How I Programmed This CNC Part for a Perfect Fit

Getting CNC parts to fit perfectly isn’t luck—it’s all in the CAM programming. In this episode of The CAM Files, Jonathan from 2SM Performance takes on a precision challenge: machining a custom billet dog bone linkage for a Kawasaki KX125 dirt bike.

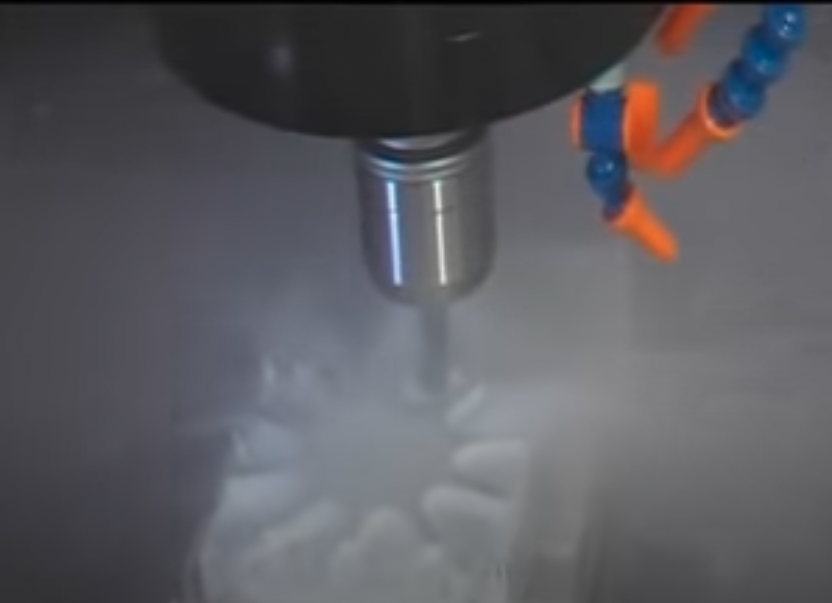

This rear suspension component has a critical job—connecting the shock to the frame and swingarm. Even a few thousandths off, and the fitment is ruined. With 6061 aluminum, Fusion 360 programming techniques, and tight tolerances, every step had to be dialed in perfectly.

How do you program for a perfect CNC fit? This video breaks it down:

✅ Stock setup & drop material considerations

✅ Work offsets & fixturing for repeatability

✅ Fusion 360 toolpaths for precision machining

✅ Finishing passes & chamfering for a flawless fit

After careful programming and machining, the final part was dead-on—passing QC checks with precision.

![Episode 40: Machining a Vane Pump [PROJECT VLOG] MST Thumbnails (1)](https://maintenance.practicalmachinist.com/wp-content/uploads/2022/01/MST-Thumbnails-1.png)