Riding the Shoulder

SPONSORED CONTENT

How to improve tool life and increase productivity during helical milling operations

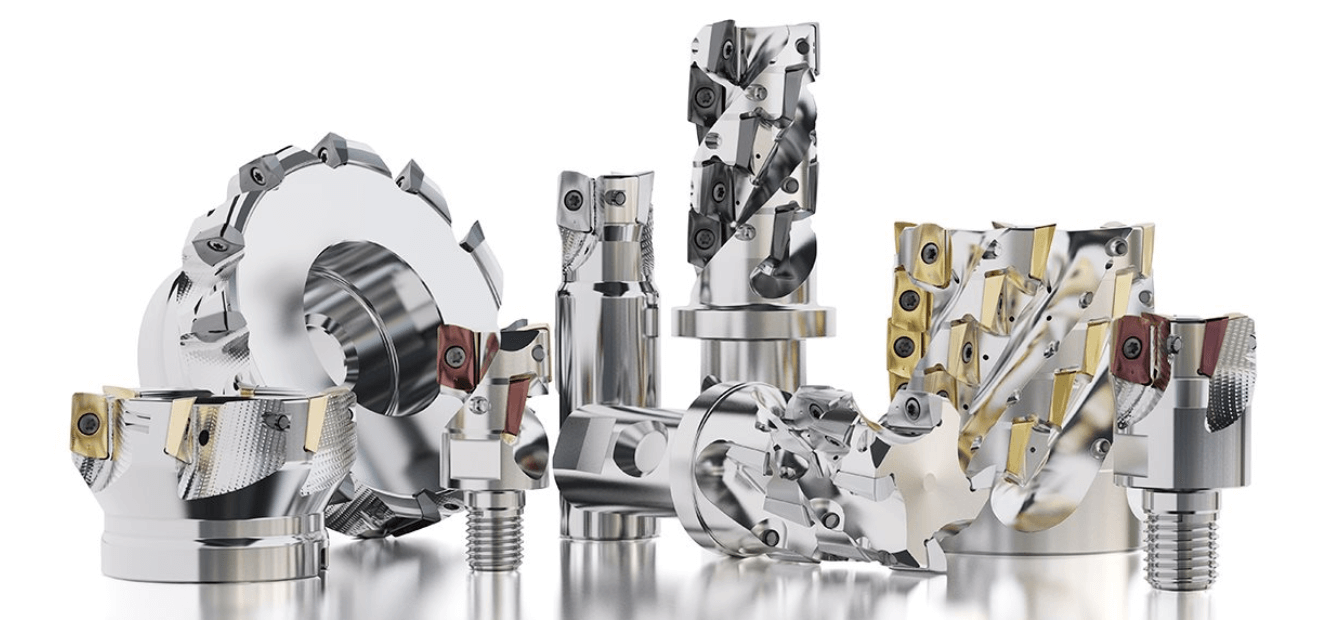

Where would the machining world be without helical milling cutters? They’re used to square off the ends of parts, mill pockets and cut profiles, and are especially useful for producing square shoulders on parts of all sizes. Machinists have long used solid carbide or high-speed steel (HSS) end mills for these tasks, but carbide versions of these tools are limited to around 1-inch (25 mm) in diameter and are quite expensive in that size range to boot. And while HSS end mills up to 2-1/2-inches (75 mm) or so are available, high-speed steel is anything but high speed. Given the constant pressure for lower tooling costs and increased productivity, this explains why many shops have turned to indexable tooling for their large diameter helical milling operations.

Unlike humans, however, not all milling cutters are created equal. For years, indexable end mills have suffered a host of problems ranging from insert movement within the pocket to chips jamming in the flutes, both of which can lead to catastrophic failure. Compounding this are chatter, poor tool life, and less than optimal metal removal rates, especially when milling stainless steels and superalloys such as titanium, 17-4 PH, and everyone’s favorite, Inconel.

Meeting the challenge

Fortunately, a number of high-quality milling solutions have hit the shop floor of late, partly in response to a well-known aerospace manufacturer’s calls for greater productivity when machining titanium. These “Industry Challenges” have helped cutting tool providers fine-tune their existing products and develop completely new ones, and pushed the limits of what’s possible when machining this and other HRSA (heat-resistant superalloy) materials.

