Maximizing Efficiency and Precision with Walter Tools Grooving Systems

Are you looking to enhance the performance of your grooving and parting off operations? Look no further than Walter Tools Grooving Systems. With a wide array of options to choose from, these systems are designed to optimize efficiency, precision, and reliability in various machining applications. In this article, we will delve into the unique benefits offered by four distinct grooving systems – Walter Cut DX, Walter Cut MX, Walter Cut GX, and Walter Cut SX – and explore how they can elevate your machining processes.

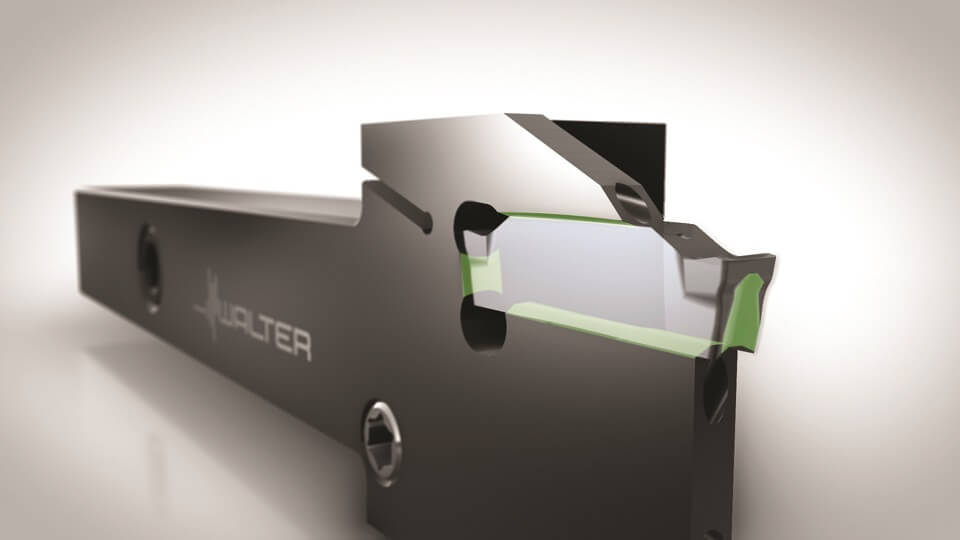

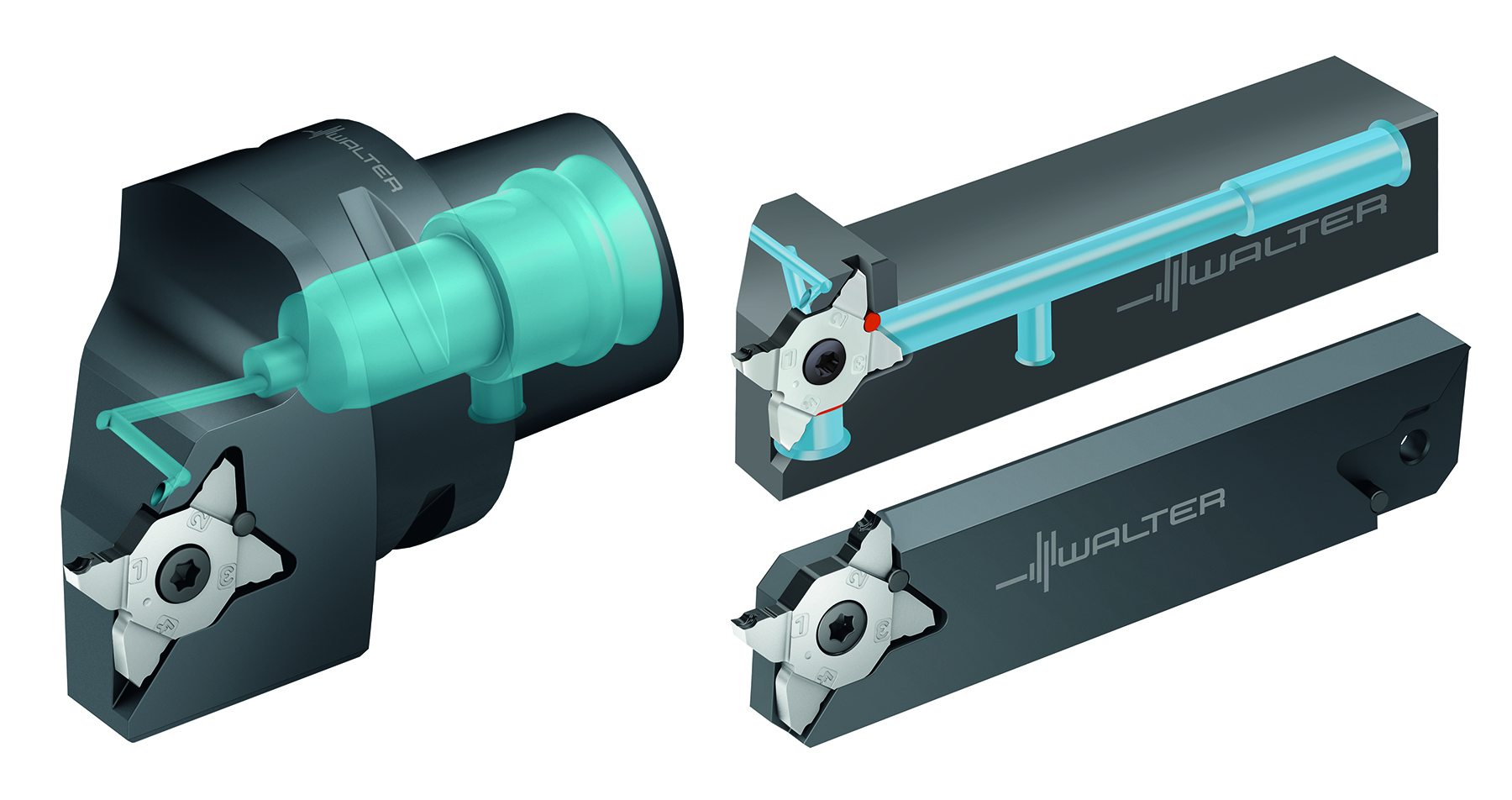

Walter Cut DX – Unparalleled Handling with “SmartLock”

When it comes to parting off diameters up to 1.378 inches (35 mm), Walter Cut DX takes the lead. This system stands out with its revolutionary “SmartLock” feature, which positions the screw connection for insert clamping on the side rather than the top. This innovation facilitates quick insert changes directly within the machine, slashing tool change time by an impressive 70%. The patented positive-locking design ensures reliability, even for small insert widths. Other key benefits include:

- Increased cutting parameters and extended tool life due to improved insert clamping stability

- Attaching cooling hoses for enhanced performance amplification

Walter Cut MX – The Cost-Efficient All-Rounder

For parting off small diameters up to 0.472 inches (12 mm) and grooving up to 0.236 inches (6 mm), Walter Cut MX is the go-to solution. This four-edged tooling system boasts exceptional versatility, making it suitable for CNC lathes, multi-spindle machines, and automatic lathes. Key features of Walter Cut MX include:

- Self-aligning tangential screw clamping for user-friendly operation

- Maximum stability and precision through a wide contact surface in the toolholder

- The flexibility to order special grooves via Walter Xpress, catering to unique needs

