Hog Heaven

SPONSORED CONTENT

Does your shop mill lots of aluminum? Lucky you. Most machinists love aluminum, and for good reason. It’s freer cutting than steel, less abrasive than cast iron, less grabby than titanium, and compared to Inconel and other superalloys…well, there’s no comparison. Unless you’re milling some super-abrasive high-silicon grade of aluminum—in which case diamond-tipped cutters should be used—tool life is often so good that some shops use HSS drills and end mills, saving the more expensive carbide tooling for the tough stuff. Granted, the high spindle speeds used with aluminum tend to send cutting fluid and chips everywhere, but that’s a small price to pay for excellent tool life and fine surface finishes.

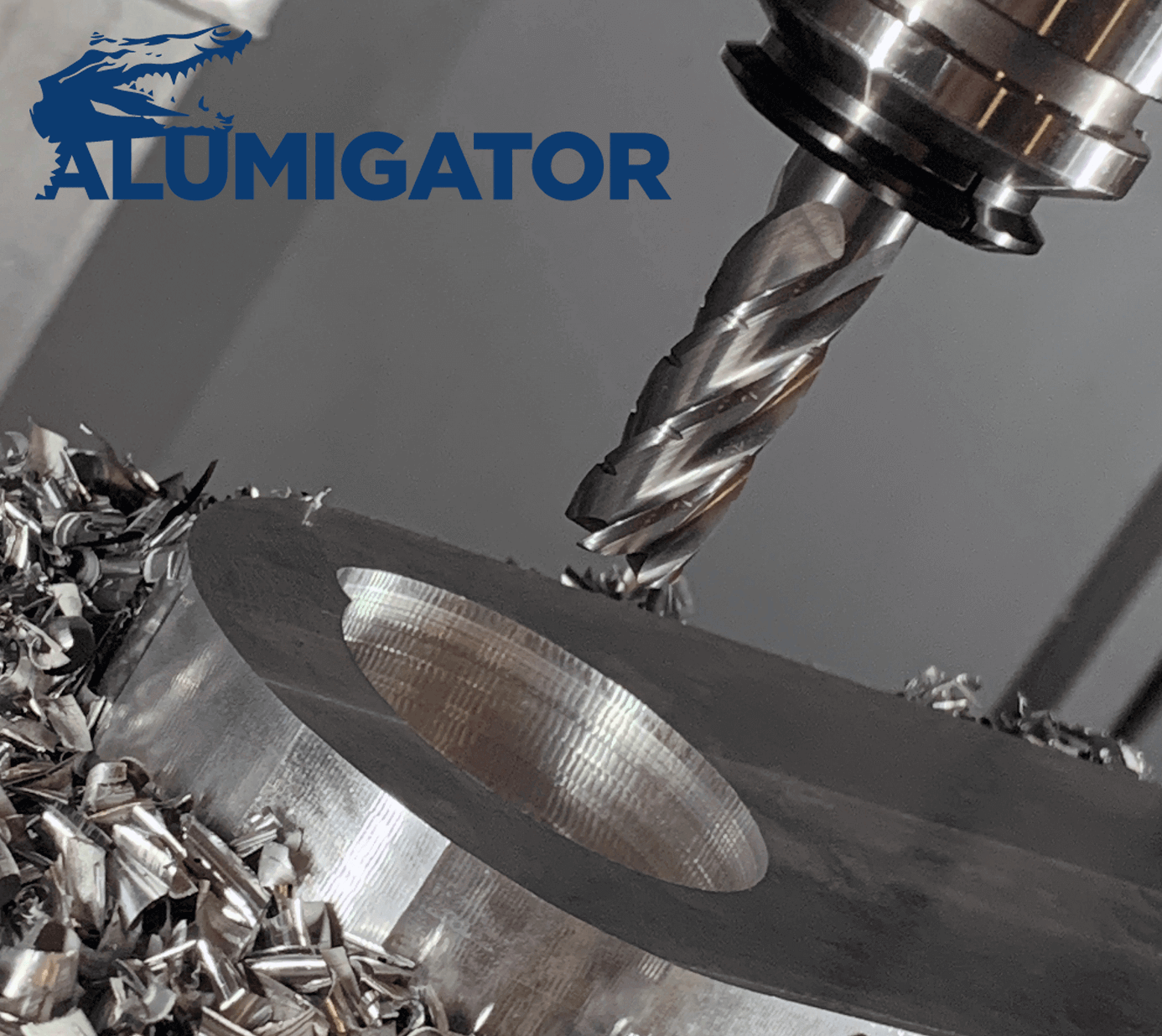

The challenge comes when you’re milling LOTS of aluminum. Think wing spars and bulkheads for commercial aircraft, where it’s not unusual to produce dumpsters full of aluminum chips each shift. Here, your job depends on ripping away massive quantities of metal quickly and reliably and doing so with no tool pull-out, no broken cutters from overfeeding, and no stopping the machine to clean out chip jams. Everything has to run flawlessly when you’re milling billets of aluminum longer than a pickup truck.

Stepping Up

Conventional wisdom says the best tool to hog aluminum is a high-shear, two or three-flute solid carbide end mill, one with generous chip gullets for efficient chip evacuation. A trochoidal, high-efficiency toolpath should be employed, and since tool pull-out and runout are a concern at high spindle speeds and cutter velocities, most experts suggest a shrink-fit balanced toolholder be used. As for flute geometry, some say that a corncob-style geometry is the most effective way to break up chips on these long axial cuts, while others say a smooth-flute “ski-carb” style end mill is best, particularly if surface finish is a concern.

The part about trochoidal toolpaths is correct. So, too, is the need for balancing at anything over 12,000 RPM. To achieve truly high-performance aluminum roughing, however, a different type of cutting tool is needed, one designed specifically for this demanding application. At extreme feedrates, for example, even the snuggest shrink-fit holder allows cutters to micro-creep, imperceptibly easing their way out of the holder until someone says, “uh, oh” (or worse) and hits cycle stop. This is the reason company Haimer first developed the Safe-Lock™ shank design, a system that has since been adopted by a number of leading cutting tool manufacturers.

