New Axial Grooving System from Walter Provides a Complete Approach to Successful Axial Grooving

The Walter Cut G1111-P holder / AF5 axial grooving chip breaker system delivers strength, reliability, optimum surfaces, and high cost-efficiency.

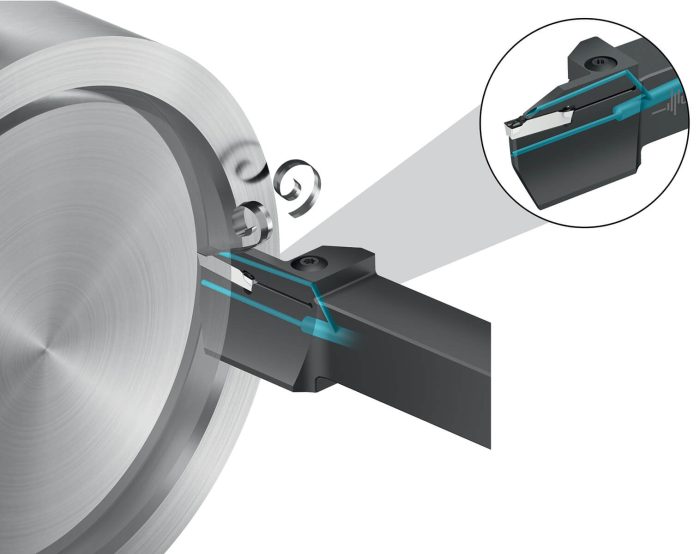

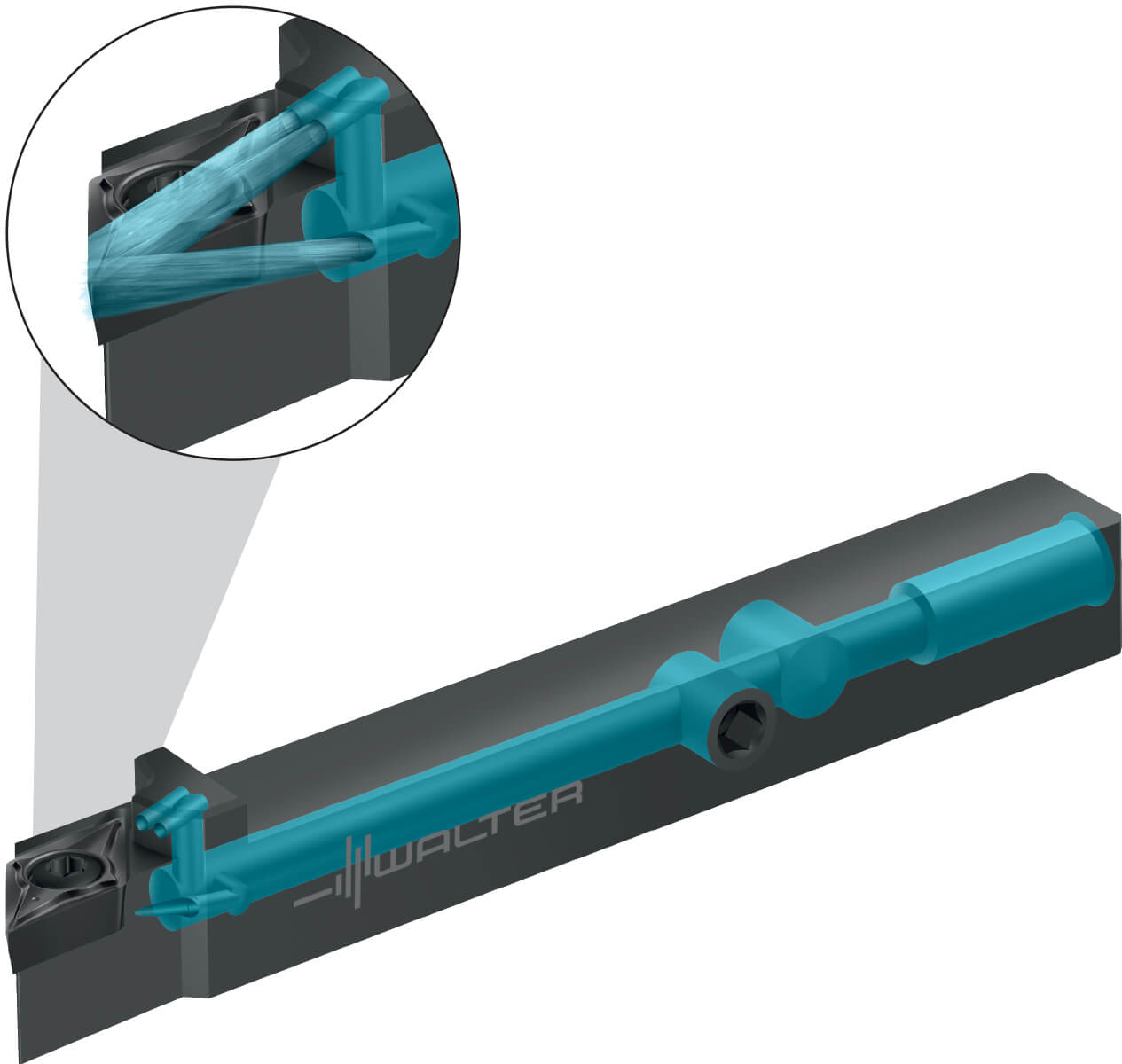

Greer, SC — Walter has introduced the Walter Cut G1111-P/GX24 AF5 axial grooving system, featuring the G1111-P GX monoblock tool for axial grooving and groove-turning with precision cooling. It provides reliability and longer insert life due to its reinforced cutting edge (e.g. with forged parts), and incorporates precision cooling on the rake face with a coolant jet aimed at the clearance face for flushing the chips out of the axial groove.