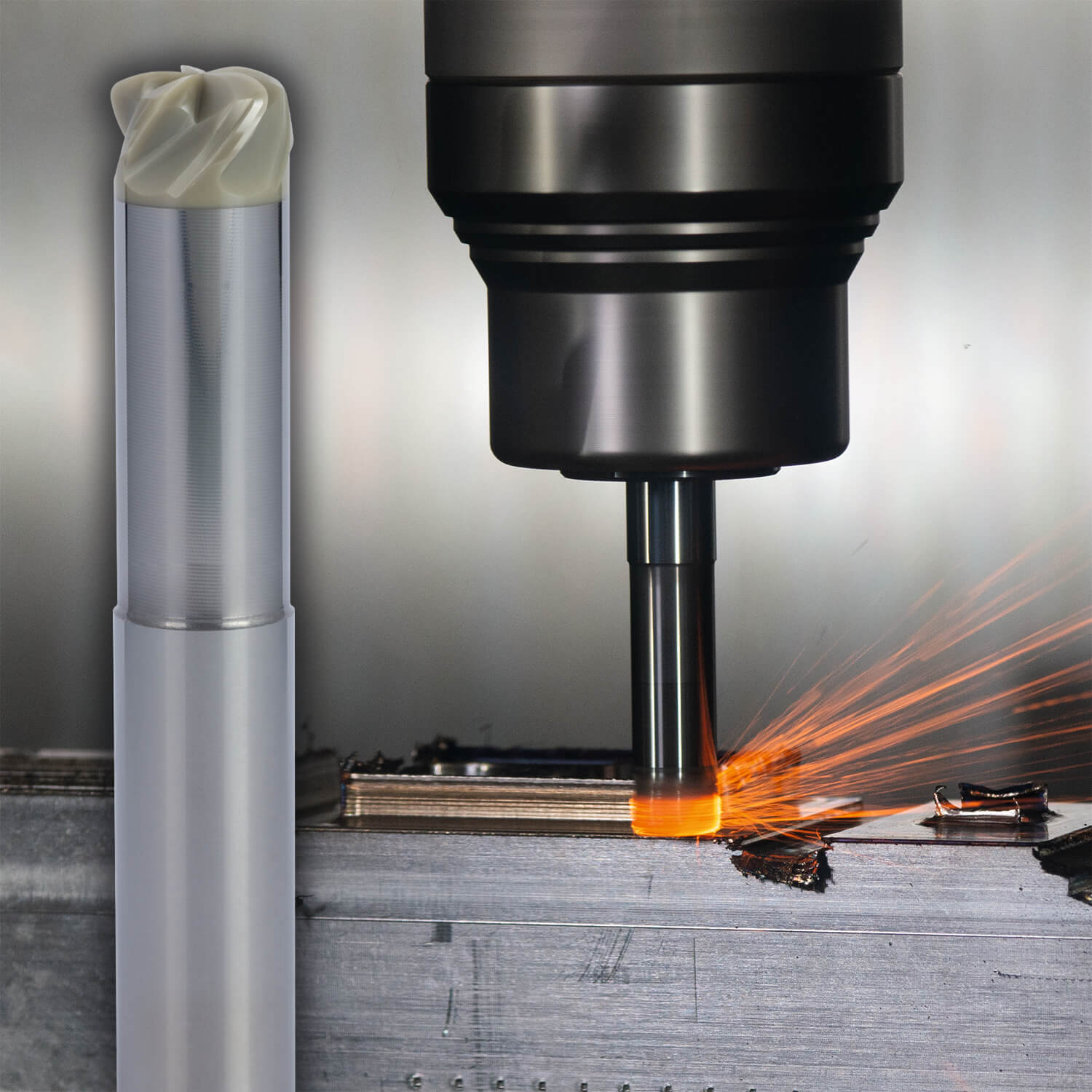

The test goals were straightforward: remove 20 cubic inches of titanium grade Ti-6Al4V per minute for one hour while achieving tool life at least as good as the company’s legacy solution. All of the major cutting tool suppliers and many smaller ones participated, and even though Kennametal was meeting the requirements set by the challenge, its engineers went back to the drawing board and developed what’s now known as HARVI Ultra 8X.

A helical milling cutter that actually achieved three times the original metal removal goals, or 61 in3/min (1000 cm3/min) per hour. What’s more, cutting forces were reduced by 15 to 20-percent on average, edge wear was both consistent and predictable, and the inserts lasted 92 minutes before being deemed unusable.

When shopping for your next helical shoulder milling cutter, look for one with generous coolant flow through the tool and chip gullets deep enough to prevent packing

Horn tooting aside, the point here is that everyone wins when manufacturers engage in a fair competition, especially the people who use these cutting tools on a daily basis: machinists. But what’s changed with this next generation of indexable milling cutters? And how is a machinist to know what to look for in a helical milling cutter, short of launching his or her own industry challenge?

Taking the challenge

Actually, asking your cutting tool suppliers to participate periodically in formalized and well-documented tests such as this is a great way to keep abreast on the latest technology, regardless of the time and expense that goes into such comparisons. Until then, however, consider the following attributes of a winning milling cutter:

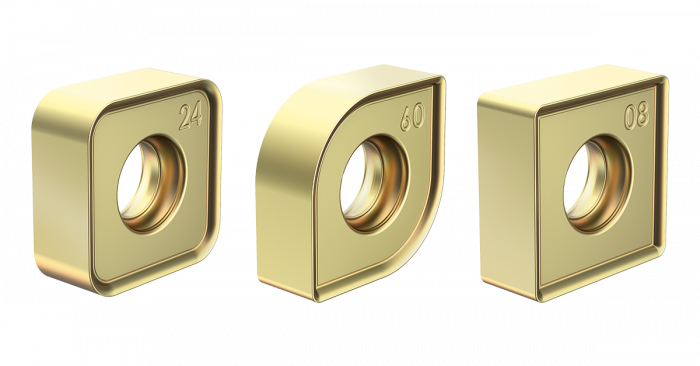

Edges per insert

If carbide was dirt cheap, there’d be no reason for articles like this one because everyone would simply use solid carbide tools, regardless of their size. Sadly, that’s not the case, which is why shops everywhere are looking for ways to reduce their tooling costs, and the best way to do that is to increase the number of edges per insert; where most styles of indexable helical milling cutters offer only four today, the HARVI Ultra 8X has eight cutting edges per insert. Effectively cutting the cost per edge in half. In addition, its inserts are available with a broad selection of corner radii, so that the cutting action can be fine-tuned according to where the insert sits in the holder—you might want to use 0.250 in. (6.4 mm) radius inserts on the end of the tool, for example, and ones with a 0.031 in. (0.8 mm) radius higher up in the cutter body.

The only one. HARVI Ultra 8X is the only indexable helical milling cutter platform that offers 8 cutting edges per insert.

Positive cutting action

I know what you’re thinking—it’s easy to create additional cutting edges when you use a double-sided insert, and as anyone who’s used one knows, double-sided has long meant a negative rake and therefore high cutting forces. Not anymore. Thanks to some cleverly designed cutter bodies and advanced carbide manufacturing techniques, it’s now possible to achieve free-cutting, positive rake geometries suitable for the materials that need them most—titanium and aerospace alloys that are high in nickel and chrome.

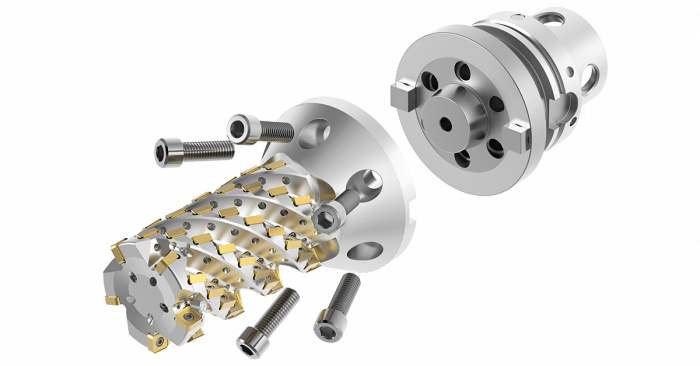

Better pockets

Lower cost per edge is meaningless if the insert shifts in the pocket during cutting, damaging the cutter body and quite possibly scrapping a very expensive workpiece. Fortunately, the same clever designs that make today’s indexable end mills freer cutting also make the inserts extremely secure. Just be sure to look for an equally secure locking mechanism, preferably one that uses M4 or larger Torx Plus screws for maximum clamping power.

Grades and coatings

What good is a robust cutter body without robust carbide to match? If you haven’t kicked the tires on indexable inserts lately, now’s a good time to do so, even if you’re not looking for a new milling solution. Carbide technology has improved greatly over recent years, as have the available coatings. The result is that carbide has achieved the Goldilocks zone of wear-resistance and toughness, with multi-phase coatings that provide extreme resistance to thermal fatigue, one of the primary culprits behind cutter failure during milling operations.

Keeping cool

This last attribute is more about machine tool technology than it is about cutter bodies or carbide. Through-the-tool cutting fluid—often applied at pressures of 1000 psi (80 bar) or greater—is changing the way shops make parts, and in response, the way that cutting tool manufacturers make cutting tools. Look for indexable tools with plenty of plumbing options, so that coolant can be directed where it’s needed most. No more hoses, no more chip-jammed gullets or the crunch, crunch, crunch of recutting, just a generous flow of cutting fluid, higher feedrates, and tool life that will pleasantly surprise you.

There’s more. A high-performance helical milling cutter should be made of high-strength steel for ultimate stiffness and rigidity. The gullets should be deep enough to efficiently evacuate chips without sacrificing body strength. It should have a spindle interface that compliments this construction, which in the case of the Industry Challenge mentioned earlier was the newly redesigned KM4X quick-change system. And the body mount must be equally rigid, preferably one with a bending moment greater than traditional shell mill type holders but with the versatility to connect to multiple spindle types.

Kennametal’s HARVI Ultra8X is available with a BTF 46 (Bolt Taper Flange) mounting interface that’s nearly as rigid as a one-piece construction, outperforming conventional shell mill mounts by far. With a KM4X connection more rigidity is being added, as well as higher bending moment.

The happy ending

Add it all up and you’re looking at a 2 to 3-inch diameter helical end mill able to hog titanium and other difficult materials at 200 SFM or higher, using a 25 to 30-percent radial depth of cut and taking axial cuts up to 9 inches deep, depending on the size of the cutter, the workpiece, and the rigidity of the machine and setup. Best of all, these inserts in these cutters last longer than anything offered thus far. The cost per edge is lower, processes are more predictable, and more parts go out the door each day. If you machine large aerospace parts, mold cavities, or power and energy components, you owe it to yourself to take a look

LEARN MORE ABOUT THE HARVI Ultra 8X

Author: Tim Marshall, Product Manager for Indexable Milling at Kennametal Inc., Latrobe, Pennsylvania