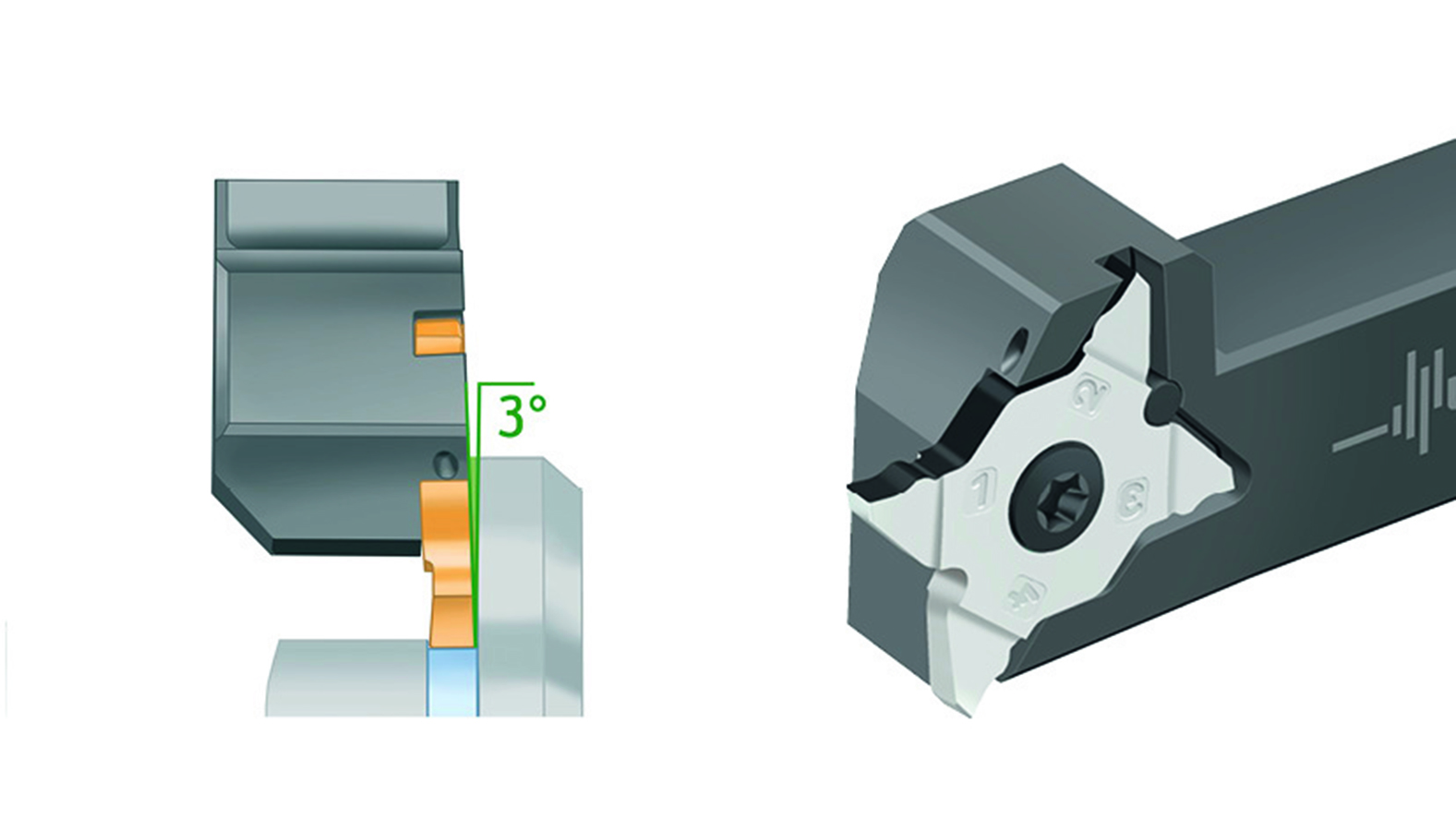

Walter Cut GX – Double the Cost-Efficiency

When you need to tackle cutting depths up to 1.299 inches (33 mm) and parting off diameters up to 2.559 inches (65 mm), Walter Cut GX is the universal choice. This system offers an array of double-edged indexable inserts in various configurations, providing remarkable flexibility. Notable benefits of Walter Cut GX include:

- A wide selection of chip formations and grades for diverse applications

- Double-edged grooving system with high cutting depths

- Capability for radial, axial, and internal machining using the same cutting inserts

