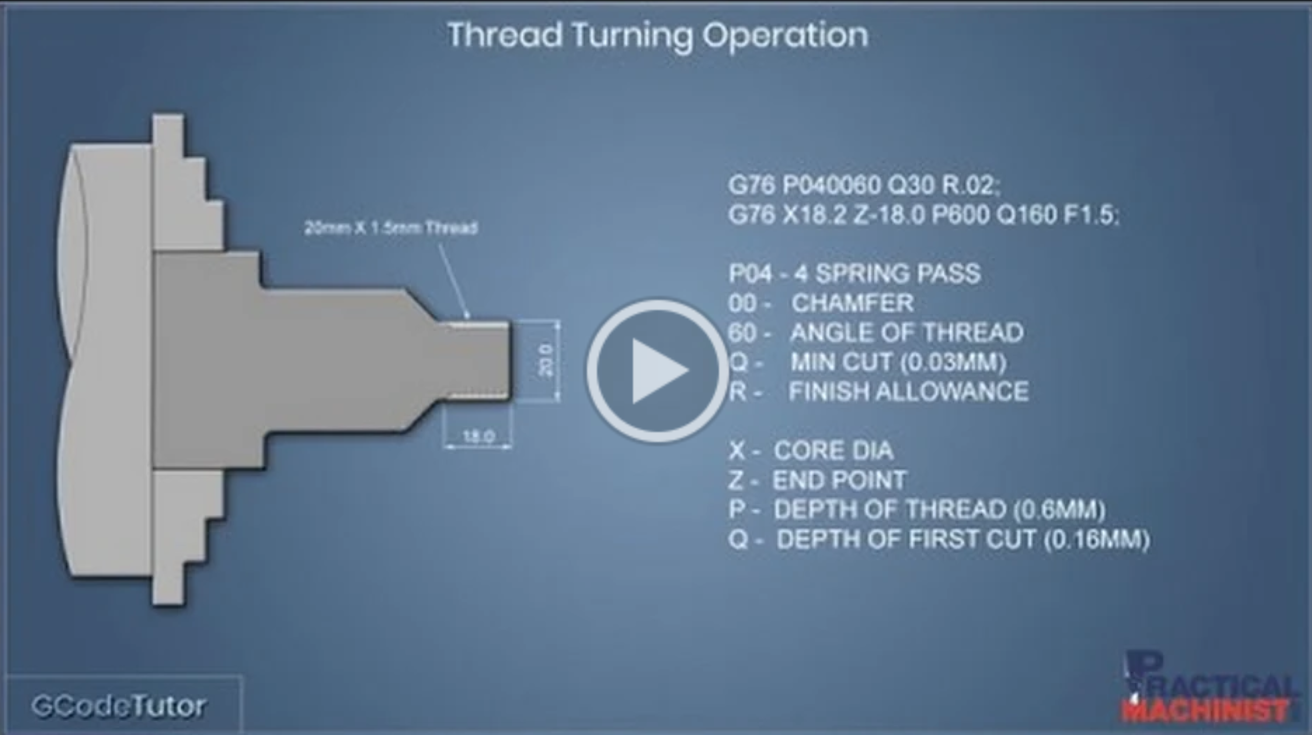

Follow These Steps to Program Thread Cutting on a CNC Lathe!

In the 6th video in this series, Marc, aka G-Code Tutor continues the series on manually programming a complete part on a CNC lathe using G-Code. This time, it’s about screw threads. There are a few ways to approach thread cutting on a CNC lathe by using G32, G92, or the more common G76. Marc walks us through, line by line on how to write the G-Code for this sequence. When programming the two-line version of the G76 cycle, the P and Q values aren’t calling a subroutine this time, but instead giving the machine information about the thread we want it to cut: G76 P(1)(2)(3), Q, R; G76 X, Z, P, Q, F; First line: P(1) = Spring passes P(2) = Chamfer P(3) = Angle of thread Q = Minimum cut R = Finish allowance Second line: X = Minor (core) dia of thread Z = Endpoint of thread P = Depth of thread Q = Depth of first cut F = Pitch of thread