Chatter can also be a problem at these velocities. The solution is two-fold. For starters, a variable-pitch flute design should be used to break up harmonics. Next, the cutter should engage with as much of the workpiece as possible, in order to stabilize it. This is achieved by increasing the number of flutes (thus increasing the number of contact points) and thickening the core—instead of two or three flutes, five provides the optimum balance of stability and metal removal.

Hail to the King

Hold on, though. Won’t this hamper chip evacuation and increase heat in the cutting zone? It might, unless you compensate with through-the-tool coolant, preferably delivered at high-pressure. A flute form and end face optimized for aluminum removal also help. As for the shape of the flute, corncobs do a great job at breaking chips, but let’s face it, they leave a terrible surface finish.

A better approach is a series of chip splitters strategically placed along the end mill’s entire length. When combined with specially-designed wiper facets, the tool can not only eject and break up chips like crazy but leave a surface that might meet Ra requirements without a second pass.

With chip splitters, coolant through the tool, a tapered core, and an innovative flute design, the KOR 5 is poised to change the face of aluminum machining

If any of this sounds interesting to you, it might be time for an end mill upgrade, especially if you’re working for a shop that needs to remove lots of aluminum in a big hurry. Head on over to www.kennametal.com and search for the KOR 5™ end mill, or call your local rep for additional details. You’ll be in hog heaven in no time.

3 Comments

Interested in these cutting tools!

I’ve ran several parts with the 3/8 kor5. I like the extra length over a standard endmill. Lots to grip when hanging out extra.

Cuts very well. Prefers deeper depth of cut for the extra engagement.

Takes lots of abuse. Chip welded it several times and could take a punch and carefully knock off the welding on a 1/2 plugged endmill. Shockingly abuse tolerant.

Great for roughing/semi finishing, honestly for my parts i finish with it.

Running on a haas vf2 10,000 rpm 20hp 1” depth, 0.075 radial. 400-600 Ipm in a Schunk tendo e w/reducer.

Last job was lots of roughing at 600ipm 0.875 depth 0.75 radial. 1.6” tool hang out (didctated by part) Put spindle load to about 90% 6061 6t. would have pushed a little harder to test it more but I did not want to push my setup clamping.

About above post.

I should say the chip welding was absolutely my fault