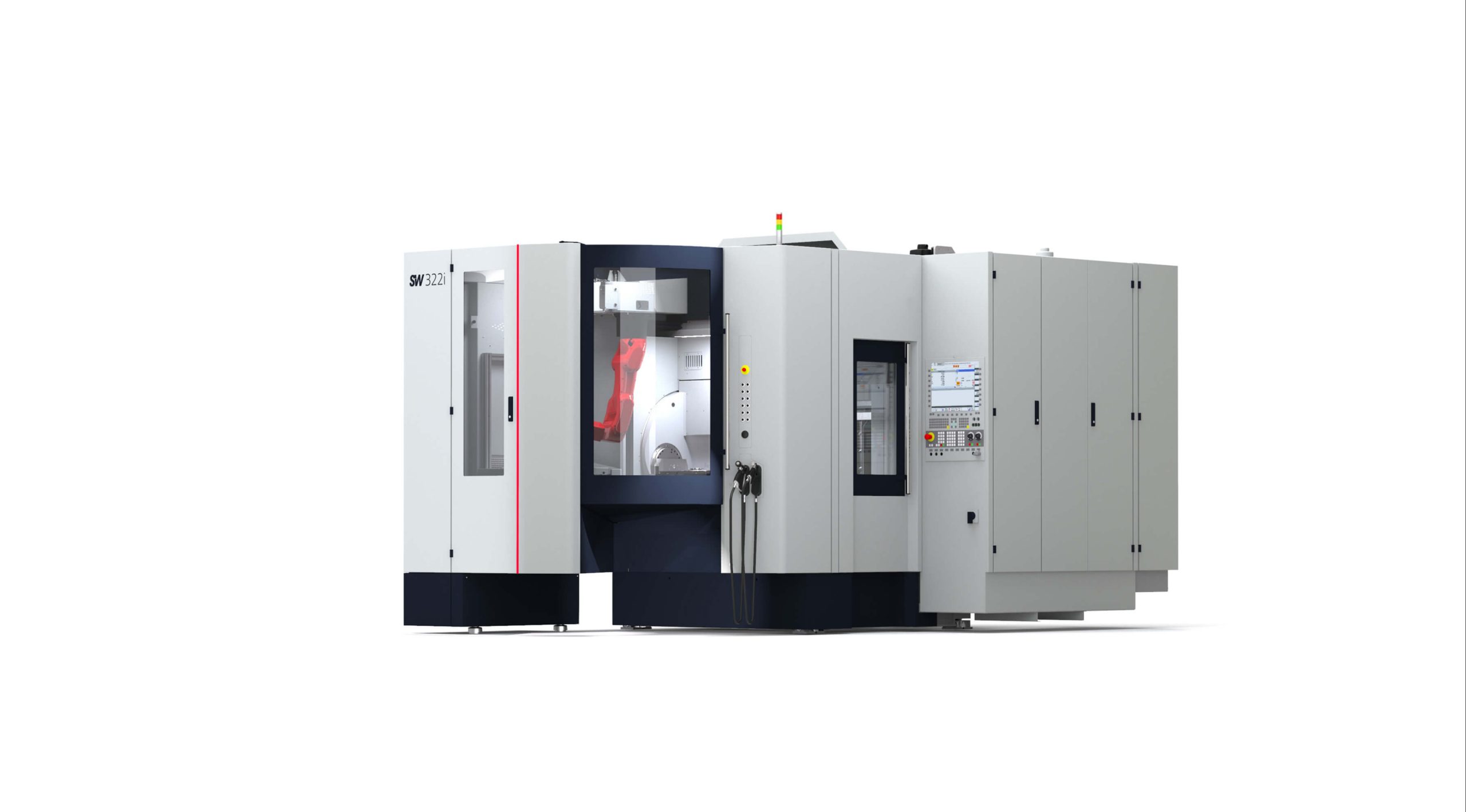

All About SW’s BA 322i Independent Manufacturing Cell

New Hudson, Michigan – Schwäbische Werkzeugmaschinen’s (SW) BA 322i is designed to function as an independent manufacturing cell that can store enough workpieces for an entire shift. This twin-spindle horizontal machining center produces twice the output while using less floor space and less energy. The BA W02 and BA 3 series are available with a loading module with an integrated 6-axis robot and vertical workpiece storage. SW’s double swivel carrier enables loading and unloading in parallel to machining time. The vertical workpiece storage is conveniently located to the side and has been trimmed down to require minimal space. The new BA 3 series features the monobloc design in combination with the box-in-box 3-axis unit, double swivel carrier and 1, 2 or 4 horizontal spindles with 300 mm spindle distance.

SW’s BA 322i is a twin-spindle horizontal machining center that functions as an independent manufacturing cell capable of twice the output with less floor space and energy consumption.

The new BA space3 was built with the EV market in mind. With an impressive working range of 3,000 x 1,800 x 875 mm on the X-, Y- and Z-axes, it can easily accommodate large, light metal structural components. The machine is available in two base variants – a 5-axis machining center with a two-axis swivel head, or a three-axis version with rigid spindle. The 2-axis swivel head variant enables machining from all angles while the rigid spindle version allows for straightforward correction in all axes for high flexibility and quality. The tool magazine for the BA space3 is a chain design with a capacity of 40 or 80 tools. There are linear drives in all feed axes, meaning that not only can the BA space3 machine large workpieces, but it does so quickly. The C|one Control Panel is a multi-touch display that introduces Industry 4.0 seamlessly into your production line and creates a seamless user experience. SW Core software comes integrated and access is authorized via microchip.

SW North America, Inc. is a world class supplier of turnkey manufacturing solutions including multi-spindle horizontal CNC machining centers with advanced automation concepts. The multi-spindle machining centers from SW enable highly efficient and precise production of components across many industries. As a system partner we also plan complete manufacturing lines for you and set them up with automation perfectly tailored to your components – all from a single provider.

SW North America is a subsidiary of Schwäbische Werkzeugmaschinen GmbH. SW currently has 1000 employees worldwide. In addition to SW Automation in Tettnang, Germany, which specializes in automation, SW also has subsidiaries in France, Italy and Poland as well as in the USA, in China and in Mexico.

Address

SW North America, 30160 Lyon Industrial Court, New Hudson, MI 48165, T.: +1 248-617-3800, contact.na@sw-machines.com, www.sw-machines.com

Editorial Contact: Jennifer Brozek, Marketing Manager

Email: Jennifer.Brozek@sw-machines.com

Phone: 248-878-7862

Sales Contact: Andrew Rowley, General Sales Manager

Email: Andrew.Rowley@sw-machines.com

Phone: 330-298-8295