Reamer Reconditioning Service Delivers Lower Cost-Per-Unit

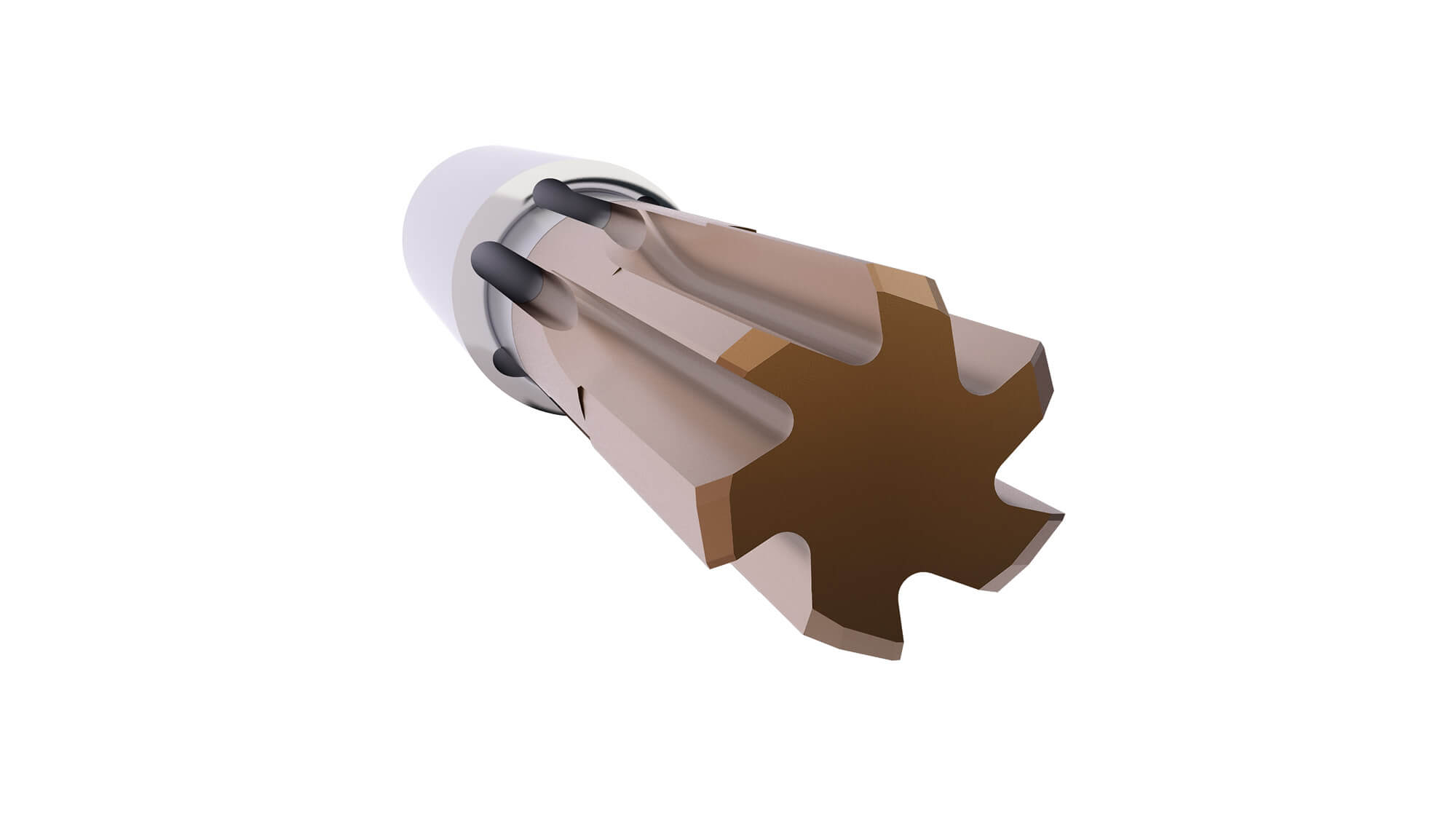

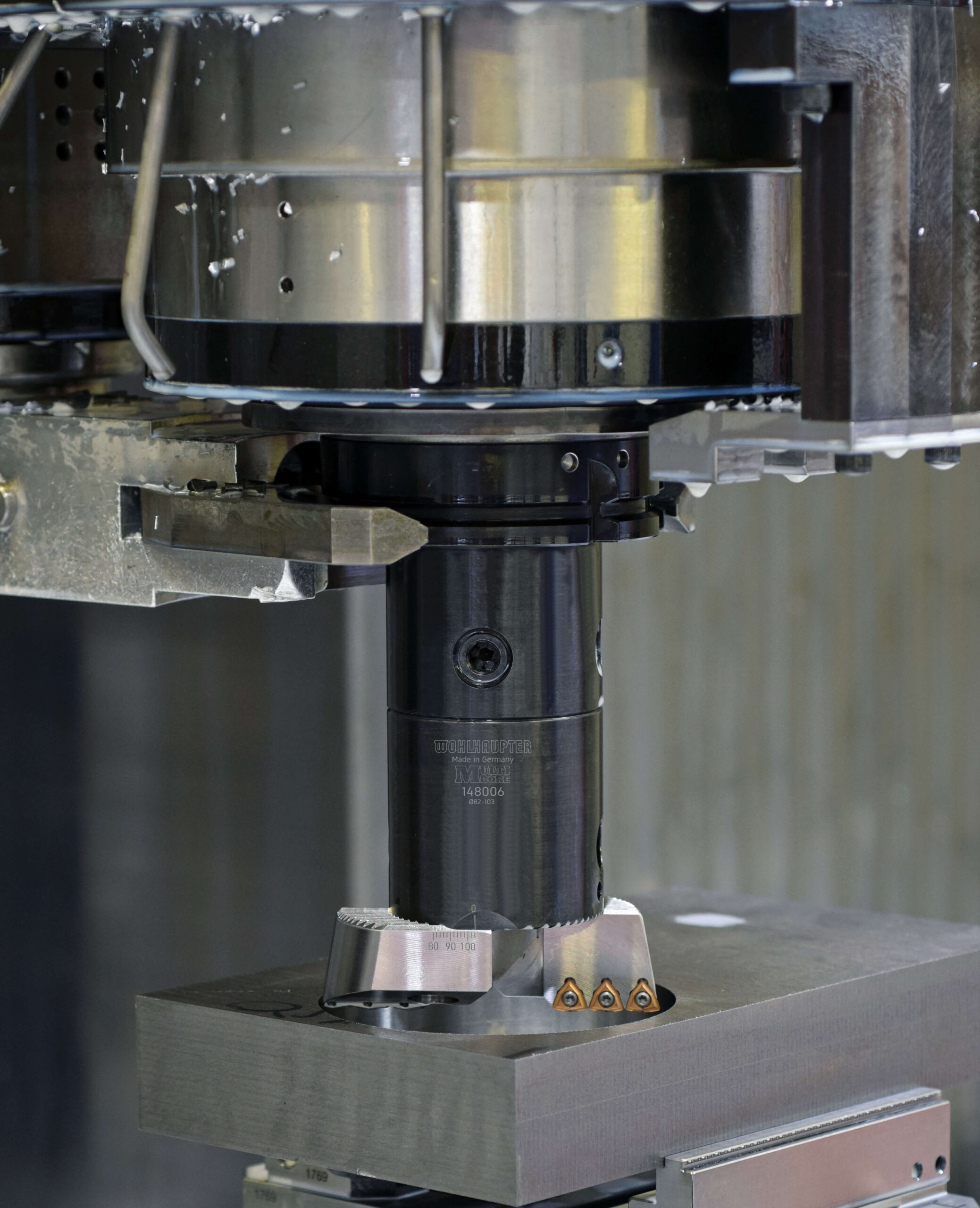

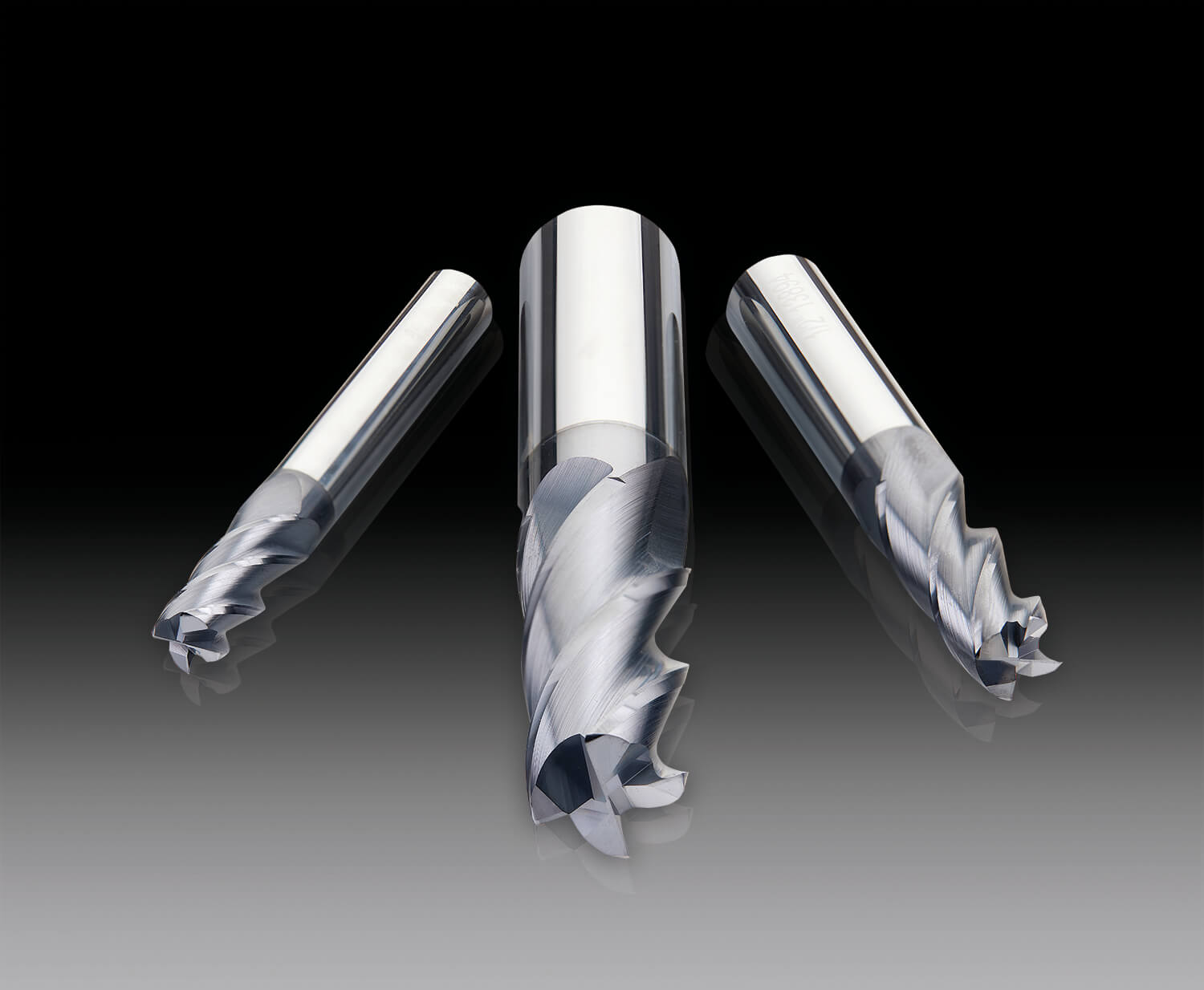

Dayton, OH — Diatool offers a Reamer Reconditioning Service which can retip, renew, and restore most major brands of high-performance reamers to OEM specs. This unique service includes replacing all blades, grinding a fresh bevel geometry, refurbishing the body of the reamer, and coating of the blades if required. Diatool Reamer Reconditioning is ideal for solid and expandable monoblock reamers, expandable cutting rings, and replaceable head reamers. Diatool can provide multiple options in advanced coatings and blade materials using cermet, coated carbide or PCD. Unlike some major competitors, Diatool does not limit the times a reamer can be reconditioned, providing an even longer service life of the reamer with no compromise in tool life or cutting quality. Offering standard deliveries of 4-6 weeks and cost savings of 40 percent over new, Diatool’s Reamer Reconditioning Service is ideal for machining operations struggling with long lead-times or non-responsive tooling vendors.

In addition to refurbishing, Diatool offers application consultation to improve existing tooling by offering the latest alternative geometries or coatings. Typical results are higher bore quality of the part, reduced cycle time, and significant CPU savings without reinvestment in new tooling.

Diatool has over 35 years’ experience in building and reconditioning of high performance reaming systems. They have become the industry leader in high performance reaming by providing application driven solutions and offering superior quality reaming products.

For additional information on Monaghan’s Diatool Reamer Reconditioning service visit https://monaghantooling.com/