How Cobots Transform the Metal and Machining Industry

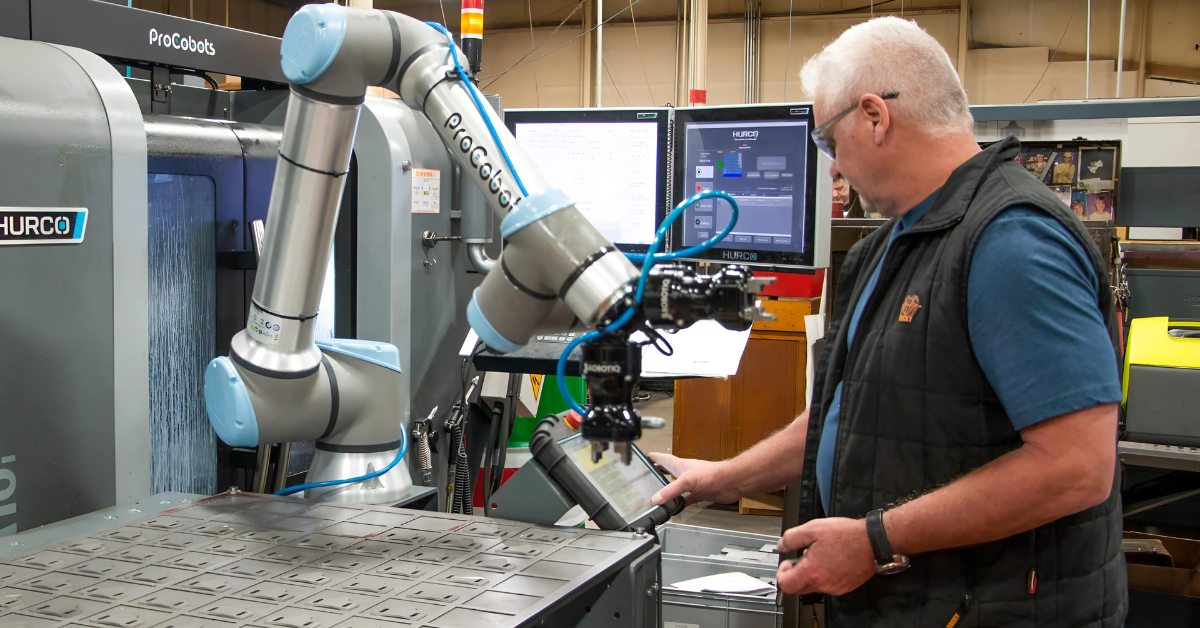

If your equipment is idle, it costs you money. Machine tending roles often pose challenges in recruitment and retention, yet cobots offer a constant workforce. Collaborative automation, particularly suited for tasks like CNC and die cast machines, press brakes, and dial tables, ensures consistent and reliable operation around the clock. This enables the seamless transition of skilled machinists to more valuable positions, maintaining shop productivity.

Cobots are also at the heart of collaborative welding systems that cost a fraction of traditional automated systems and can fit into standard welding work cells. Automate repetitive or small products that are undesirable for welders and move your best welders to high-profit product lines – leading to improved quality consistency and higher worker satisfaction.

Download this expert guide to:

- Discover cobots’ basics, design and distinguishing features compared to conventional industrial robots

- Explore specific applications and case studies showcasing cobots’ effectiveness in metal and machining industries

- Understand how cobots contribute to heightened precision, efficiency and adaptability in production processes

SPONSORED BY

DOWNLOAD NOW

Fill out the form below to receive

FREE access to this guide