you can rotate the fan. Over the last five to 10 years, gearboxes have been introduced between the fan and the core of the engine that enable the fan to run more slowly while the engine runs faster. The end result is better fuel efficiency.

Aerospace OEMs are increasingly turning to materials like HRSAs to manufacture aircraft parts that face extreme performance demands due to their high strength at elevated temperatures.

However, HRSA components are needed to make this work. Such materials are metallurgically composed to have high strength at temperatures of up to 1,000 degrees Celsius. But this also means that the stresses generated when machining these materials are high. The unique capability of these nickel-, iron- and cobalt-based super alloys to perform close to the melting point of their basic metal gives them generally poor machinability.

However, tool providers are offering tooling solutions to help. Sandvik Coromant offers a number of tooling solutions to support cost-effective, high-quality machining of HRSA aero engine components. One such method is high-feed side milling. This technique involves a small radial engagement with the workpiece, which allows increased cutting speeds and feed rates and axial cutting depths with decreased heat, chip thickness and radial forces.

To support this method, Sandvik Coromant developed the CoroMill® Plura high-feed side milling (HFS) range. The range features a series of end mills with unique geometries and grades and is made up of two optimized versions, one for HRSA materials and one for titanium. Chip evacuation and heat are specific challenges when machining titanium, so the first version presents a solid version of the tool for normal chip evacuation conditions. The second version features internal coolant and a new cooling booster for optimum swarf and temperature control.

A customer trial was performed to test a 12 mm diameter CoroMill Plura HFS end mill against a same-sized competing tool. This trial involved machining a low-pressure turbine (LPT) case made from aged Waspaloy 420 nickel-based alloy using a horizontal machining center with an increased axial depth-of-cut and reduced radial depth-of-cut. The outcome was that metal removal rates were increased substantially with CoroMill Plura, leading to an impressive 198 percent productivity increase for the customer. The solution has also been applied to blisks, as well as turbine disks and casings, machining blades and weight-reduction scallops.

Specially designed turning inserts can also help when machining HRSAs. For example, Sandvik Coromant’s S205 turning grade can be run at faster cutting speeds while maintaining superior surface quality, without having detrimental effects on the component’s material integrity. So too can milling cutters. Sandvik Coromant’s CoroMill MH20 is a high-feed milling cutter designed primarily for milling cavities, or pockets, in ISO S, M and P materials. The tool’s innovative insert cutting edge geometry delivers a gradual and light-cutting action to help support vibration-free production in aerospace component manufacturing.

Other challenging materials

Sialon and whisker ceramics are viable alternatives for both turning and milling of HRSAs. One important subgroup is Inconel alloys, typically used for high-temperature applications, including within aircraft engines or energy production processes. Ceramics are strong and have low reactivity with workpiece materials, but a downside is they exhibit low toughness compared with cemented carbides. This requires a rigid machining process with minimal vibrations. Tool overhangs should be short, entries and exits should be smooth and, in milling, full slotting should be avoided.

The principal guideline for ceramic milling is to use relatively low feed rates, of around 0.05 to 0.08 mm/tooth to achieve high cutting speeds. The resulting high temperature around the cutting zone enhances the cutting action and facilitates efficient removal of small, red-hot chips. Face milling is preferred over edging and waterline milling.

At 30 percent stronger and 50 percent lighter than steel, titanium is an increasingly attractive material for aerospace parts. However, machining titanium presents its own challenges. Titanium alloys can have twice the hardness of stainless steel, and so, when paired with titanium’s low thermal conductivity, high thermal and mechanical loads are placed onto the tools tasked with cutting the metal.

Aluminum is soft and ductile, and it can adhere to tools, leading to a build-up edge on the insert. Cutting tools for aluminum should generally be very sharp, possibly even polished, utilize specialist coatings and work at very high surface speeds to prevent the aluminum from adhering. High-strength aluminum used in aerospace, such as aluminum lithium, can be abrasive and requires sharp edges and high surface speeds. Dynamic stability is also an important consideration to prevent imbalances and vibrations while machining.

Tool recommendations for aerospace components

Before we delve further into the challenges and opportunities in aerospace manufacturing, let’s look at the tools OEMs need to succeed.

Turbine discs: Rotation prevention and insert indexing have long been recurring challenges when machining with round inserts. To solve this issue, Sandvik Coromant developed the CoroTurn® 107 concept with rail interface. The interface locks the rotation of the insert, delivering higher performance and process security. Edge indexing also becomes simpler, which enables standardized processes and indexing repeatability.

