Do Yourself a Solid

SPONSORED CONTENT

Drilling is hard work. Here’s how to make it a little easier.

Holemaking is perhaps the most common of all manufacturing processes. Every day, holes are punched in orthopedic implants and heat exchanger plates, airplane components and automobile parts. Unfortunately, holemaking is also one of the more challenging metalworking operations. Poor chip evacuation. Shortened tool life. Holes that are neither round nor straight. Catastrophic failure. These are just a few of the problems plaguing machinists tasked with drilling holes in metal, regardless of whether the hole is made in super-soft aluminum or ultra-strong Inconel—successful hole drilling can be a tough nut to crack.

Why change?

The good news is that cutting tool manufacturers continue to develop increasingly effective drilling solutions. In fact, a seeming universe of such solutions exists, including indexable carbide drills, solid carbide, and carbide-tipped drills, and most recently, replaceable tip drills that take a best of all worlds approach to holemaking.

Still, none of these tools are inexpensive, at least when compared to conventional high-speed steel (HSS) drill bits. They might require you to modify your NC program, your toolholders, and especially your way of thinking. But as anyone who’s used one will tell you, they almost always provide a lower cost per hole than traditional, peck-peck-peck holemaking methods.

Perhaps your shop is still using Jobbers length or Silver and Deming drills. You’re not alone. They’ve been around for decades, are easy on the tooling budget, and forgiving of misalignment, cross-holes, runout, and drill walk. The downside is that HSS tools can only operate at one-fourth the cutting speed of carbide, and oftentimes far less.

Nor do HSS drill bits last as long as a carbide-tipped or solid carbide drill—when properly applied, you can figure on at least doubling tool life by switching to carbide. HSS drills almost always need a starter hole, another waste of precious machine time. And unless you’re using a HSS drill equipped with coolant holes (they’re around, but not common), you’ll be forced to peck if the hole is more than a couple diameters deep. Yes, HSS drills get the job done, as machine shops around the world will attest, but surely there are more effective ways to produce holes.

Anatomy of a high-performance drill

Let’s assume for a minute that I have your attention and that your shop is at least considering an upgrade of its holemaking capabilities. The good news is there are plenty of options available, but let’s start with one of the most recent advancements in drilling technology: modular, replaceable tip tools. Compared to solid carbide drills, they offer a much lower cost per hole, and compared to indexable-insert drills, offer better hole quality and, in most cases, greater performance. Here are some of the things to look for when shopping for one:

