Allied Machine to Highlight a Variety of Cutting Tools at IMTS

Holemaking and hole finishing solutions for your applications

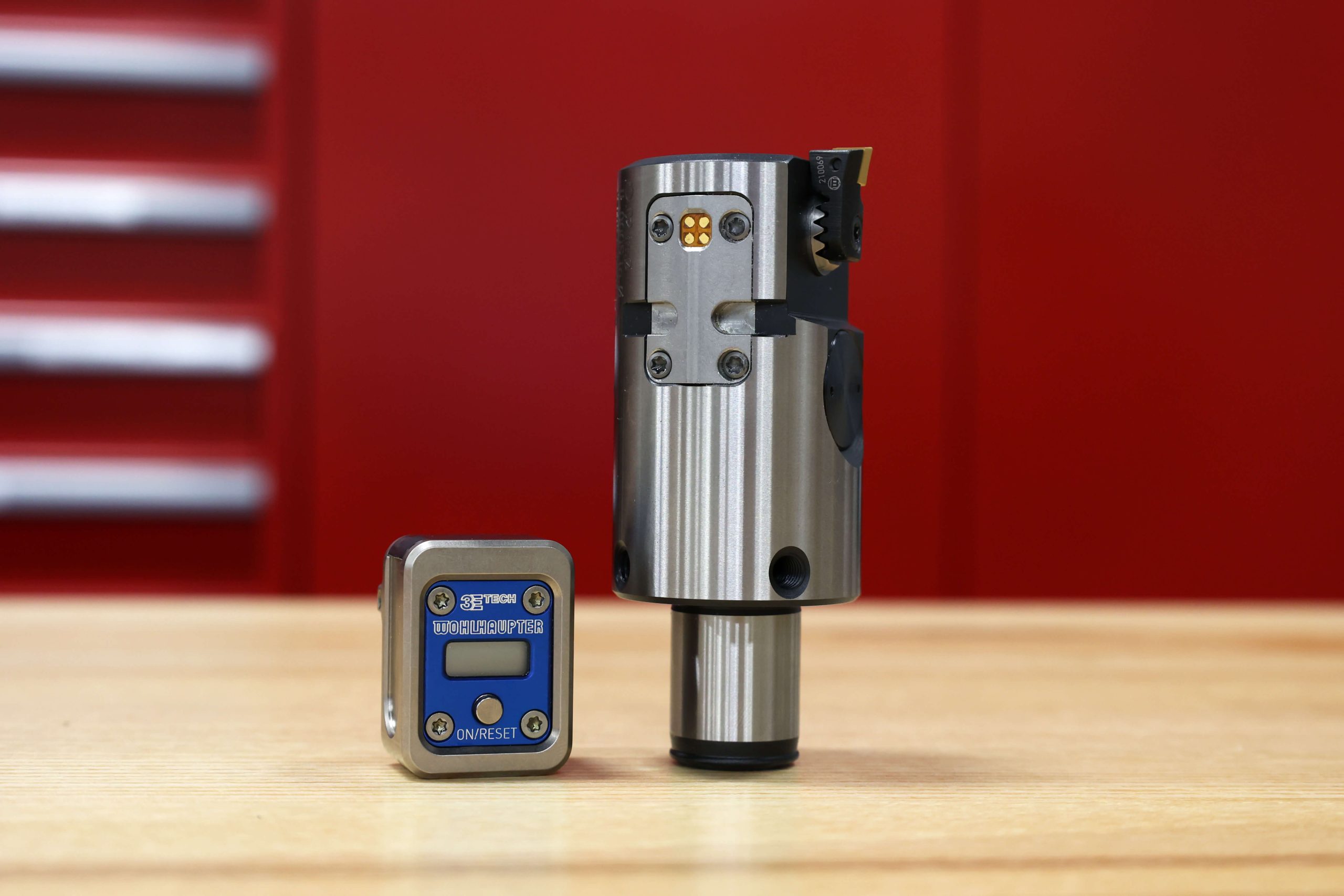

Chicago, IL – Allied Machine and Engineering, a leading manufacturer of holemaking and finishing cutting tools for the metal-cutting industry, is showcasing the Wohlhaupter 3ETECH+ digital readout module, T-A Pro Y series, and GEN3SYS XT Pro M geometry at IMTS in booth #431436 in the West hall.

With ease of use that is unmatched, the 3ETECH+ digital readout module is ideal for machinists looking to make diameter adjustments right at the machine. With premium visibility of one micron diameter adjustments, precision boring is easier than ever. High-production environments such as aerospace, heavy equipment and automotive greatly benefit from the enhanced digital readout module, which can be used on various Wohlhaupter boring tools.

Having an external, removable digital module also eliminates the worry of costly digital tooling components being harmed by cutting chips or high-pressure coolant. Wohlhaupter’s proven precision technology has aided in improving boring operations, and the following enhancements of the 3ETECH+ add to the benefits:

- Enhanced visibility with backlit OLED display and larger screen.

- Easier charging capabilities with rechargeable battery via USB-C.

- Multiple display color options for optimal visibility in any environment.

- Screen auto-rotate function to match the orientation of display module.

- Toggle between imperial and metric adjustment to accommodate all applications.

The new T-A Pro Y series serves as an upgrade to manufacturing processes, allows machinists to increase throughput in their cutting tool applications and ultimately gives users the opportunity to experience the benefits of the T-A Pro line at smaller diameters. Available in stub to 15xD and ISO-specific carbide grades P, K, and N as well as high-speed steel substrate X, T-A Pro Y series has a diameter range of 0.3739 inches – 0.4368 inches (9.50 millimeters – 11.09 millimeters).

Like the T-A Pro Z series, the Y series is offered in A and B body diameters and is available in both imperial and metric as well as flat and cylindrical shanks for all length options. With exchangeable tips and the ability to target specific materials and applications with an ISO-specific geometry selection on a single holder body, T-A Pro Y series gives machine shops the opportunity to upgrade to a superior system, allowing them to increase penetration rates, maximize tool life and take advantage of a more favorable cost per hole.

GEN3SYS XT Pro’s new M geometry insert is designed for all 300 series, 400 series and super duplex stainless steels in addition to other hard-to-machine materials in the ISO M group. With a substrate that provides the best balance of toughness and wear resistance necessary to excel in stainless steels, the M geometry is designed for improved chip formation while drilling high penetration rates within industries such as oil and gas, HVAC, automotive, construction, medical and pharmaceutical, and food and kitchenware. Adding the M geometry insert with Allied’s AM460 coating to the GEN3SYS XT Pro high penetration drilling system gives machinists access to an insert with industry-leading tool life in stainless steel applications.

For more details about Allied Machine’s holemaking and hole finishing cutting tool solutions visit: www.alliedmachine.com.