The S205 turning grade was designed to complement the CoroTurn 107 and is designed for light roughing to finishing of HRSA materials. The grade’s second-generation Inveio® coating technology enables an increase of cutting speeds by 30 to 50 percent when compared to competing grades, stretching the limits of cutting speeds for coated inserts. Grade S205 delivers an exceptional performance when applied with an entry angle up to 45 degrees.

Grooving is another essential methodology for turbine disc machining, and the CoroCut® 2 concept holds a large selection of carbide, CBN and ceramic insert grades.

Blisks: Blisks are often made from HRSA materials, and high-feed side milling is an effective machining method. CoroMill Plura high-feed side milling end mills with grade GC1710 are specifically developed for nickel-based HRSA materials. Its core dimension optimized for high stiffness makes CoroMill Plura the first choice for reliable and productive milling of blisks.

A plunge milling strategy can make manufacturing of deep cavities more time- and cost-efficient, and CoroMill Plura Gannet is designed exclusively to meet the demands of plunge milling in HRSAs.

CoroMill 331 and CoroMill QD indexable groove milling cutters are powerful alternatives to effectively remove large volumes of material between blisk blades in a fast and cost-efficient way. Combined with Silent Tools™ damped milling adaptors, the concepts provide vibration-free grooving operations when machining with long overhangs and when blisk and machine configuration allow access with reasonable assembly length.

Spools: Deep internal chambers and external blade dovetail grooves are two demanding features encountered when machining the spool. T-Max® P is a trusted concept with a wide assortment of V-bottom and double-sided flat inserts with strong edges for reliable and secure spool machining, particularly during inner pocket operations.

Casings: A combustion casing contains boss features of different shapes and sizes. CoroMill Plura end mills are ideal for every step of the machining process, from removing material between the features and roughing, to delivering the required form and surface finish to the blend. Multi-axis side milling with the CoroMill Plura ball nose end mill is a suitable method for roughing the blend with the best result.

Shafts: The small entry angle facilitated by PrimeTurning™ is very well suited for machining HRSA and titanium alloys for shafts. The generated chip-thinning effect allows an increase of feed per revolution with up to three times. Another benefit of small entry angles specific to HRSA machining is the decreased risk of notch wear, while the possibility to use a one-pass strategy avoids unwanted seams in the surface.

Are we ready for additive manufacturing?

Another path to producing lighter and more fuel-efficient aircraft is through additive manufacturing (AM) techniques. AM allows the development of very complex-shaped customized parts and functional products to tight tolerances, so difficult-to-machine parts like lattices can be machined more easily. According to findings by software company Dassault Systemes, “weight reduction from AM processes can result in energy savings of up to 25 percent,” while “each kilogram of weight loss on a flight can save up to $3,000 in fuel annually.”

But is AM manufacturing itself sustainable? A study, co-authored by the Department of Manufacturing Engineering at Romania’s Technical University of Cluj-Napoca, describes AM as “a great alternative to traditional manufacturing methods like injection molding, die-casting or machining … AM has the potential to lower costs and to be more energy-efficient than conventional processes.”

AM will also have a crucial effect on the manner and diversity of how products are manufactured. Advantages can include reduced carbon emissions, less material usage and less transportation because parts can instead be made in-house instead of imported.

Manufacturers can also produce more complex, compact and innovative aerospace parts through rapid prototyping. Rapid prototyping refers to several techniques, but the goal is to quickly produce a tangible 3D prototype from a computer-aided design (CAD) file. With these prototypes, small volume trials of new materials can be performed before full-scale manufacturing to ensure components are made with the utmost innovation, quality and precision.