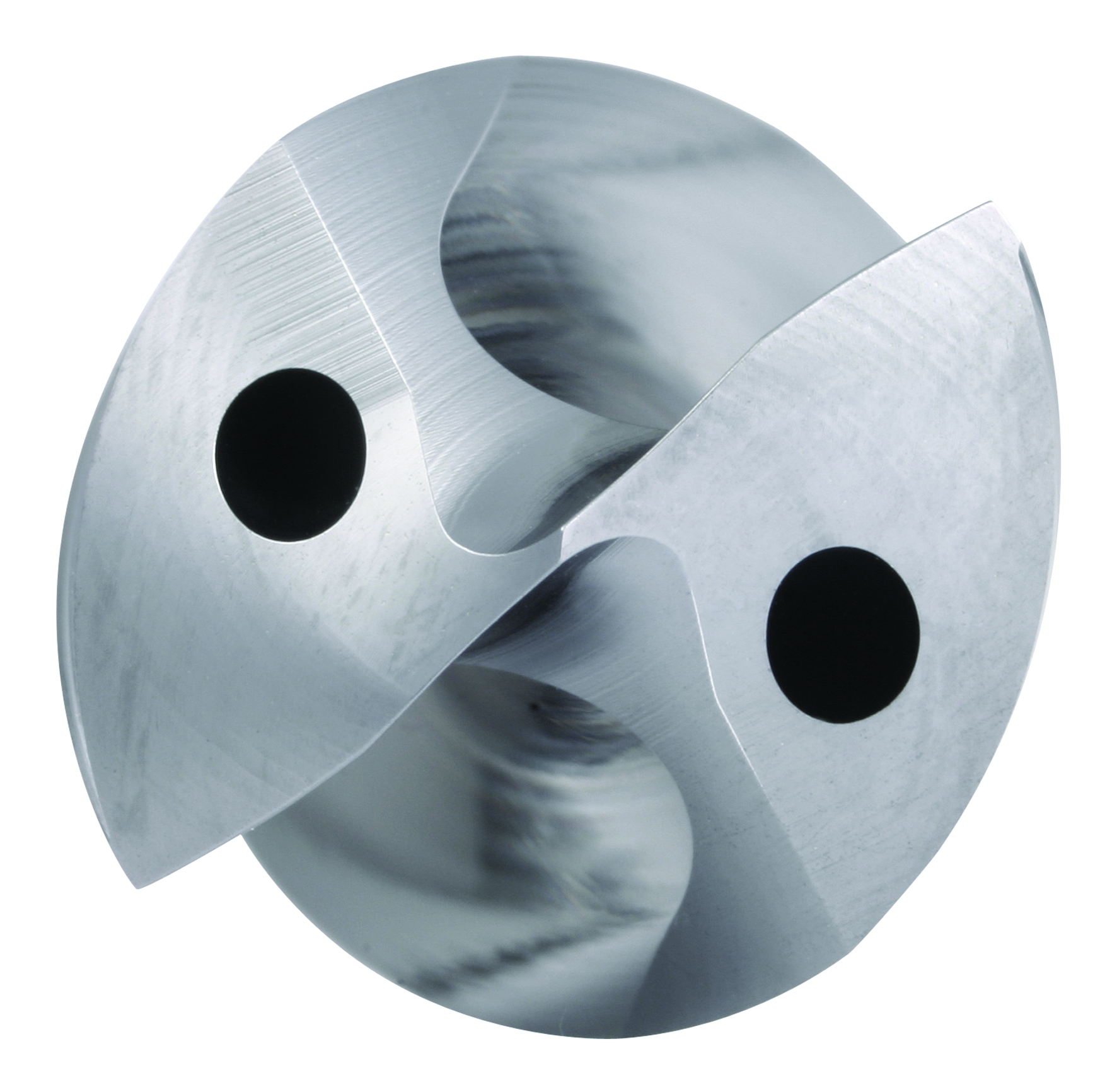

Chip flow

This is one of the biggest headaches with any drilling operation and is the main reason why pecking is so often needed with HSS drills. Without good chip flow, your drill is likely to end up as a melted blob of expensive metal and your workpiece in the scrap bin. Look for a replaceable tip drill with polished, almost mirror-like flutes, and extra-large gullets to eliminate any potential for chip packing, no matter what material you’re drilling.

