New Intelligent Driven Tool Holders from WTO for Turning Centers

At the recent EMO show in Hannover, Germany, WTO presented a new generation of intelligent-driven tool holders with online process monitoring for automated turning centers and manufacturing cells: QuickFlex® smart

The aim of this new development – in line with the Industry 4.0 philosophy – is to achieve a high level of process reliability with driven tool holders in automated production cells and turning centers.

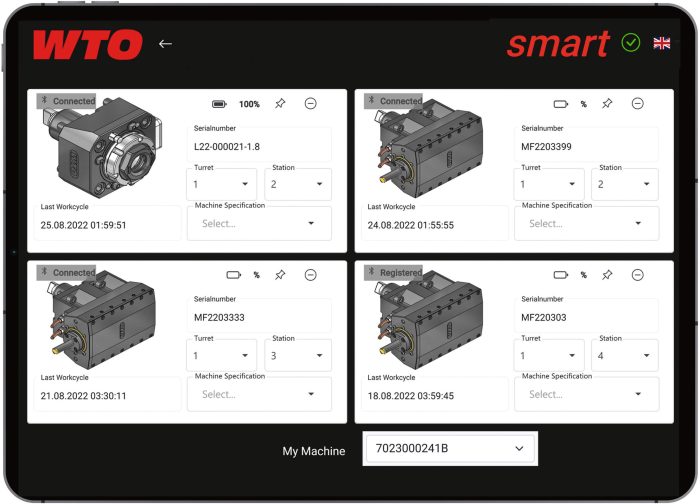

In order to ensure a high process reliability, both the cutting process and the operating status of the driven tool holder must be controlled unmanned. For this purpose, QuickFlex® smart tool holders are equipped with integrated electronic sensors for measuring speed, temperature and vibrations. The data is permanently recorded during use and transmitted wirelessly via BLE (Bluetooth Low Energy) by a built-in transmitter/receiver unit to an external gateway. A Windows PC or an iPad are useable as gateway. WTO offers suitable software for both platforms for user-friendly visualization of the data. They can be automatically stored in WTO’s myTools Cloud via the gateway. To ensure high security of the data, an encrypted data transmission with the 128 bit AES-CCM algorithm is used.

Own energy generation

The consumed electrical energy in WTO’s QuickFlex® smart tool holders is generated itself by an internal generator while the spindle is rotating. The battery is only needed during standstill to buffer the data memory in the tool holder and thus achieves a very long service life.

True online process monitoring

The data from all QuickFlex® smart tool holders is transmitted online to the gateway during operation. Using the Smart Monitor App or the myMachine App, the operator can check the quality of the process outside the machine based on the displayed information.

Tool holder condition monitoring

By permanently recording speed, temperature, vibrations and the run time during operation, the condition of a QuickFlex® smart tool holder can be monitored and the right time for the next maintenance service can be determined. Wear-related failures of driven tool holders can be avoided by preventive maintenance.

Tool holder management

WTO’s myTools Cloud is used to manage and monitor all of a company’s driven tool holders from any workstation. The statuses of the QuickFlex® smart tool holders in use can be clearly displayed via various dashboards. The data history of each tool holder can be displayed and evaluated online. myTools also enables automatic monitoring with alerting when irregularities occur in the manufacturing process or an overload occurs in operation.

Numerous advantages

With online process monitoring and automatic condition monitoring of WTO’s QuickFlex® smart tool holders, companies benefit from increased process reliability, reduced scrap rates and higher availability of their fully automated manufacturing cells.

