Edge Finders: Most Recommended Models of 2020

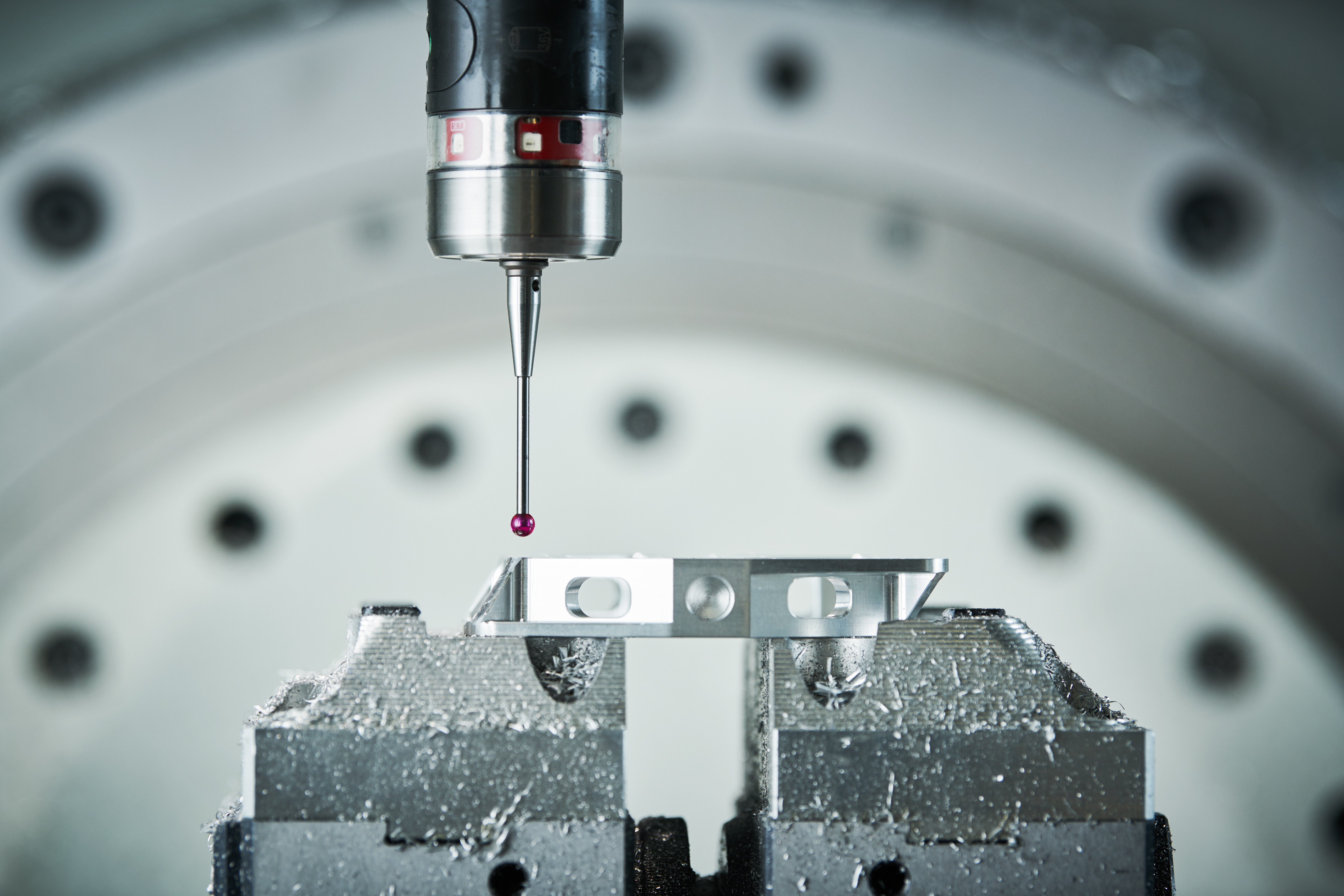

Before features can be machined onto any given work piece, the position of the work-piece must be defined. That is where the edge finder comes into play. The edge finder locates the edges of the given part in relation to the spindle of the milling machine or drill press. These highly effective devices ensure that your spindle is correctly positioned which means the rest of your operation will be set up for success.

Edge Finders come in different types and shapes, mechanical edge finders are the most common type in machine shops because of their ease of use and affordability. More advanced versions of the tool, such as electronic edge finders and 3D sensors, are also an option, but in this article we will discuss the standard model of the tool.

