The Tools That Make Pockets in Titanium for Aerospace and Beyond

SPONSORED CONTENT

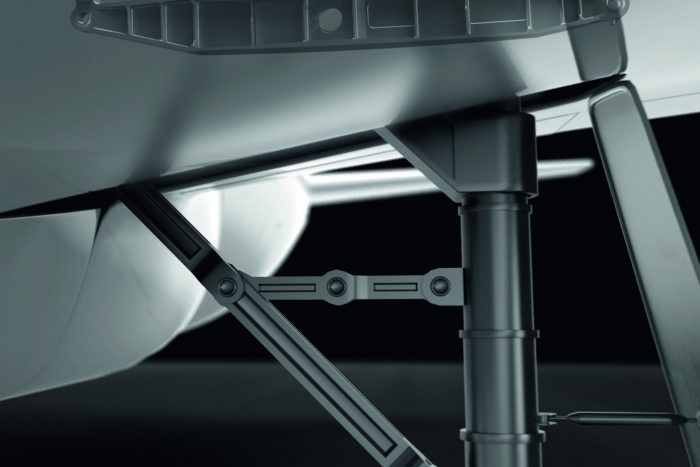

The landing gear mounts in modern aircraft are typical titanium structural components with large numbers of pockets.

The growing demand for titanium parts in the aerospace industry is only getting bigger, as these parts seem to satisfy both the need for light-weight and strong components. In fact, the demand is expected to increase by 20% over the next five years!