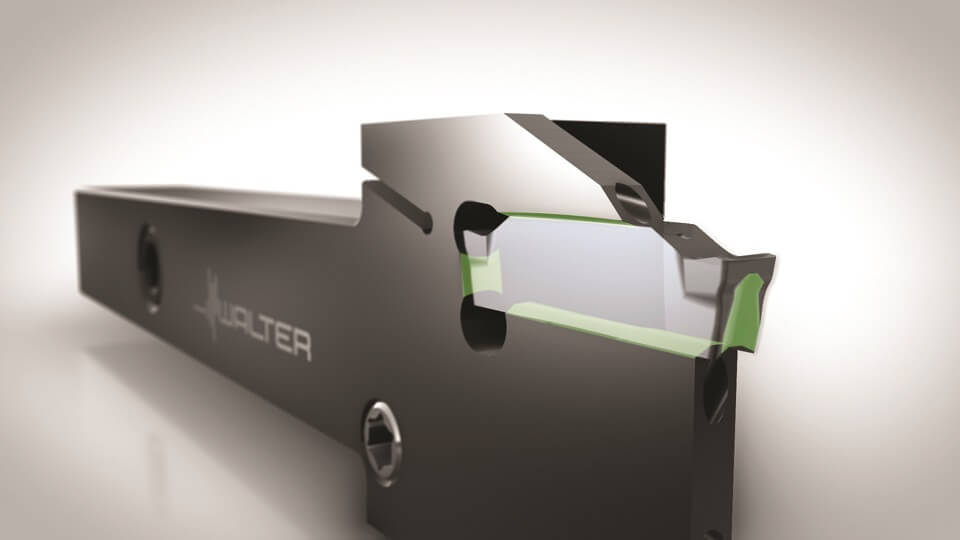

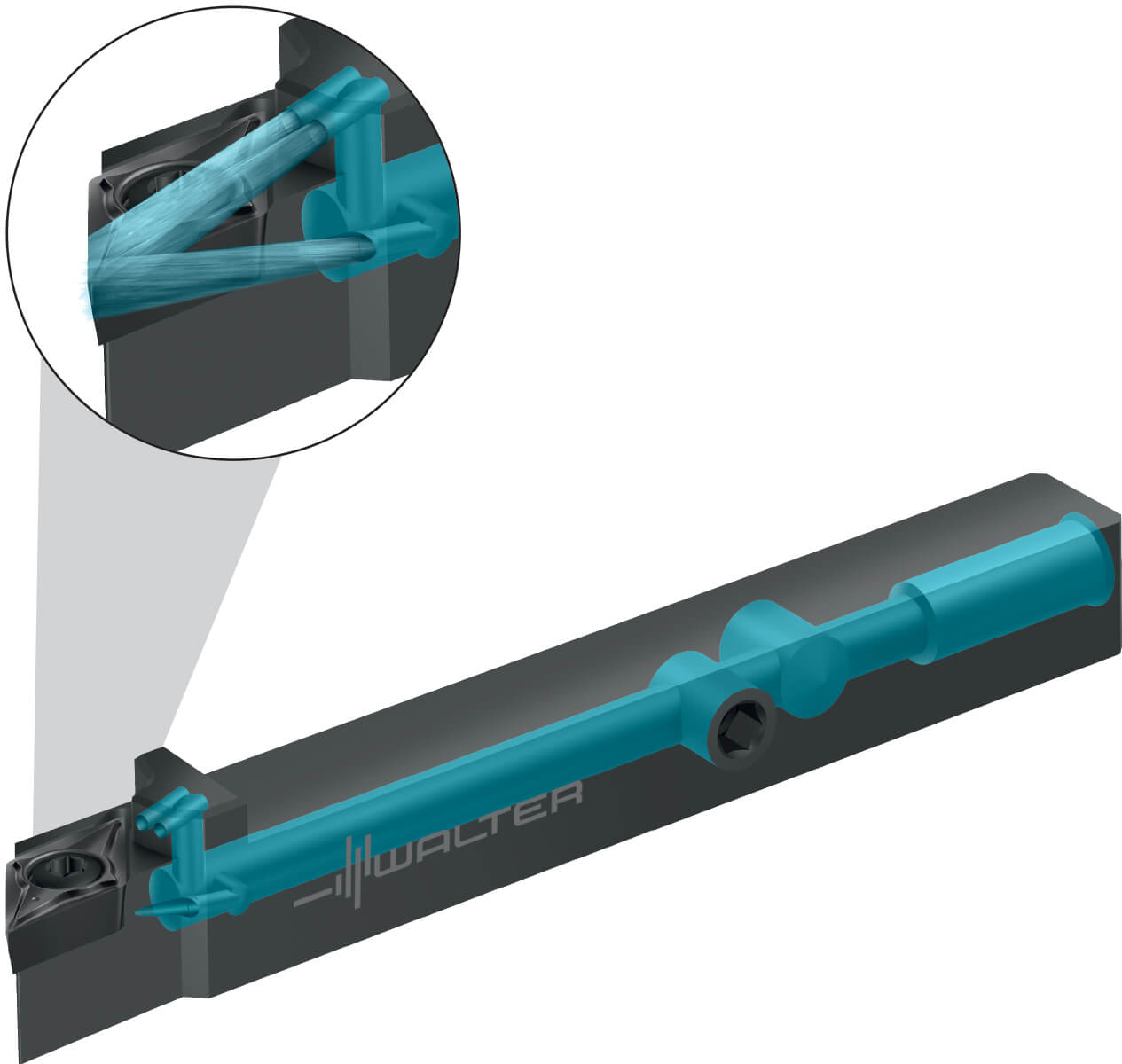

QuickFlex® quick-change system

QuickFlex® smart tool holders are mechanically equivalent to WTO’s high-quality and high-performance driven tool holders with the QuickFlex® quick-change system, which offers the user additional advantages:

Quick and safe tool change using the patented one-hand wrench

Quick change system and use of standard ER collet in one tool holder

Possibility of quick tool changes with preset cutting tools to reduce setup times