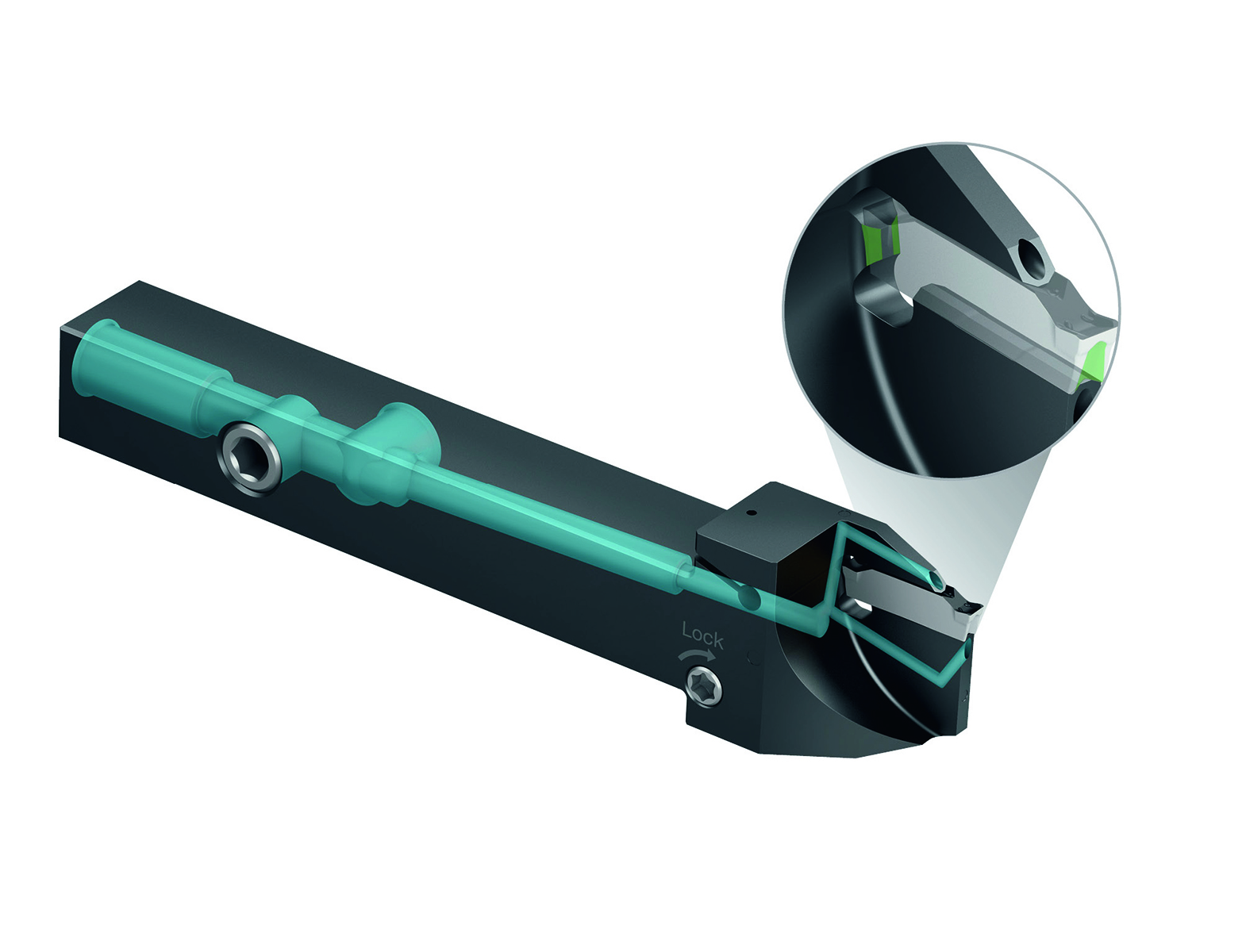

Walter Cut SX – Ideal for Large Diameters

For parting off operations involving large diameters up to 7.874 inches (200 mm), Walter Cut SX excels. This single-edged grooving system features a self-clamping design that ensures optimal insert seat stability during machining. Key advantages of Walter Cut SX include:

- No loss of cutting edge during machining due to the positive-locking self-clamping system

- Optimized chip formation options and precise coolant supply

- A single cutting insert for parting off and slitting, leading to reduced inventory costs

Your Path to Precision: The New Walter Grooving Handbook

Navigating the world of grooving operations just got easier with the new Walter Grooving Handbook. Whether you’re wondering about tool selection, chip formation, machining strategies, or material compatibility, this comprehensive guide has you covered. Download your copy today or reach out to your local Walter representative for assistance.

Experience Excellence with Walter Cut Grooving Tools

Elevate your machining results with the tailored solutions offered by Walter Cut Grooving Tools. From groove turning holders to systems for diverse grooving operations, our tools are designed to meet your specific needs. Whether you’re working with stainless steels, steels, super alloys, or other materials, our Tiger·tec® Silver grooving inserts with PVD aluminum oxide coating deliver outstanding performance.

Ready to optimize your grooving and parting off operations? Reach out to your local field sales engineer to explore the full range of benefits offered by Walter Tools Grooving Systems. Let’s embark on a journey toward enhanced efficiency, precision, and success in your machining endeavors.

Don’t forget to give this article a thumbs up and spread the word by sharing. Let’s ensure your followers, manufacturing peers, and colleagues stay informed!