How to Program CNC Lathe for Center Drilling with G-code

This week, Marc from G-CodeTutor continues this series where he programs a complete part using G-Code on a CNC lathe.

This time, Centre drilling our part to ensure the 1/4″ drill does not wander from the centre line.

Marc starts by writing the safety line. This block of code puts the machine into a standard state ready to start cutting. If we stop the program during a cycle and restart from a different place in the program, the machine will assume the cycle is still active and do some unexpected things. The safety line is there to make sure the machine clears any active cycles, resets the datum, resets any cutter compensation etc. Everyone’s safety line is different depending on the machine and the needs of the machinist.

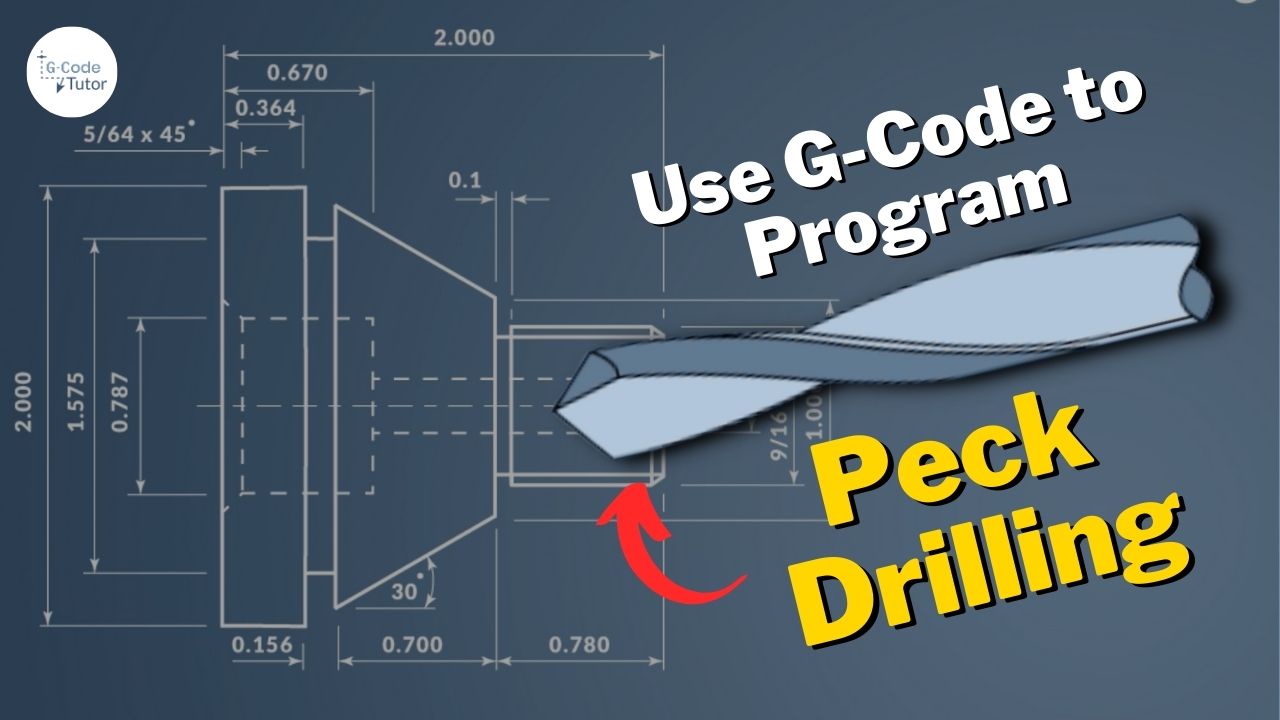

Marc selected a number 4 centre drill for this operation. He used his Machinist Handbook that is available for free on his site to see the dimensions of the centre drill options to help him select the correct size.

Centre drilling is usually performed with point-to-point programming, we don’t need cycles to drill one hole at a small depth. Marc demonstrates this style of drilling as he programs the rest of the sequence in the video.