G-Code Chamfering Fundamentals: Understanding 45° & 15°Angles

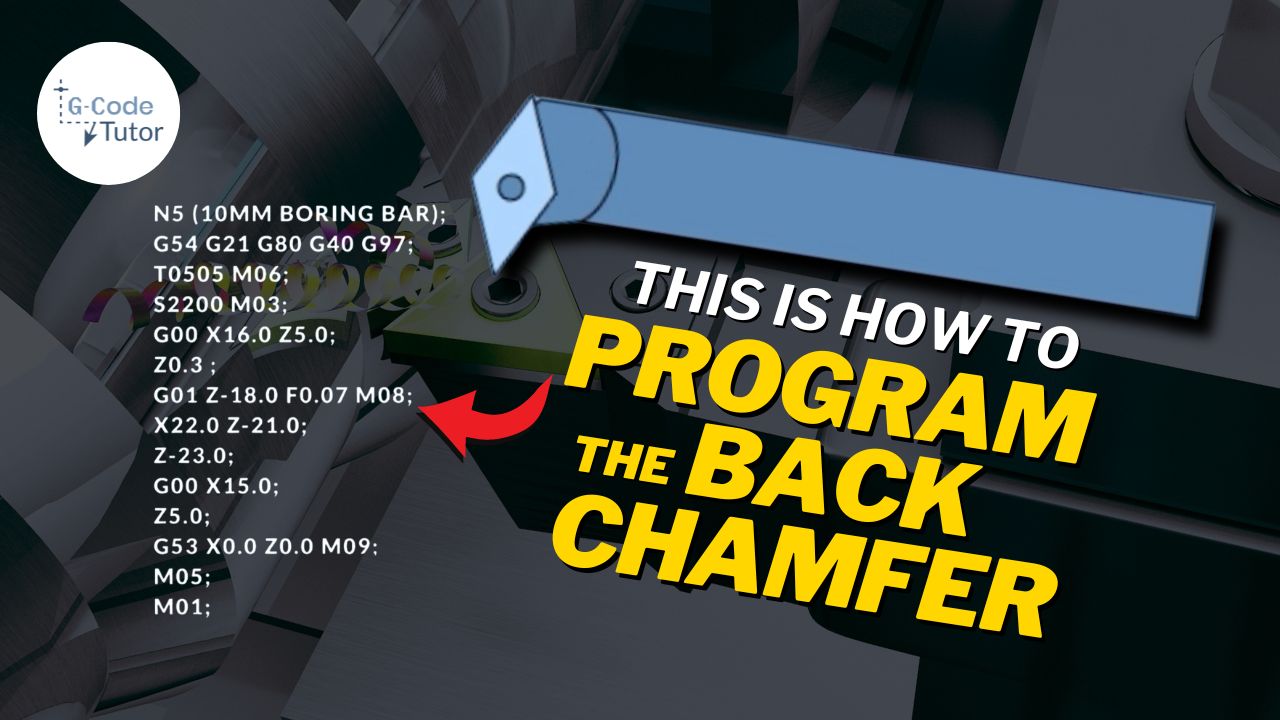

This month’s video from Marc from G-Code Tutor take a fresh look at the fundamentals of chamfering on both manual and CNC lathes. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Mastering the creation of chamfers is critical for any machinist. When forming a 45-degree chamfer, it’s important to note that the X and Z axes of the triangular cut are equal. However, on a lathe, the X-axis controls the diameter, not the radius, meaning a 2mm movement on the X-axis actually shifts the tool by 1mm, as material is removed from both sides of the part. Marc explains this concept in detail, helping machinists avoid common errors during machining. In addition, Marc demonstrates the process of chamfering with a 15-degree tool, illustrating how this angle impacts the necessary calculations. He methodically walks you through the steps, highlighting the importance of adjusting calculations based on the tool’s angle to achieve the desired chamfer.