An Introduction to Metalworking Gages

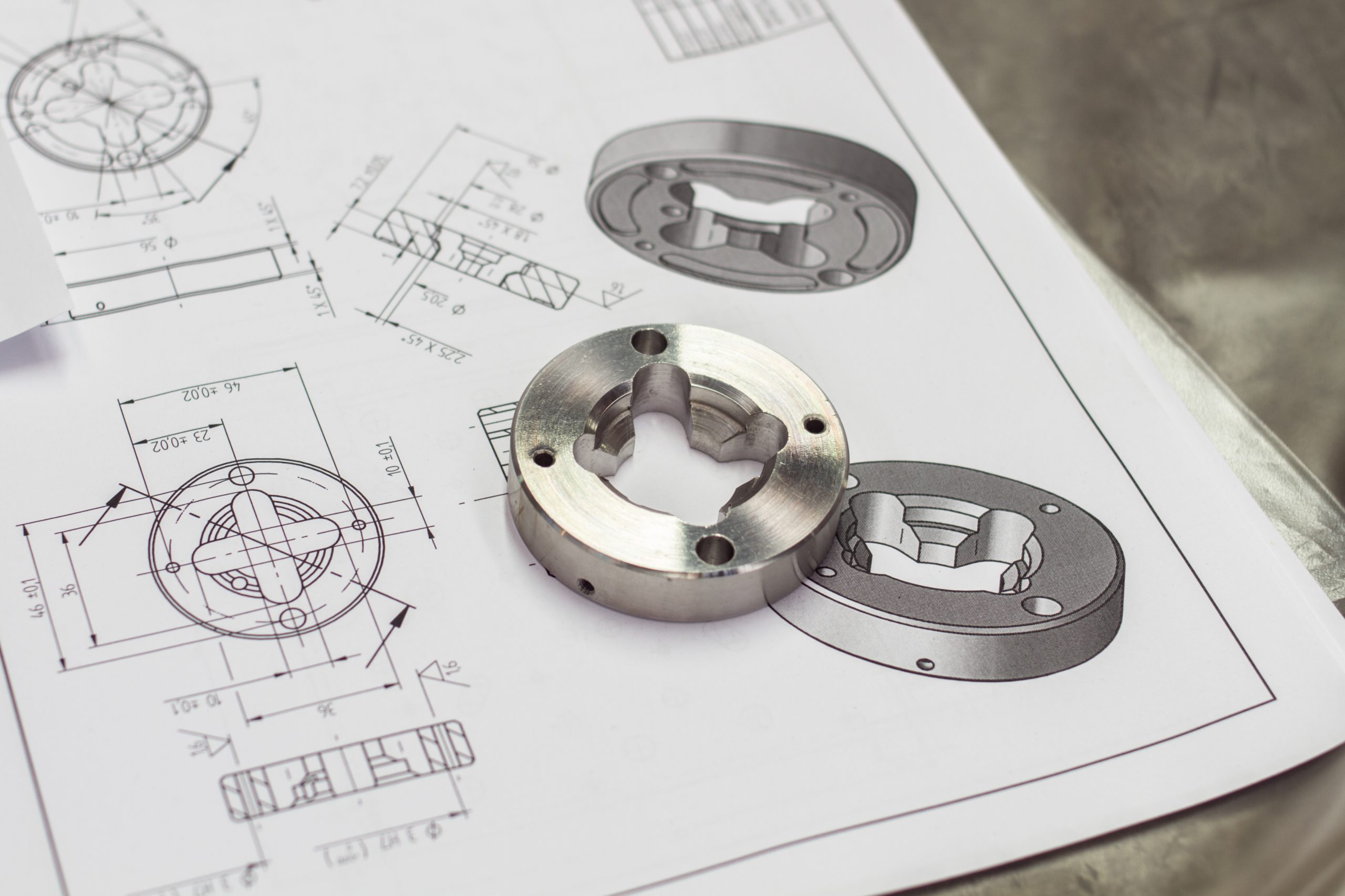

Gages are one of the most common measuring tools you’ll find in machine shops due to their versatility. As the name suggests, gages are used to measure different characteristics of a part or a machine, such as pressure, dimensions, levels and more. In metalworking, they are mostly used for dimension measurement. Bore, depth, height, ring, and plug gages fall under the dimension measurement category and are the most popular for machining processes.

Let’s look at each model and discuss what their function is within a machine shop.

