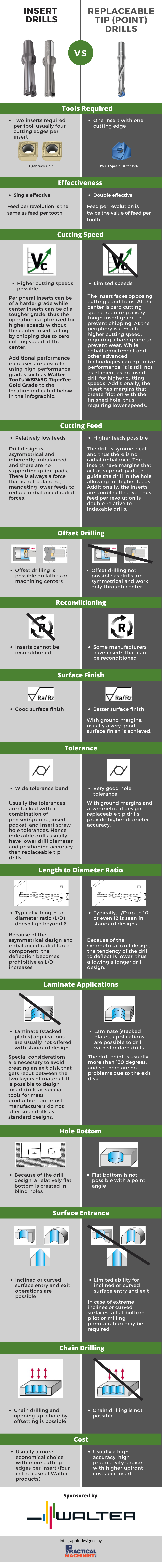

Infographic: A Comparison Between Replaceable Tip (Point) Drills and Insert Drills

SPONSORED CONTENT

Drilling is one of the most prolific manufacturing processes used in nearly every manufacturing shop. Typically, up to a diameter of ¾” (19mm) solid carbide drills are commonly used. But as the diameters get larger, the costs of a solid carbide drill becomes prohibitive and using indexable drills becomes a more practical and economical alternative.

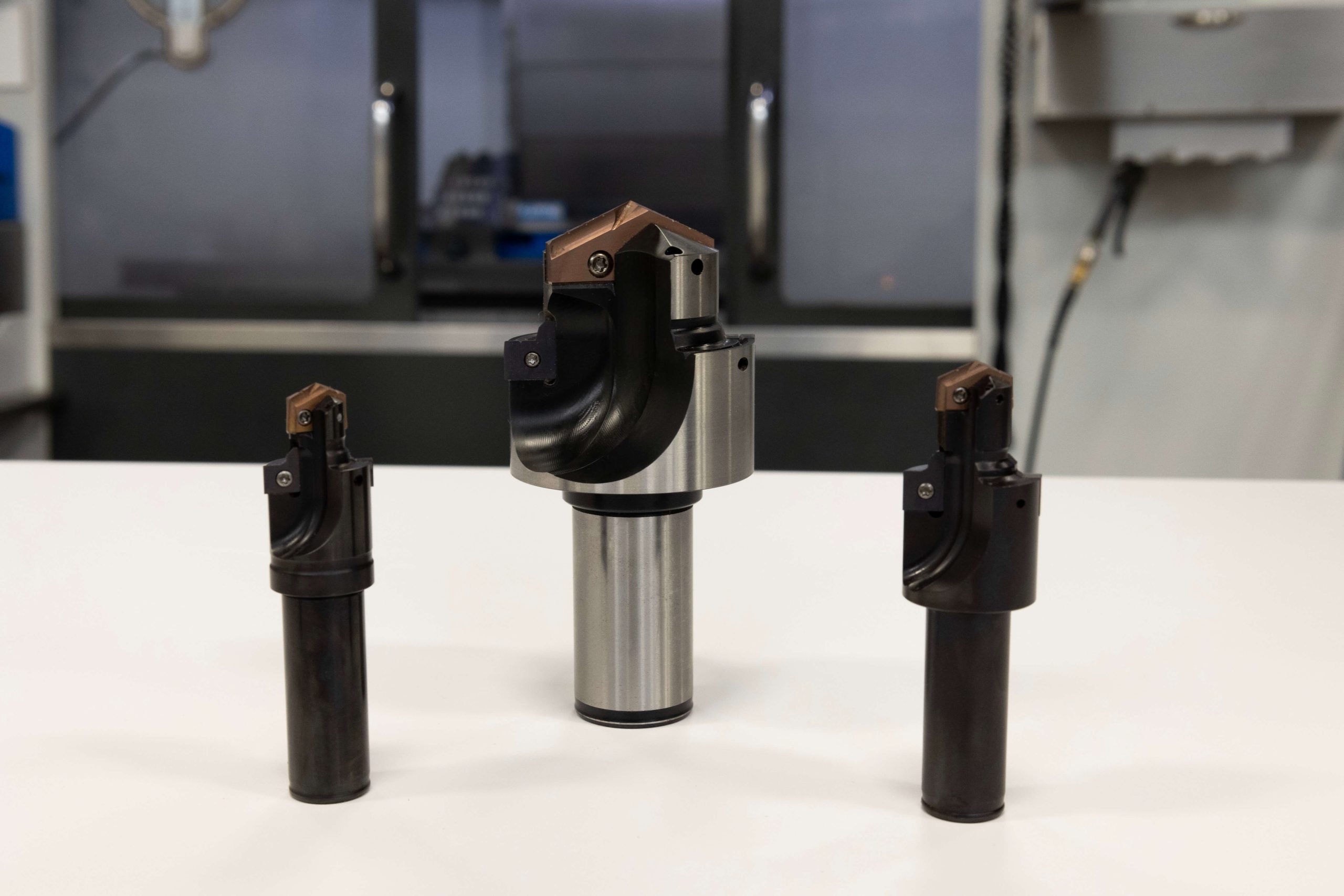

In the indexable drill category, two designs are quite universal regardless of manufacturer. First is the replaceable tip drill, also called a point drill. The second is simply termed an insert drill. Each design offers distinct advantages over the other from an applications perspective as well as an economic one. So, it is not always that one drill design is better than the other.

Here is a simple infographic that answers some basic questions you may have about the differences between replaceable tip drills and insert drills.

More information about Walter Tools’ insert drills is available on our YouTube Channel (D4120 Drills) – (D3120 Drills) or on our website (D4120 Drills) – (D3120 Drills).

More information about Walter Tools’ replaceable tip drills is available on our YouTube Channel (D4140 Drills) or on our website (D4140).

More information about the new Tiger·tec® Gold PVD grades for drilling is available on our YouTube Channel (WSP45G TigerTec Gold Grade) or on our website (WSP45G TigerTec Gold Grade).