Essential Inspection and Measurement Tools for Machinists

Inspection and quality control go hand in hand. Quality control practices ensure that requirements for any given manufactured part are met. Achieving accuracy is especially important in this industry, so make sure your metrology toolkit is well rounded with reliable, quality tools.

A machinist’s measuring tools should be handpicked with consideration. It can be easy to go down the rabbit hole and purchase too many unnecessary tools, so here is a practical list of measuring tools you’ll need in your metrology toolkit. When it comes to the most frequently used inspection and measurement devices, we recommend investing in high-quality tools as they will be staples for years to come.

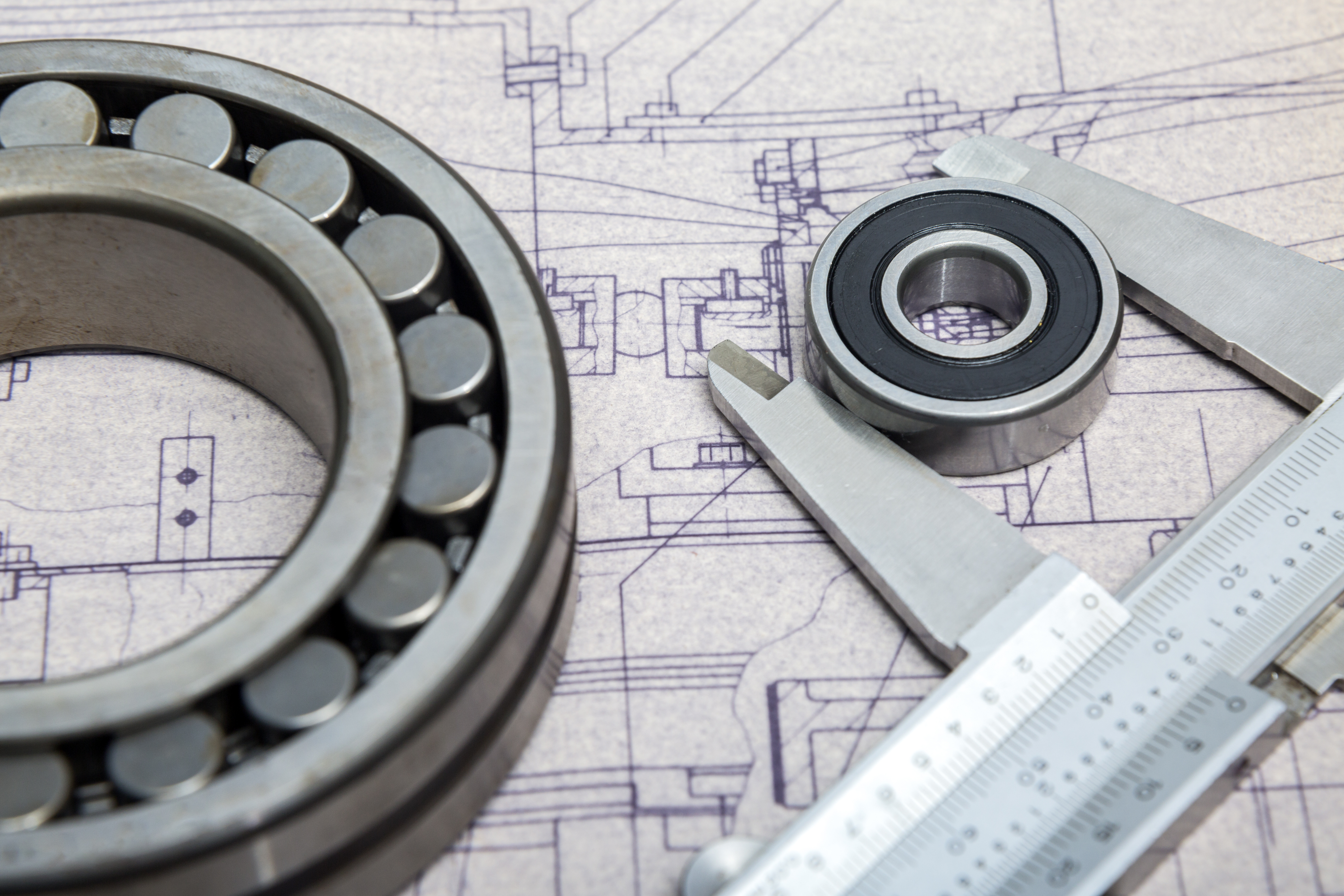

Calipers

It’s safe to say calipers are probably the most common tool in a machinist’s toolbox. The precision instruments are used to measure both internal and external distances. To learn a little more about the different caliper models – dial, digital and Vernier – check out our article What Type of Caliper Should You Use?

Our Recommended Option: Mitutoyo 500-197-30

This Mitutoyo Caliper measures 0 to 8” in 0.0005” increments. The advanced onsite sensor makes this instrument resistant to dirt, oil, and water. It also includes a protective case and an SR44 silver oxide battery.

Micrometers

Used for precise measurements of small objects, micrometers measure the depth, length, or thickness of a part. But there’s a catch: the part must fit between the anvil and the spindle of the micrometer, so keep in mind that the size of your micrometer matters. The standard micrometer will measure objects less than one inch. To learn more about micrometers, read The Ultimate Guide to Micrometers.

Our Recommended Option: Starrett T436.1XFL-1 Outside Micrometer

The tapered frame makes this tool great for measuring narrow slots and tight spaces. The knurled friction thimble helps provide a quick adjustment capability and the satin chrome finish prevents rust and reduces glare.

Dial Test Indicator

A dial indicator reveals any run-out of the workpiece, which simply put is the misalignment between the workpiece’s rotational symmetry and the axis of rotation of the spindle. Want to learn more about dial test indicators before you commit to a model? Check out the Top 5 Dial Test Indicators of 2020.

Our Recommended Option: TESA Brown & Sharpe 74.111371 Interapid 312 Dial Test Indicator

This dial test indicator is great for measuring surface variations in narrow or recessed areas, with its rotatable, white face and carbide tip. The instrument meets Deutsches Institut Fur Normung (DIN) 2270, and Norme Francaise (NF E) 11-053 standards and includes a declaration of conformity.

Height Gages

The name pretty much says it all. These gages will help you determine the height of your part and are also used pre machining to mark parts. There are different models of height gages – which we cover in our article Height Gages Explained – to help you sort out which is right for your project.

Our Recommended Option: Starrett 3751AZ-6/150 Electronic Height Gage

The hardened stainless steel bar makes this tool very durable. It has a measurement range of 0 to 6” and is precise to 0.0005”. The instrument also features a lock that holds the slide in position and a fine adjustment thumb roll for precision measurements.

Surface Plates

Surface plate options are vast and can be quite the investment. However, having a small surface plate will improve the quality of your measurements as it provides a precision reference surface for layout, inspection, machining, or gaging. For more information, check out Guide to Surface Plates with Recommendations for Smaller Sized Projects.

Our Recommended Option: Starrett 81803 Crystal Pink Granite Toolmakers Flat

Great for layout work when gaging small parts. The size makes it easily portable for use anywhere in a machine shop. The surface plate is 12″ long, 8″ wide, 2″ thick, and will achieve an overall tolerance of 0.0001″.

With the tools listed above, you should be able to perform all basic measurement tasks. However, throughout your journey as a machinist, you’ll likely have to deal with projects that require tools designed to inspect specific features of a part. For example, if you are taking on a boring project, we would suggest you check out An Introduction to Metalworking Gages.

This post may contain affiliate links. Please read our disclosure for more info.