KYOCERA SGS Precision Tools Reveals Coolant-Through Expansion of Popular 7-Flute End Mill Line

KYOCERA SGS Precision Tools announces a large expansion of the popular H-Carb seven-flute high-efficiency end mill series with over 400 new coolant-through options.

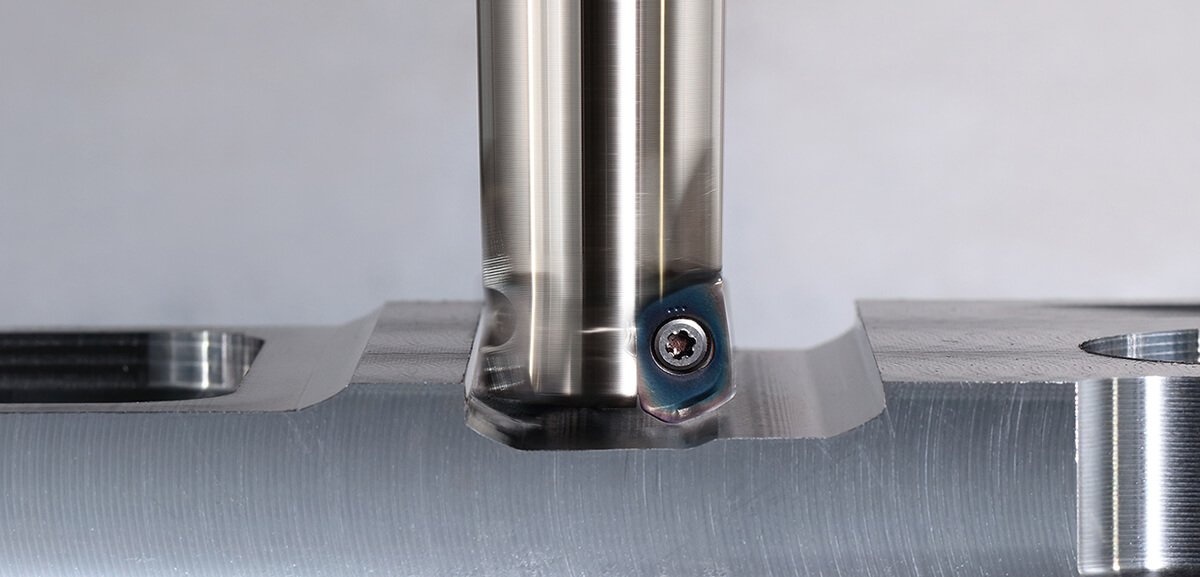

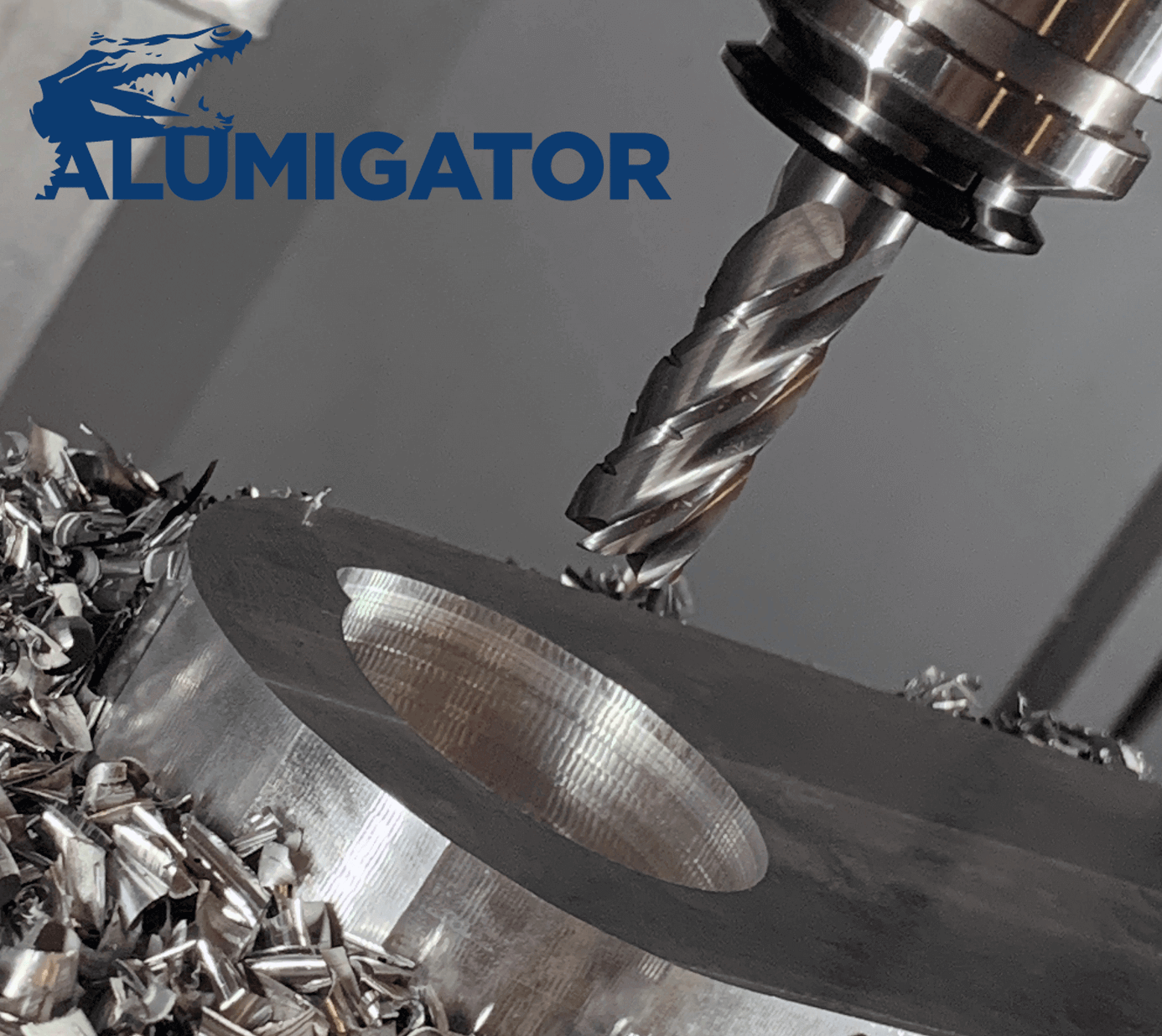

Available in various lengths of cut, the new H-Carb Series 77 coolant-through end mills specialize in deep axial trochoidal and high-speed machining applications. The new coolant-through varieties offer better wear, surface finish, and chip evacuation when pocketing or slotting. The H-Carb’s specially designed core and flute design improve rigidity and chip flow while reducing deflection. The seven-flute design allows for superior finishes at higher speed and feed rates versus 5 and 6 flute tools.

The expanded H-Carb portfolio features specialized Ti-NAMITE®-A or Ti-NAMITE®-M coating technology for increased wear and abrasion resistance extending tool life dramatically to tackle a wide range of materials and applications. The Chip Breaker profile is standard option with a wide range of square end and corner radii options offered to meet a variety of machining specifications.

Benefits:

– Heavy-duty core and specialized flute design for improved rigidity, chip flow and reduced deflection

