This year, the company took a major step that represents both a renewed commitment to composites machining and an advance from its practice so far. For the first time, the company purchased a large-travel, precision five-axis machine tool that was chosen particularly with composites work in mind. The steady increase the company has seen in composites machining coupled with the extent to which it expects customers to favor composites for new parts in the future led to the conclusion that GTC’s capacity for composites machining ought to expand. Specifically, the company wanted the level of capacity represented by a metalcutting machine tool that just happened to have the right set of features for tight-tolerance machining of composites.

What features are those? There are several. For a machine tool intended for composite parts, the company says the beginning is simply the travels.

High Ways

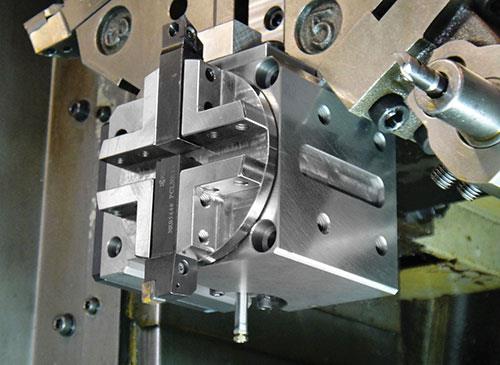

The new machine is a Diamond 30 five-axis gantry-style machining center from Parpas. Both of the machine’s rotary axes are in the spindle head, meaning that the spindle is able to move and pivot around the part while the part itself doesn’t move.

Composites machining is often inherently five-axis machining, notes General Tool CTO Greg Kramer. From a design standpoint, part of the very appeal of composites is the ability to make contoured forms in monolithic pieces. Parts GTC machines therefore typically include tight-tolerance features in need of machining at various angles, sometimes combined with contoured milling tool paths. In the past, CFRP parts such as large F-35 ducts required various setups even on one of the company’s larger five-axis machines to let the machine reach all of the part’s critical features. But the 3,000-by-2,600-mm travels of the Parpas machine are large enough to let the machine reach all the way around these parts, increasing efficiency by performing all the necessary machining in one setup.

Other features making the machine effective for composites relate to its structure. A U-shaped design for the base and frame places axis drives and the way systems far above the work area, near the machine’s ceiling. Mr. Kramer says this is beneficial because flood coolant during machining tends to carry the dust from machining carbon-fiber composite into mechanisms located below the cutting. Machine tools running composite parts throughout his shop filter coolant to capture this dust, and they feature protected way systems, but in spite of all of this, disassembly of the machines for maintenance inevitably reveals carbon dust infiltrating these systems. He says getting the ways up out of the way (so to speak) might be the best solution to this problem.

In addition, on the Parpas machine, this same structure is monitored with temperature sensors feeding data to the CNC, and it is cooled during operation with refrigerated air. The result Mr. Kramer expects is a dimensionally stable machine tool, and that stability is even more important for composites than for metal, he says. Thermal expansion of a metal machine might be no concern if the metal workpiece is similarly expanding. But CFRP, given its low expansion coefficient, is a different matter. The machine that can be protected from heating up will be more likely to hold fine tolerances on these composite parts.

One other, more commonplace feature of the machine is also important, he says: spindle-mounted probing. With a probe, the Diamond 30 machine is equipped to perform some of its own in-process measurements. Of course, many machining centers are equipped for probing, but the much older machine tool this machine replaced did not have that capability. Since a composite part is a workpiece that already has a significant amount of value built into it before the shop even receives it, the machining process for such a part poses far more financial risk than a process that begins with a square billet of metal. Machining routines for CFRP parts as valuable as the ones GTC produces demand in-process inspection to confirm accuracy, and machining personnel here are accustomed to performing the inspections manually. Probing thus will increase efficiency, because it will automate the process of safeguarding the part against error.

Tooling Opportunity

The new machine might lead to other process advances as well. Specifically, it might in some cases open the way to more cost-effective choices in cutting tools.

