Machining Brass: A New Benchmark in Productivity

Image credit: Copper Development Association Inc.

A recent study from the Copper Development Association Inc. (CDA) revealed that U.S. machine shops are potentially underutilizing the machinability of brass by as much as 85 percent in their part processing operations.

The study highlights how the material can impact job efficiency and profitability in several ways:

- Cutting down machining time

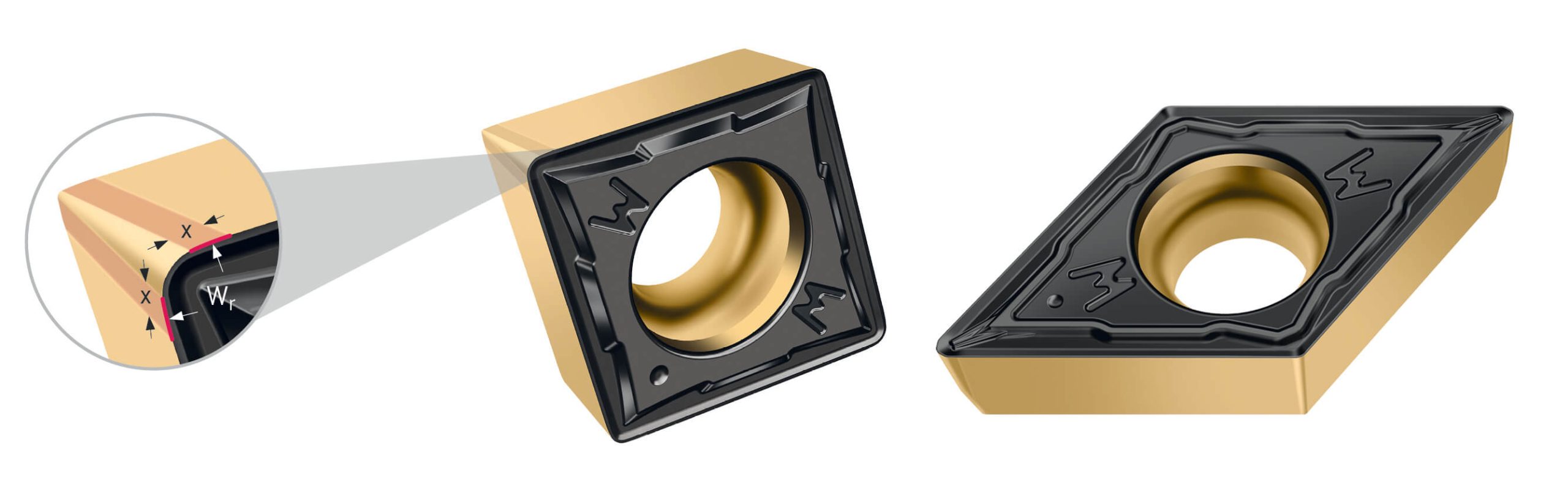

- Reducing the tool wear

- Improving surface finish

- Reducing chip formation.

The study also asserts that alternative materials such as steel and stainless steel lack the competitive high-speed machining advantages derived from brass.

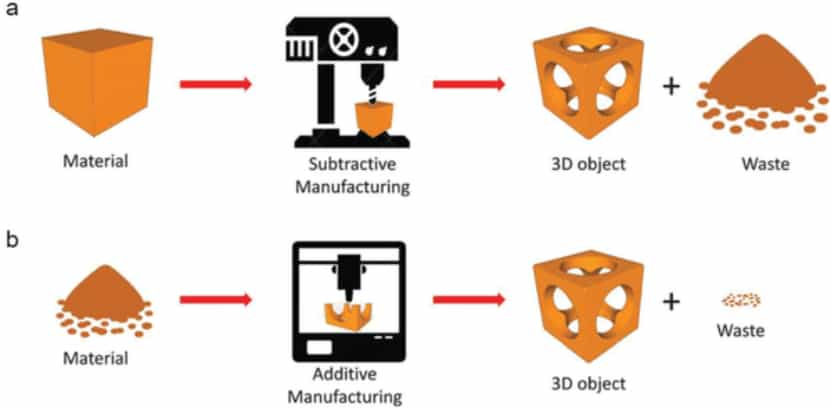

Brass is also 100% recyclable, allowing manufacturers to recover a good portion of the initial raw material cost through scrap buy-back programs. The chips can be used to produce new material, making it very sustainable for the planet.

Read more about high-speed machining of brass and the high-speed machining advantages of brass vs steel.