There are two main types of standard mechanical edge finders, single and double end. The main difference between the two is that double end edge finders, or combination edge finders, are essentially two tools in one. In addition to their use as a typical edge finder, the opposite, conical end functions as a center finder. Keep in mind, if your part is symmetrical, you can locate the center with your single end edge finder. In the video below, Ian Sandusky of Lakewood Machine and Tool gives step-by-step instructions for how to successfully find the edge. He also covers other tips and tricks including solutions for some of the most common mistakes made while using an edge finder.

To learn which edge finders are most popular among metalworkers, we asked the Practical Machinist community via social media to express their preference. Here are some models they recommended.

Recommended Single and Double End Edge Finders

Fowler 52-575-125 Conventional Edge Finder Set

This set has a measurement range of 7.878 to 8.27″ and is accurate to +/ – 0.00006″. It also features ceramic contact points to ensure durability and stability and the constant spring pressure ensures repeatability. The edge finders in this set are single end. You can find the combination or double end version of this tool here.

Starrett 827A Edge Finders, Single End

This Starrett edge finder is unique in that it is furnished with a protective case. The body and contacts are made of tool steel. The tool was hardened, ground, and lapped to close tolerances for diameter and concentricity. Without choosing favorites, this one seems to be the fan’s choice.

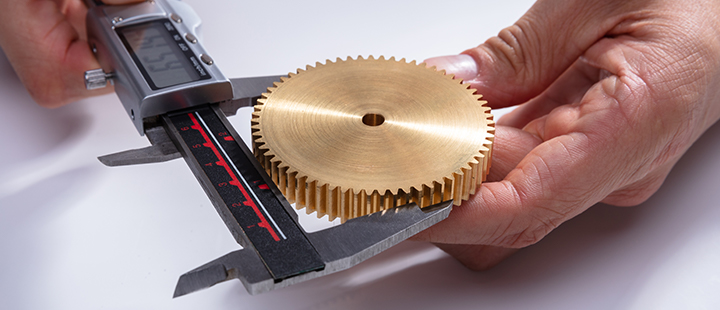

Brown & Sharpe 599-792-5 Edge Finder Double End

This double end edge finder is made from Hardness Rockwell C (HRC) 58-rated steel for increased durability. The tool features a 1/2” shank and 0.200” head diameter and can locate round or flat work to within .0005” accuracy.

Taytools Edge Center Finder Set with Single End, Double End and Cone Tips

Each tool in this set is made from hardened tool steel. The internal tension spring between the shaft and tip provides a flexible connection that is repeatable and durable. If you are looking for variety, this set includes both single and double end edge finders in multiple sizes.

This post may contain affiliate links. Please read our disclosure for more info.

5 Comments

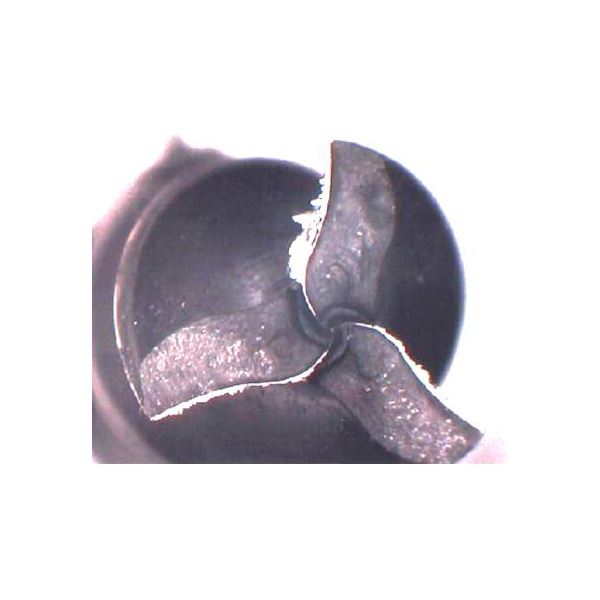

Double ended edgefinders presents a problem when the end inside the collet shifts, making it difficult to remove the edgefinder. Pulling the edgefinder against the shifted part can damage the unit.

I usually push it out the other side.

You are correct, my favorite has a single .200 end with a .375 shaft. I have been using this one since 1968 and still is almost good as new.

Good video. You forgot to mention checking the run out of the shank before you can rotate the spindle to pick up your zero.

No Audible Edge Finder mentioned!