– Heavy-duty core and specialized flute design for improved rigidity, chip flow and reduced deflection

– Chip Breaker profile standard in portfolio and aids in chip flow, especially in deep pocketing operations

– Deep pocketing and slotting capability using various lengths of cut offered by applying a trochoidal tool path

– Coolant-through options are available for better wear, surface finish, and chip evacuation when pocketing or slotting

– CAM programming methods using high-efficiency machining by applying trochoidal tool paths and incorporating constant cutter engagement

– Available in 3 lengths of cut (2.5xD, 3xD, 4xD)

– Available in Ti-NAMITE®-A and Ti-NAMITE®-M coatings for a wide range of materials and applications

Features:

– Cutting Diameter: 1/4″ – 1″ / 6,0-25,0

– Length of Cut: 5/8″ – 4″ / 15,0-100,0

– Overall Length: 2 1/2″-7″ / 63,0-170,0

– Shank Diameter: 1/4″-1″ / 6,0-25,0

– Corner Radius: 0.015”-0.120” / 0,3-4,0

– Coating(s): Ti-NAMITE®-M, Ti-NAMITE®-A

– Special Options: Chip Breakers, Coolant-Through

Material Applications:

– Steel ≤ 45 HRc

– Stainless Steel ≤ 45HRc

– Cast Iron ≤ 45HRc

– High-Temp Alloys

– Titanium Alloys ≤ 45 HRc

Industry Applications:

– Aerospace

– Medical

– Power Generation

– Automotive

– Mold & Die

– Casting & Foundries

– General Engineering