Height Gage

Height gages are typically used to inspect finished parts. The gage is used to measure the height of the part and/or make repeated markings on the part. Height gages are a great compromise between accuracy and cost as they are more capable than calipers, yet less advanced than coordinate measuring machines (CMMs). Learn more about the anatomy of a height gage and the different types of height gages here.

Recommended Models

Mitutoyo 570-312, HDS Digimatic Height Gage, 12″ X .0005″/0.01mm, With Output

With a built-in electronic microprocessor, this tool is best for more sophisticated applications. This model allows for measurements up to 12”, but is offering in additional sizes should your project require it.

Starrett 3751AZ-6/150 Electronic Height Gage

Starrett makes both electronic and manual versions of this height gage, depending on your preference. With 0.0005” graduation, accuracy is this tool’s strong suit.

Bore Gage

These inspection tools are used to measure the internal diameter of machined holes or cylinders. Bore gages measure with high levels of precision and come in a variety of different shapes and models, such as inside calipers, inside micrometers, dial bore gauges, three-point bore micrometers and telescopic gages. Learn more about these models and their functionalities here.

Recommended Models

Though pretty pricey, the self-centering, self-aligning and extension functionalities make this tool highly desirable.

With a measurement range of 1.4” to 6″ and gradient spacing of 0.0005″/.001mm, your bores will be accurate to say the least. Carbide-tipped contact points keep this tool armed with abrasion resistance capabilities.

Depth Gage

Depth gages, also known as depth micrometers, are similar to bore gages because they both deal with measuring the dimensions of holes and other machined cavities. The difference is that depth gages, as the name suggests, measure the depth of the hole. A depth gage typically consists of an anvil, an indicating dial, and a probe assembly. Learn more about depth gages here.

Recommended Models

Starrett 440Z-6RL Vernier Depth Gauge, Ratchet Stop, Lock Nut, Micrometer Type, 0-6″ Range

This set includes 12 interchangeable rods capable of measuring depths of up to 12”. Achieve ultimate precision with the smallest graduation interval of 0.001″; with + or – 0.0001″.

This set has 12 interchangeable rods that are slightly bigger (0.157”) than the Starrett set above, but this does not impact accuracy as you can still measure almost any type of recess.

Go/No-Go Gages

Go/no-go gages are used to inspect internal or external diameters, threads, or forms. Unlike other more sophisticated tools, these gages are quick to use and do not require much skill. They are typically divided into two types: ring gages and plug gages.

Ring Gage

By going over cylindrical features, ring gages are used to inspect external part features such as diameter or thread pitches.

Plug Gage

This type of go/no-go gage is designed to fit inside a machined hole to measure internal diameters or threads.

The model you choose is completely dependent on the size of the internal/external diameters or threads you intend to inspect. These gages are designed to either “fit” or “not fit” and are used as a quality control measurement to determine whether a part is acceptable or not.

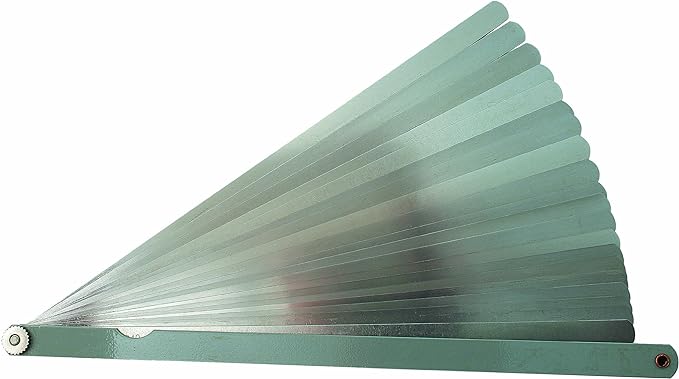

Feeler Gage

Also known as feeler blades, these gages are used to measure the gaps between machined elements. If the blade moves too freely within the gap, stack the blades until you reach the required resistance. Adding these measurements together will allow you to determine if the clearance is within the desired range.

Recommended Models

CTA Tools A311 25-Blade Extra Long Feeler Gauge

The extra-long length is best for long reach applications. This model comes with 25 removable blades, each 12” long, that have metric markings.

Made with a smooth finish to ensure comfortable handling, this model is marked in both metric and imperial.

Now that we have covered the models, it’s important to point out that gages are susceptible to wear from use over time. The harshness of the environment will impact the significance of tool wear and thus the frequency in which the tool will require calibration. Gage calibration ensures quality tool performance and higher accuracy of measurements. If you’re interested in learning all things gage calibration, check this out.

This post may contain affiliate links. Please read our disclosure for more info.