Precision Coolant Advantages For Machining Aerospace Materials

The demand for faster, cheaper and greener aerospace solutions is increasing, but building zero-emissions aircraft comes with significant challenges. While the reduction of CO2 emissions during aircraft operation has typically been the focus, the impact of material processing during manufacturing operations is equally crucial since it effects production rates, efficiency and quality control. Fortunately, applying precision coolant can help overcome these challenges to maximize output, enhance process security and improve tool performance — which also explains why the aerospace lubricants market is growing at a projected compound annual growth rate of 19 percent from 2022 to 2027.

The role of coolants in machining aerospace parts has evolved. For many years, machine shops applied coolants by directing tubes that flooded the machining zone, particularly on the materials that required coolant to be machined. But now, by applying coolant with high precision into the machining zone, new advantages are available. Broad access to this technology has been made possible with higher coolant-supply capacity CNC machines and new tooling concepts.

Making a difference

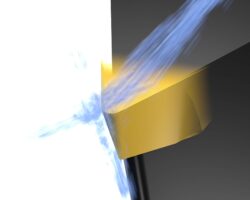

For coolant to make a difference in production, it needs to be applied as jets at high precision, in sufficient volume and with accurate direction. Relying on a stream of coolant or even flooding the machining zone with coolant is not enough. Correct application of high-precision coolant can make a distinct difference in regard to chip formation, distribution of heat, smearing of workpiece material on the cutting edge, surface integrity and tool wear. Improvements in these areas can help achieve higher competitiveness in terms of productivity, tool life, chip control and evacuation, and component quality.

When applied correctly, precision coolant maximizes output, increases process security and improves tool performance and component quality. The positive effects start at low coolant pressure, but with higher pressure, even more demanding material can successfully be machined.

While the application of precision coolant can improve machining in general – especially for stainless steel and low-carbon steel – it is when machining more demanding materials, such as heat-resistant super alloys (HRSAs) and titanium alloys, that the practice makes a dramatic difference. Fortunately, recent developments have made high-precision coolant more readily available than ever before.

High-precision coolant as standard

Many modern CNC machines have coolant supplies at pressures of 70 to 100 bar as standard or as an option with capable tanks and pumps. This is sufficient to incorporate high-precision coolant, which makes a noticeable performance difference on more commonly used machining centers, turning centers, vertical lathes and multi-task machines. Standard equipment is sufficient with easy channelling of coolant to where the jet is applied.