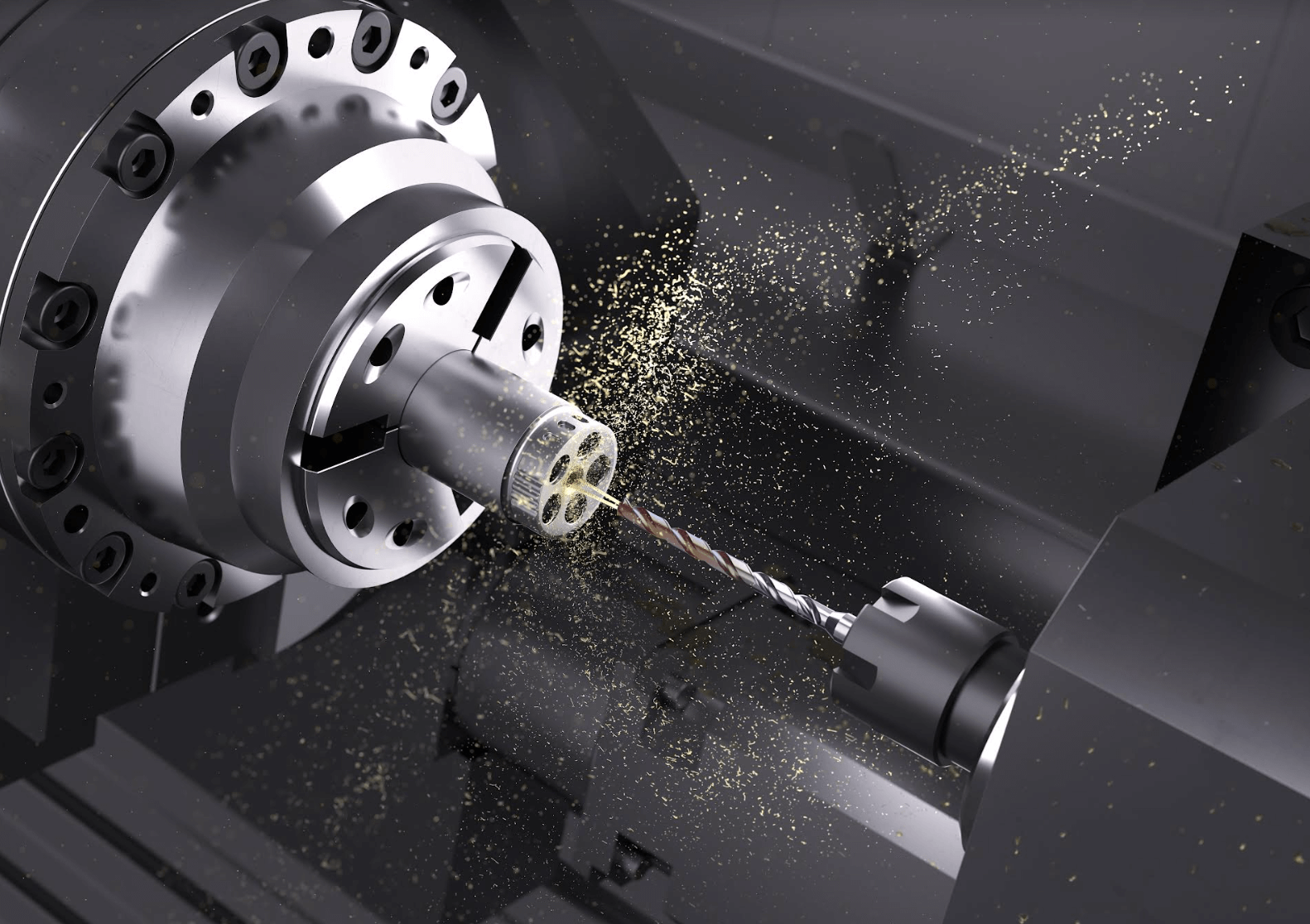

But, titanium presents a challenge when it comes to machining.

Many credit their machine tool with the capabilities when they cut titanium, but really, it comes down to two main factors… feeds & speeds and tooling.

Speeds and feeds are never simple. There’s always a need to use a recipe and then tweak for your specific machine. Even if the recipe is designed for your exact machine, speeds and feeds will still need to be adjusted due to subtle things like cutting environment, finish preference, and the type of tooling you’re using.

In the aerospace industry, titanium cutting is usually done from solid forgings and consists of pockets with thin walls and bottom faces, which can pose a challenge.

Using a generic component made from Ti6Al4V, the Walter demonstrated typical processes for structural components.

Dirk Masur, Component Manager Aerospace at Walter AG in Tübingen, Germany, together with his colleagues, works with titanium components and their special properties on a daily basis. “We focus on complete solutions,” he explains. “This means that we coordinate all aspects, such as the tool design, CAM program, and machining strategy in accordance with best practice considerations.”

The result is modern tool concepts which, in turn, are matched to the tasks in question, such as roughing, semi-finishing or finishing.

According to Masur, the development of productive and reliable strategies at Walter is based on knowledge of components which has been built up over a number of decades. “Our expertise is based on intensive partnerships with focus customers, universities and machine tool manufacturers. Together, we are continually developing the machining operations for key components. This is how we ensure that we are always using the very latest technology.”

In the end, the machining specialists from Tübingen provide their customers with customized processes which enable maximum machining volumes. The key here is to match the processes with the available machine type capacity. “The machining operations are simulated and verified before the handover,” Masur stresses, “this means that the user does not have any unpleasant surprises in terms of cost-effectiveness or process reliability.”

A good suite of tools from Walter for cutting commercially available titanium (Ti6Al4V, Ti 5-5-5-3, etc.), includes the M3255 tangential porcupine milling cutter, the M4002 high-feed face milling cutter (roughing operations), the Ti40 solid carbide end milling cutter, and the modular ConeFit variant with Ti50 changeable head (semi-finishing and finishing operations). Indexable inserts and solid carbide milling cutters help to maintain the balance in applications like this.

The new M2131 ramping milling cutter from Walter specializes in HSC machining of aluminium materials.

The coatings, as well as the macro geometry and micro geometry of the two solid carbide tools are designed specifically for titanium machining, which makes them perfect for aerospace applications. The M3255 and M4002 milling cutters have indexable inserts made from the new Walter WSM45X cutting tool material. The extremely tough CVD coating is ideally suited to high temperature alloys and stainless steel (ISO S and ISO M) applications, which includes titanium.

When looking at a material like titanium, using dynamic milling strategies is recommended. This improves both cost-efficiency and process reliability. With HDC, the machining conditions remain constant.

The constant engagement condition generates lower vibration – and thus results in better tool life and a lower tool wear rate. This also enables higher cutting lengths and machining volumes. At the same time, energy consumption at the spindle is reduced.

Using Walter tools and the proper cutting strategies (as well as feeds and speeds), making raw titanium into aerospace components is not only possible, but even fast and efficient.

Click here for more information.