Aerospace goes digital

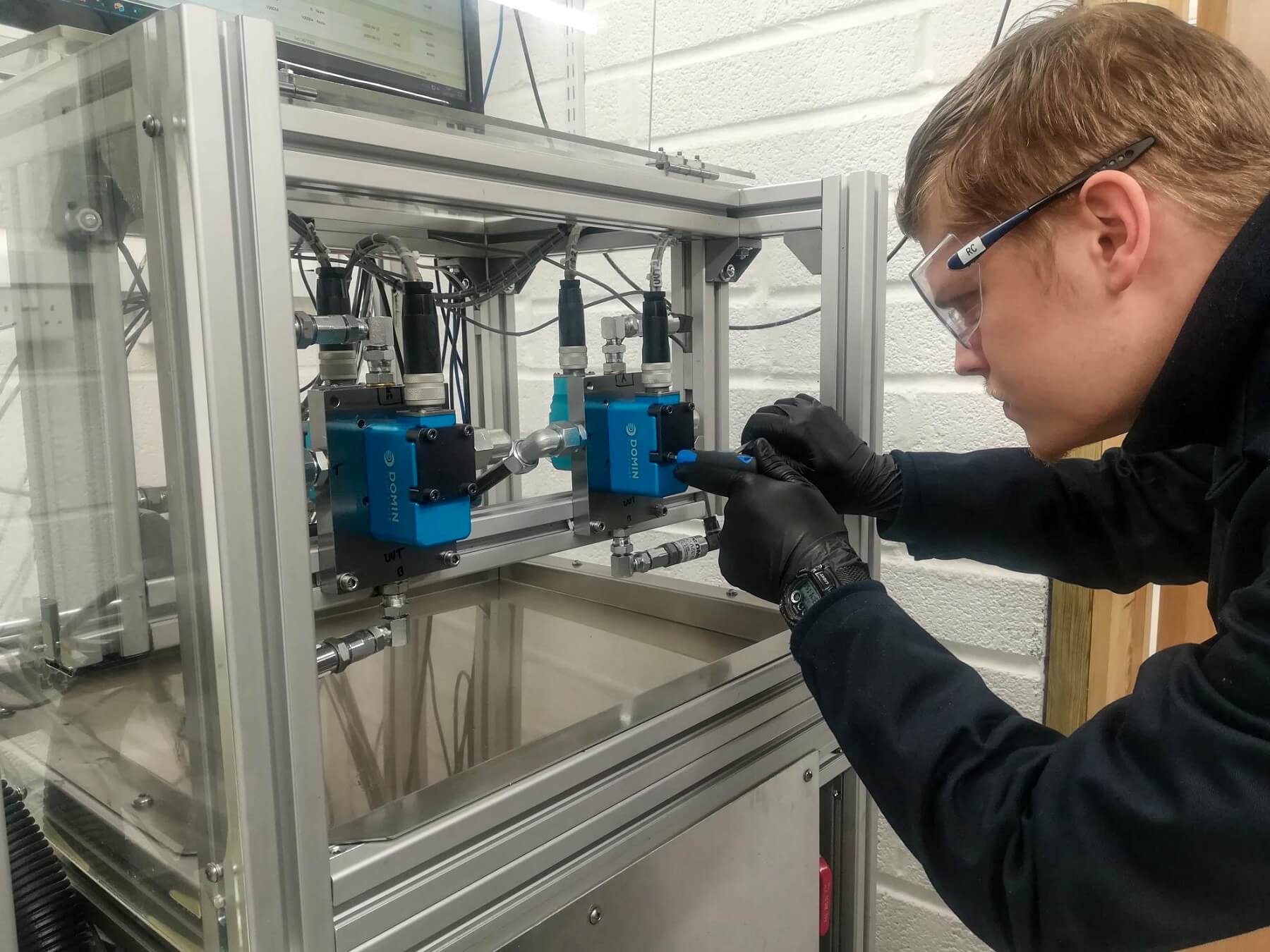

Digital tools, and the data they generate, can give levels of insight that traditional machining lacks. This is particularly key in heavily regulated industries such as aerospace, where accuracy and efficiency are crucial at every stage. To support aerospace OEMs, Sandvik Coromant offers several solutions to improve machining processes and to ensure the quality and reliability of components. These solutions include the CoroPlus® Tool Library, which allows users to build and manage their tool inventory and features data on over 900,000 items from several cutting tool manufacturers. The cloud-based library allows aerospace component manufacturers and CAM programmers to easily create tool assemblies adapted for specific machining tasks or receive specialized recommendations for each application, saving valuable time by removing the need to manually find and input tool data and reduce the margin for error involved in sourcing data from different systems.

Digital tools and the data they generate can give levels of insight that traditional machining lacks, which is key in heavily regulated industries such as aerospace, where accuracy and efficiency are crucial at every stage.

Sandvik Coromant also offers CoroPlus Connected with Silent Tools Plus, enabling data-driven process automation to optimize output quality. CoroPlus Connected is particularly effective in complex processes such as production of jet engine components and landing gear, where visualization is difficult and operators may struggle to accurately see inside components due to their complicated structures or challenging materials. Silent Tools Plus adaptors are equipped with sensors that can measure important parameters such as height, temperature and load and transmit this data automatically to the machine, minimizing tooling setup and improving operator control when the tool is in cut.

Finally, Sandvik Coromant’s CoroPlus Machining Insights offers operators a centralized oversight of machine data, allowing them to visualize the process from start to finish. Real-time and historical reports let engineers see machine and tool use, errors and performance, giving insights into areas for improvement and process optimization. This can improve overall productivity and highlight risk areas in manufacturing.

Even as the aerospace sector continues to recover from some of the most disruptive events in history, it is also poised to evolve into a more digital, more sustainable and more future-proofed sector. Having the right tools that can productively machine the materials driving this future will be essential.