Take Your Milling Knowledge to the Next Level

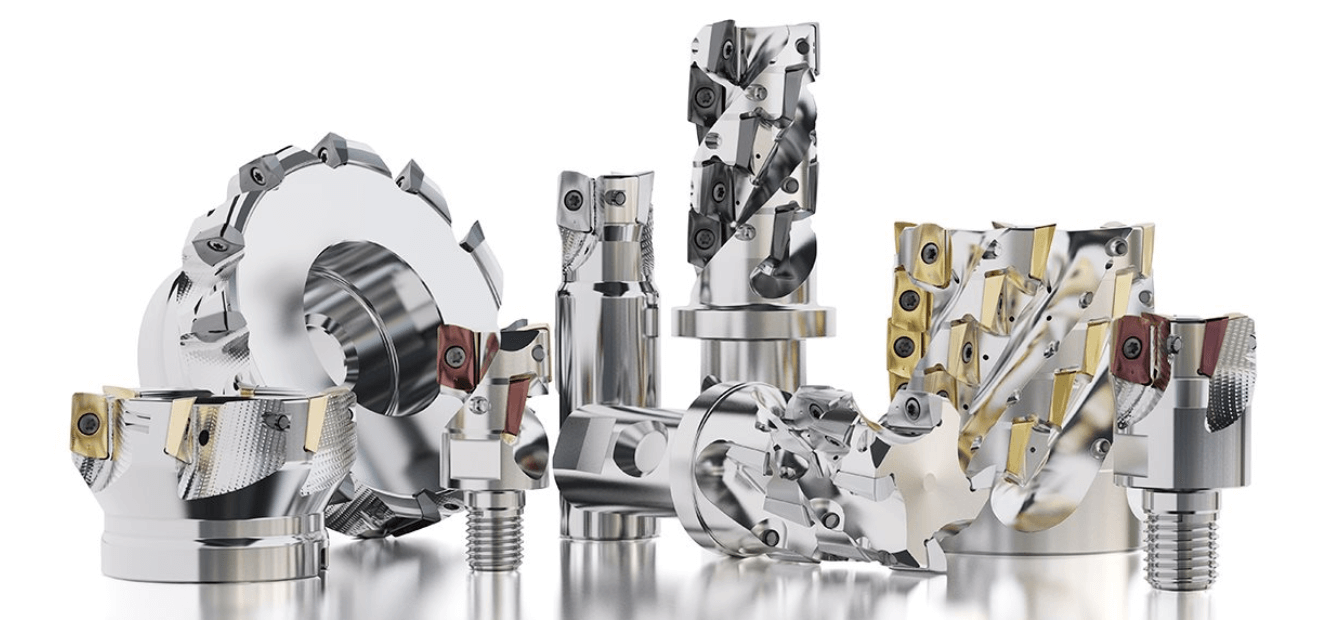

Milling machines are famous for their versatility. Although most used to machine flat surfaces, these machines can also produce irregular surfaces, drill, bore, cut gears, and produce slots. In simple terms milling uses cutters to cut through the material of the work-piece surface and can support a wide variety of operations from large to small projects. Milling is one of the most common machining processes and can achieve some of the most precise tolerances.

The two main types of milling are face milling and peripheral milling. In face milling, the cutting action takes place at the end corners of the cutter and is most used to cut flat surfaces, or faces, into the work piece. On some occasions, face milling is used to cut flat-bottomed cavities. In peripheral milling, the cutting action occurs along the circumference off the cutter. This style of milling is best for cutting deep slots, threads, and gear teeth.

The flexibility of these machines is not only explained by their capabilities like carving, threading, milling, drilling, and cutting, but also by the myriad of milling machine types and their associated functions. For example, different milling machines are named by their kind of control, number of axes, spindle orientation, tool size, purpose, power, and more.

Recommended Milling Books

If you’re hoping to master your milling machine, it is important to thoroughly read the manual, as manuals are a prime source of information to truly understand your machine. However, if you are looking to take your milling knowledge to the next level, here are 6 books we recommend.

High–Speed, Hard-Milling Solutions

In addition to highlighting machine tools and their associated characteristics, this text includes learnings about critical support technologies for the machine and its processes. This book focuses on what technologies to invest in and which to avoid to maximize the results of your high-speed, hard milling applications.

CNC Milling in the Workshop

This guide is focused on helping machinists implement a practical approach to milling software and techniques. With authoritative industry advice, you will learn how to make complete and full use of your milling machine for optimal programming and CNC mill operations.

Milling Machine Kinks

As a machinist, you will appreciate this classic that covers (in thorough detail) pretty much all milling topics including: feeds and speeds, dials for jig hole locating on the miller, different high-speed milling attachments and more.

A Treatise on Milling and Milling Machines

A classic writing by the Cincinnati Milling Machine Company of 1919, this book notes the evolution of milling, as the milling machine and milling process has developed drastically over time. You will learn the construction and use of milling machines along with the care and adjustment of milling machines. The perfect read for toolroom millers.

Machinery’s Handbook, Toolbox Edition

This handbook is a staple for every machinist. Although not completely focused on milling, this text is commonly referred to as the “Bible of the Metalworking Industries” so we, among many other metalworking professionals, consider it an essential reference. The 30th edition features an expanded section on metrology, shaft alignment and so much more.

Milling Machines & Milling Operations-Second Edition: The Fundamentals of Conventional and CNC Milling

If your key learning objectives include cutting mechanics, types of milling operations and machines, and methods of controlling temperature, do not miss out on this read. As the second edition, this book dives deep into CNC milling technology with lectures explaining the advantages of these machines in comparison to other conventional machines. This book is loaded with information to help you optimize every aspect of your milling process, from production times and conversational/CAM programming to measurement and gauging, and so much more.

This post may contain affiliate links. Please read our disclosure for more info.

4 Comments

Are all of these books necessary? They are very expensive. Are there a few books I could purchase that encompasses all of maching techniques? As of now this site recommended 12 books in the last two days. That is nearly $1000 in books that probably overlap one another as far as information. What are the ABSOLUTE essential books I need to purchase without going broke doing it? I already wasted $10,000 on an Advanced Manufacturing Te hnology course at a local community college that was a complete joke!!!!!!!!!

They need to produce a simple low-cost book that helps the home machinest on how to set up the work pieces with clamps and certain positions the work piece needs to be.

Spend a few hours a week watching mrpete222 (older videos especially), abom79, and vintagemachinery youtube channels and then practice what you learn. There are a host of other excellent channels and together you will get 101% of what books can typically offer AND show you real world examples of what to do and importantly what NOT to do. Safety is, of course, the first priority. You can download some of the old school books like South Bend’s “How to Run a Lathe” from various sources. These cover basics that never change like tool shapes, work holding, and cutting directions. If you are totally in to CNC, then you have a different problem and best to get specific training from the machine manufacturers.

One of the finest references I have ever seen