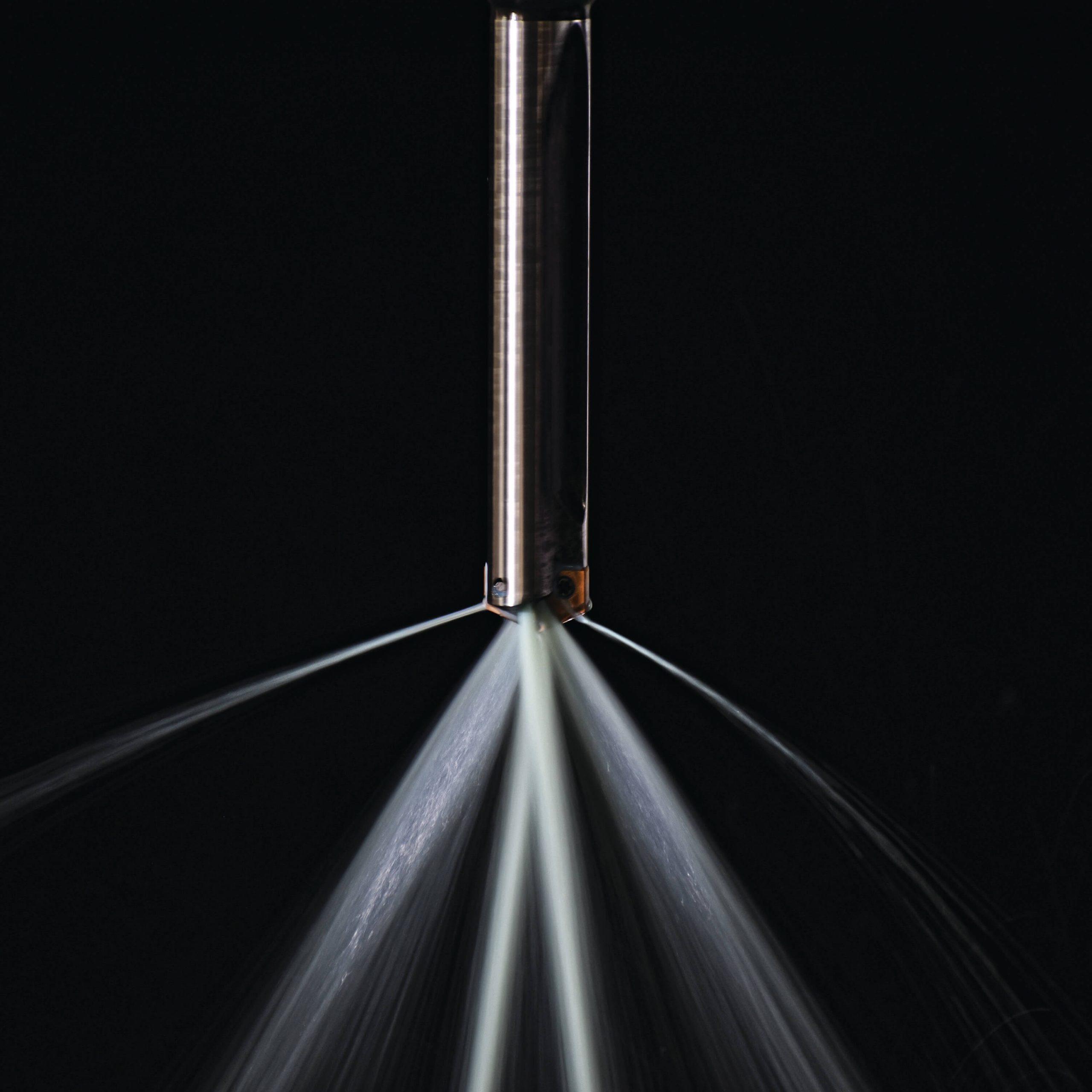

Coolant holes

Generous chip space is meaningless without equally generous application of cutting fluid. If possible, find a drill with two coolant holes per flute. When combined with a high-pressure coolant system (which any smart shop has these days), chip evacuation is assured, tool life improved, and penetration rates substantially increased.

It might seem obvious, but applying coolant through the tool—preferably at 1000 psi or greater—is a critical first step in improving your drilling operations. KenTIP FS has 4 coolant exits. The drill point has 2, and the 2 additional coolant exits in the chip flutes, delivering coolant to the rake face.

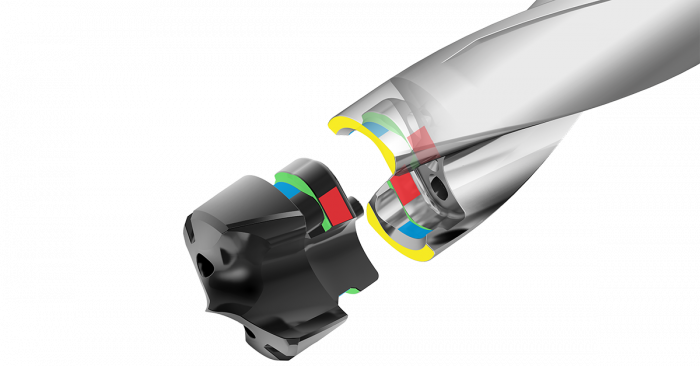

Robust interface

Let’s face it, modular and indexable tools with their tiny screws and awkward placement can be a hassle to work with. Worse, modular drills have gained—in some cases—a bad reputation for the tip working itself loose at the worst possible time. The best modular drills have a taper interface with large contact surfaces and a no-fail locking mechanism, one that’s both rigid and easy to change.

Grade selection

Unless your shop only machines mild steel all day, you’ll need a drill with a variety of carbide grades and coatings, as well as material class-specific point geometries designed for alloy steels, stainless steels and superalloys, and short-chipping metals like cast iron. This assures maximum tool life and hole quality and provides the lowest cost per hole possible.

Cost

A solid carbide tool’s higher investment cost is usually the sticking point for most shops and is why many prefer their tried and true HSS drills, regardless of any performance sacrifices. This is the beauty of replaceable tip drills. They are much less expensive than solid carbide, are available in a similar size range and there’s no more worry over reconditioning—when the tip has reached its end of life, just pop on a new one and recycle the old.

That’s not to say that solid carbide drills don’t have their place—they do, and are often the only option in extremely demanding applications—but thanks to their lower initial cost and nearly equivalent performance, a replaceable tip drill should be the first choice whenever possible.

Follow the rules

Whether CNC lathe or machining center, successful drilling depends on high-quality toolholders, good alignment, and of course, an excellent cutting tool.

Whether solid carbide or replaceable tip, let’s lay down some best practices for high-performance drilling. First off, runout is a killer with any rotary tool. Please take your Weldon shank holders and hide them in the deepest corner of the tool crib, then invest in a high-quality hydraulic or shrink-fit toolholder. These provide the best runout and gripping power available. And once the tool’s locked in place, don’t just assume it’s ready to go—use your presetter (another thing that all smart shops own) to verify it’s running true.

Since you now have a tool with coolant-through capabilities, be prepared to apply 1000 psi (80 bar) or higher of clean, well-maintained cutting fluid that’s been mixed according to the manufacturer’s recommendations. Then turn off your G74 peck-drilling cycle and get drilling. Unless you’re going more than 10XD, you probably won’t need a starter hole, but you’ll want to check with your cutting tool provider for the specifics.

Now is also a good time to start documenting your machining process—record when and why each tool was changed, how many pieces it made, and whether the cutting parameters were modified (and why) at any point during the job. Doing so will help you develop a stable and predictable process. And if your machine tool has tool life management, use it—you want to push your new drill hard but never past the point at which maximum tool life has been achieved. If you have any questions, give us a call. Until then, happy (and productive) drilling.

LEARN MORE ABOUT THE KENTIP™ FS MODULAR DRILL SISTEM

Author: Alex Schmidt, Senior Global Product Manager for Modular Drilling at Kennametal Inc., Latrobe, Pennsylvania