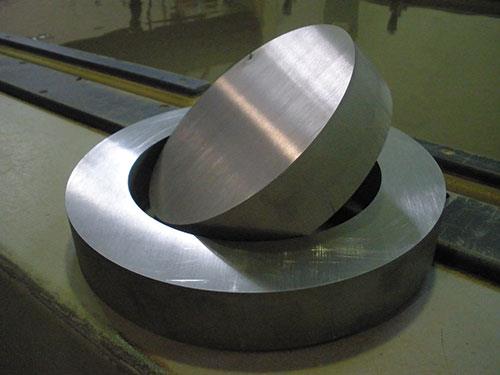

Over the years, the company has experimented extensively with tooling in CFRP. Its findings have led it to favor diamond-abrasive tools used with through-the-tool, high-pressure coolant delivery. Scott Brown, GTC milling strategist, and Chuck Shannon, programmer, were tasked with overseeing the startup of the new machine and production of its first composite parts. As they have before, these men created light and fast tool paths for the diamond-plated tools. However, this tooling poses challenges, they say. Specifically, Mr. Brown cites the danger that carbide dust might bind up in the abrasive grit, eliminating the effectiveness of the tool in the midst of the cut.

GTC machinist Eric Leder can attest to this. Speaking to me at one point while the machining cycle ran for a CFRP part (not on the new Parpas machine, but on a machining center older than this), he kept close to the machine in case he heard the sound of this binding. That failure is uncommon, but it happens just frequently enough to justify the machinist remaining alert to its occurrence.

In the particular part he was running, he says one hole type actually proved so conducive to tool binding that the shop ultimately abandoned an abrasive tool for machining the feature. It switched instead to a more conventional carbide drill, albeit with a special grind geometry.

Such a switch might seem straightforward. For a part intended for aircraft, however, making a change like this was no small matter. The process had been certified to make a flight-ready component using the previous tool, so changing the tool entailed recertification. In this case, that step proved to be more than worthwhile, because the carbide drill performed better and lasted much longer than the former tool. Through this experience, GTC discovered that the wear resistance of modern, standard cutting tools had advanced to such a point that certain metalcutting tools today are far better suited to CFRP than carbide tools of the past.

This is a valuable discovery for the company to have made just prior to installing the new machine for CFRP. Since this machine is new, everything about each part’s process on it is new. Existing parts sent to the machine will get programs and processes that will need to be certified as though the parts were new. As a result, on each of these parts, the choice of cutting tools is suddenly wide open. GTC is as free to experiment with new cutting tools for composites as it has ever been. In particular, it is free to explore the extent to which alternatives to diamond-abrasive tools might now be able to do the work more effectively, further adding to efficiencies it will realize on the composites-equipped machine.

The new machine was chosen for its potential effectiveness at machining composite parts. It will join other high-end machines at General Tool Co. that are available for machining critical components in either composites or metal.

GTC’s machining of defense-related CFRP components involves features that have tolerances comparable to those of critical parts in metal.

Features of the new machine that make it suitable for composites include large travels so that a five-axis part can be set up just one time, as well as protection of the ways via a design that elevates them high above the work.

GTC uses diamond-abrasive tooling routinely in composites machining, but this tooling is not without its challenges. The new machine will provide the opportunity to evaluate alternate tooling choices.

——————————————————————————————————–

Article From: 9/1/2016 Modern Machine Shop, Peter Zelinski, Senior Editor

MMSOnline Blog

Click Here for a free subscription to Modern Machine Shop magazine.

Click Here to subscribe to the MMS Extra monthly e-newsletter.

This article is reprinted with permission from Modern Machine Shop Magazine, and is protected under U.S. and international copyright laws. Modern Machine Shop Magazine is protected under U.S. and international copyright laws. Before reproducing anything from this Web site, call Gardner Business Media, Inc. (513) 527-8800.