The system handles axial grooves from dia. 2.362-in (60 mm), cutting depths up to 1.299-in (33 mm), with insert width of 0.197-in (5 mm). The new system delivers maximum productivity and cutting parameters due to optimal cooling, strength and controlled chip breaking, along with high cost-efficiency due to two cutting edges. Axial grooving is effective when the groove depth is 1.5 times greater than the groove width, but to be successful axial grooving requires dedicated tooling and a dedicated chip control insert.

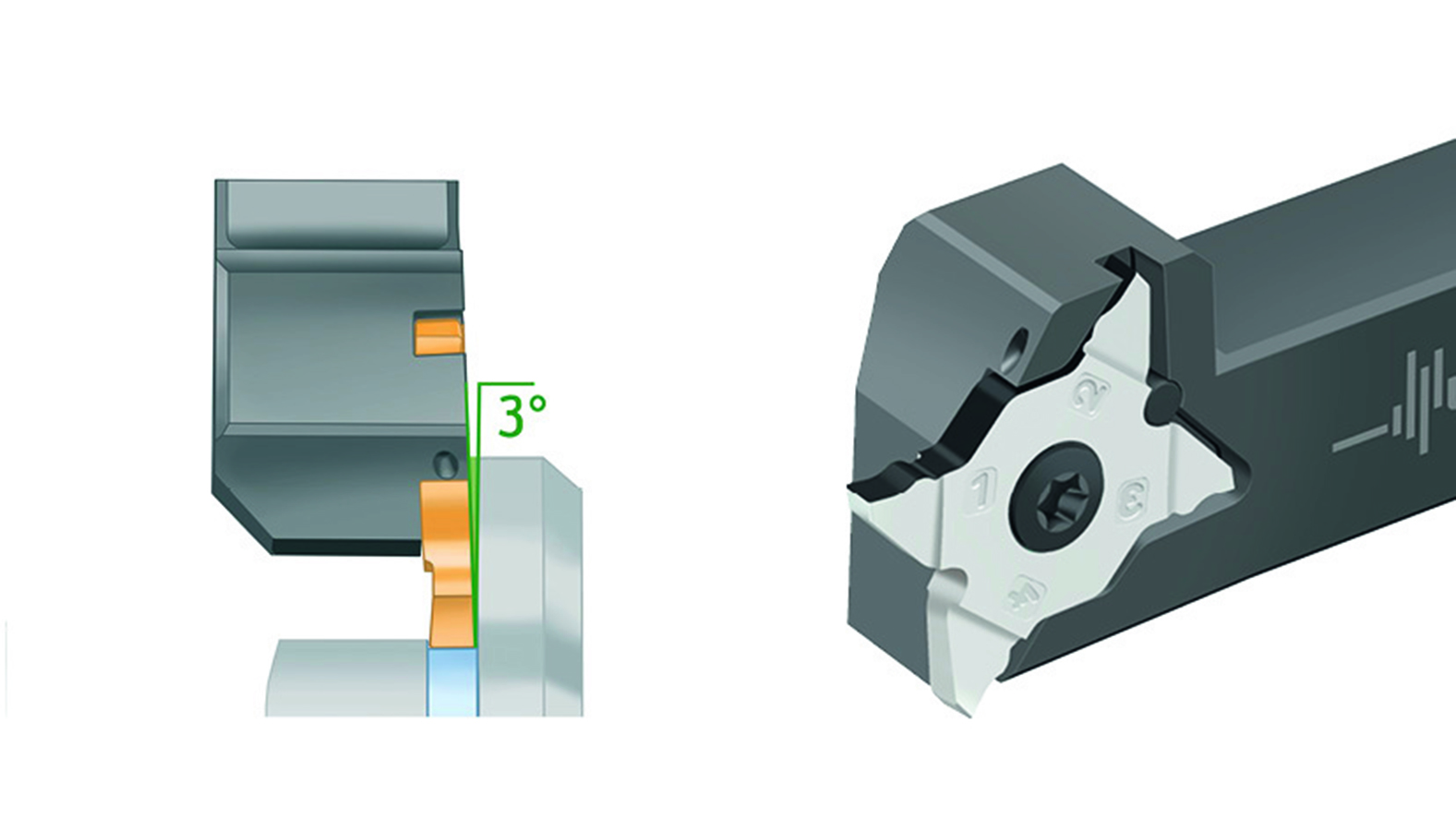

Key to the system’s success is also the new Walter Cut GX24 grooving insert with AF5 Axial chip breaker. This new right or left-handed asymmetric chip breaker takes into account the variation in cutting speed on the outside and the inside corner of the insert. The new AF5 chip breaker geometry has uneven chip breaker grooves, with shallower groove on the outside cutting corner and deeper groove towards inside cutting corner. This allows for a very efficient chip breaking operation and a smooth, scratch free finished workpiece surface. The Walter Cut G1111-P grooving holder has a diameter range of 2.362-19.685-in. (60–500 mm).

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general metalworking industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Greer, SC, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazil. www.walter-tools.com/us