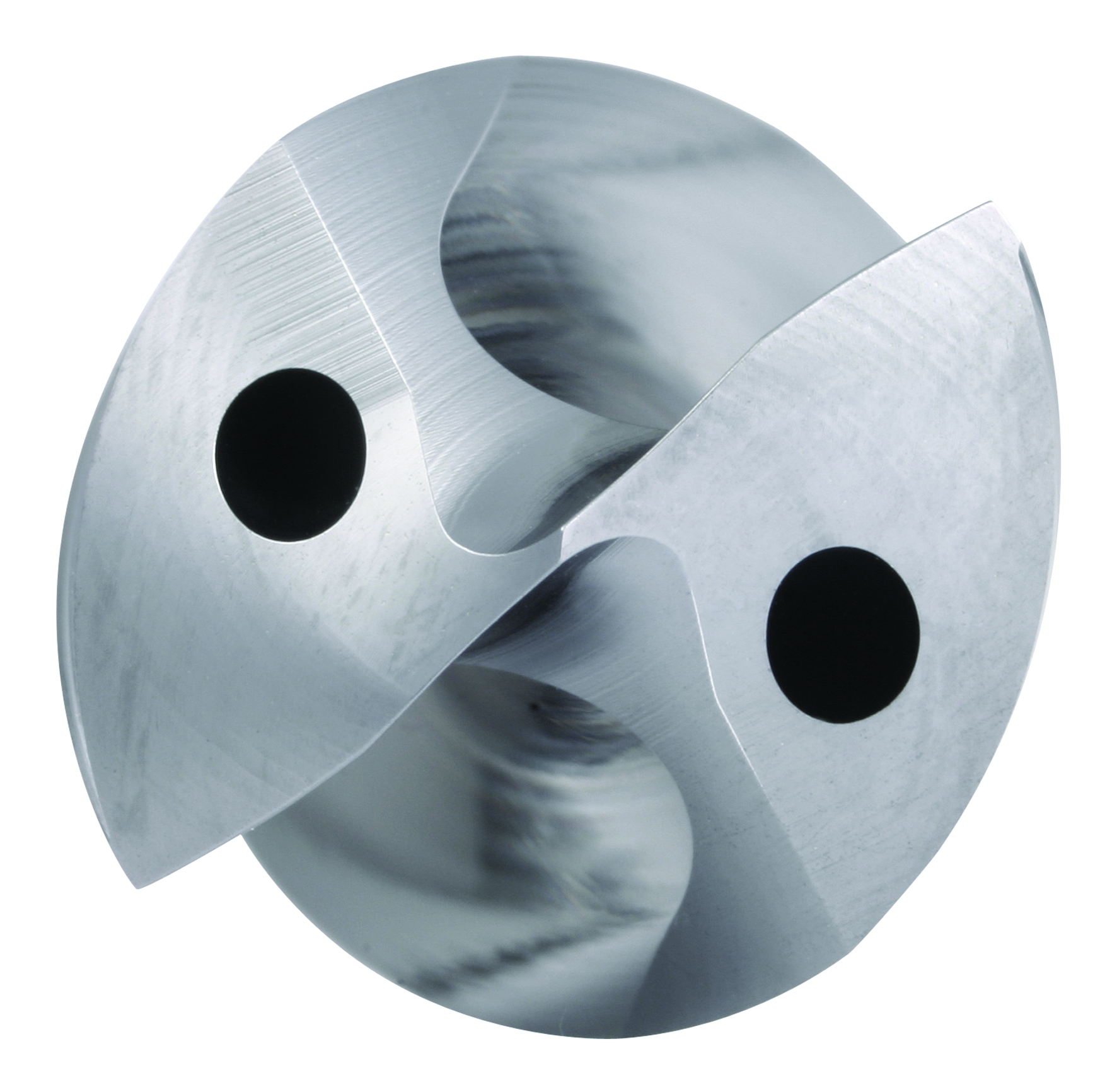

Modular tools are essential for high-precision coolant machining, partly to ensure quick tool changes for minimizing machine stoppages, but also to efficiently secure coolant connections and channels from the machine to cutting edge. Today, the modular, quick-change tooling system Coromant Capto® is fast becoming the new standard high-precision coolant tooling. This system is ideal as a modular platform, designed with internal coolant supply and well-suited to supply coolant at high precision. It adheres to established ISO standards and can be optioned on many CNC machines with stationary and rotating tools.

Precision over coolant precisely directed towards the cutting zone improves chip control and process security. Under coolant increases tool life and productivity, especially in applications generating a lot of heat in the insert.

Precision coolant for turning

Turning tools with precision coolant are equipped to give accurate coolant jets with laminar parallel flow. The jets create a hydraulic wedge between insert and chip, affecting the chip form and flow and reducing temperatures in the machining zone. Employing nozzles mounted close to the cutting edge that produce accurate, high velocity jets forces the chip off the insert face and cools and breaks the chips into smaller lengths, helping to evacuate them.

Benefits of precision cooling in finishing operations have been established even at pressures down to 10 bars in material including steel, stainless steel, aluminum, titanium and HRSAs. Apart from higher security brought about by better chip control, precision coolant can provide a considerable improvement in tool life and a potential for higher cutting speed. By applying precision coolant, 50 percent tool life increases can often be the result.

Cutting speed affects the temperature, and thus tool wear, more than any other factor. Increasing the cutting speed in titanium outside the more limited machinability window reduces tool life dramatically. But when the feed is increased on a similar scale, a smaller reduction in tool life is typical. This often makes the feed an attractive route to improved metal removal rate with low effect on tool life. However, high feed is not always an option in these machines because of higher cutting forces as well as the effect on chip control.

The effect of precision coolant can, therefore, provide the potential to raise performance by way of higher cutting speeds without the usual rise in temperature and loss in tool life. There is a clear cooling effect and not the higher cutting forces through higher feeds. For ISO S classified materials, a 20 percent increase in cutting speed can be achieved while maintaining the same cutting length.

Internal turning is also an area where precision coolant can play an important role in helping ensure good chip formation, as well as improving shearing properties in demanding materials such as titanium. This adds higher security and longer tool life to boring operations. When machining relatively large, deep holes with boring bars, such as in landing gear components, modular tooling at the back as well as the front end of the tool can be advantageous.

Being able to change the small cutting head on the clamped bar provides quick, easy and accurate changing, adding considerable flexibility for various cuts in one set-up. CoroTurn® SL combines damped boring bars with serrated locking of heads for boring larger holes with depths of 10 times the diameter and is also equipped with precision coolant facilities.

Variation in component surface integrity is affected by the temperature and forces generated during machining. Coolant certainly plays its part in controlling the temperature and, as a result, precision coolant has been shown to provide a more reliable surface result. Tool nozzles are aimed directly at the part of the insert in contact with the finished surface. Since the nozzles are non-adjustable, many variables are eliminated, resulting in a more secure and consistent machining process.

Optimization of correctly established operations

With the ability to force a fluid wedge into the machining zone, especially in operations classified as medium to finish turning, the chip thickness is more controllable and the fluid wedge easier to apply than in roughing operations.

The application of high-precision coolant machining should not be seen as a means with which to compensate shortcomings due to other application factors – such as unsuitable inserts, instability or incorrect cutting data. Precision coolant is an optimizer when operations are correctly established, providing the means for shorter cycle times, improved component quality consistency, and higher process security in turning and milling.