Thinbit® 90° Mill A Groove®

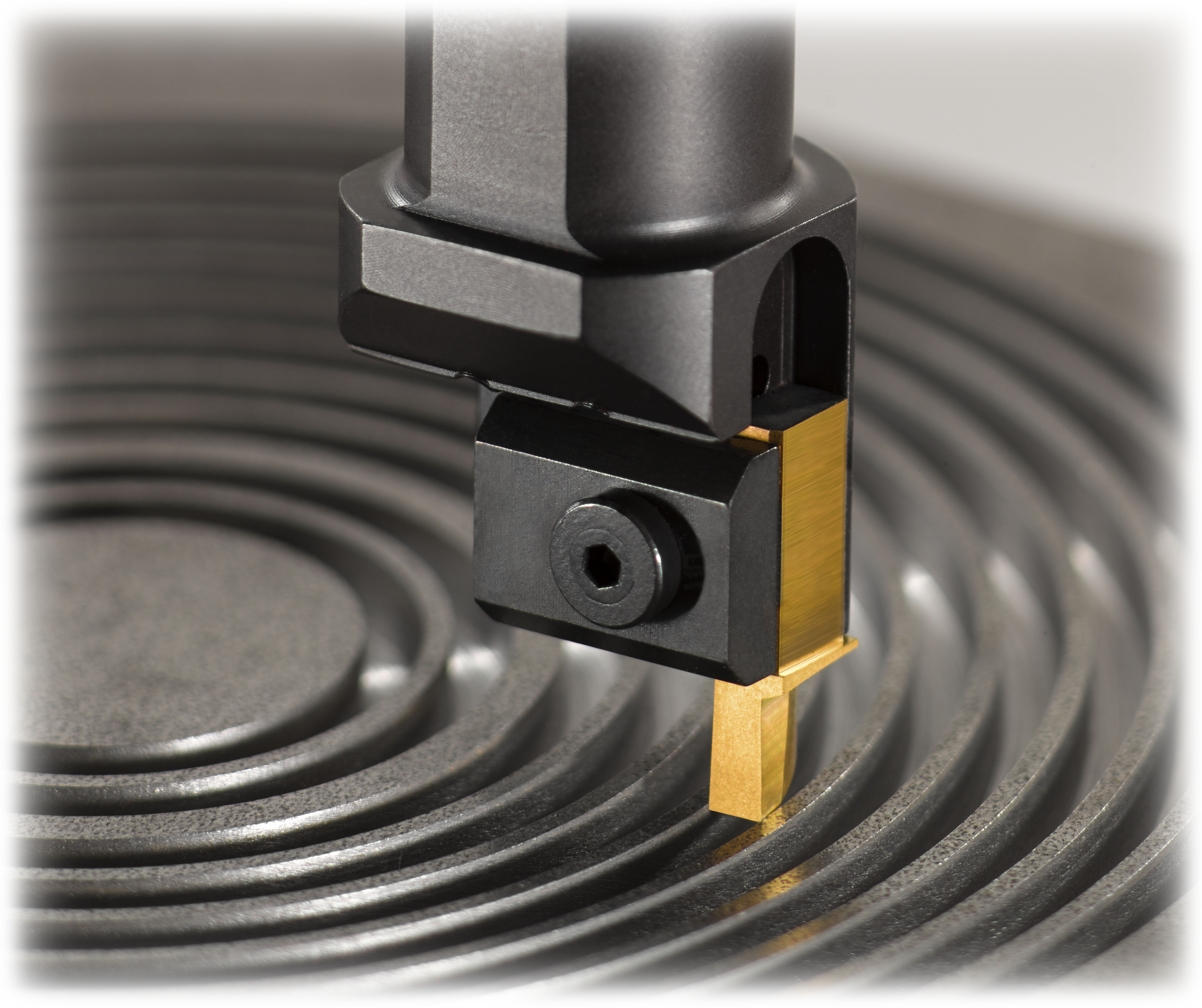

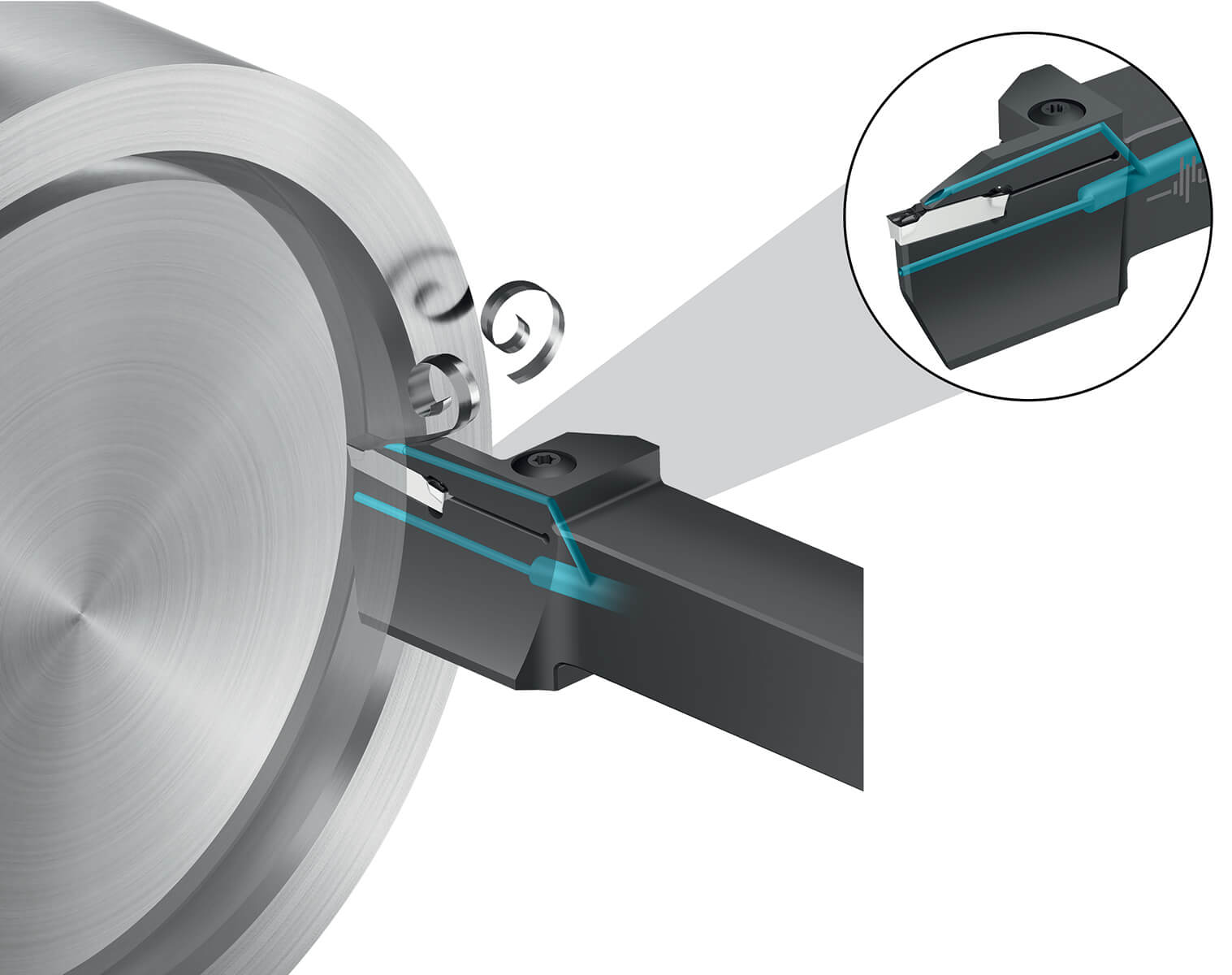

The MILL A GROOVE® line is a system designed to trepan on CNC and manual mills. MILL A GROOVE® will make your mill a more productive machine on your shop floor.

There are many advantages when using the MILL A GROOVE® system:

- Better sealing surfaces due to improved surface finish that is smoother and more consistent.

- Diameters that are concentric to the spindle rotation, not the table movement, resulting in greater circular accuracy.

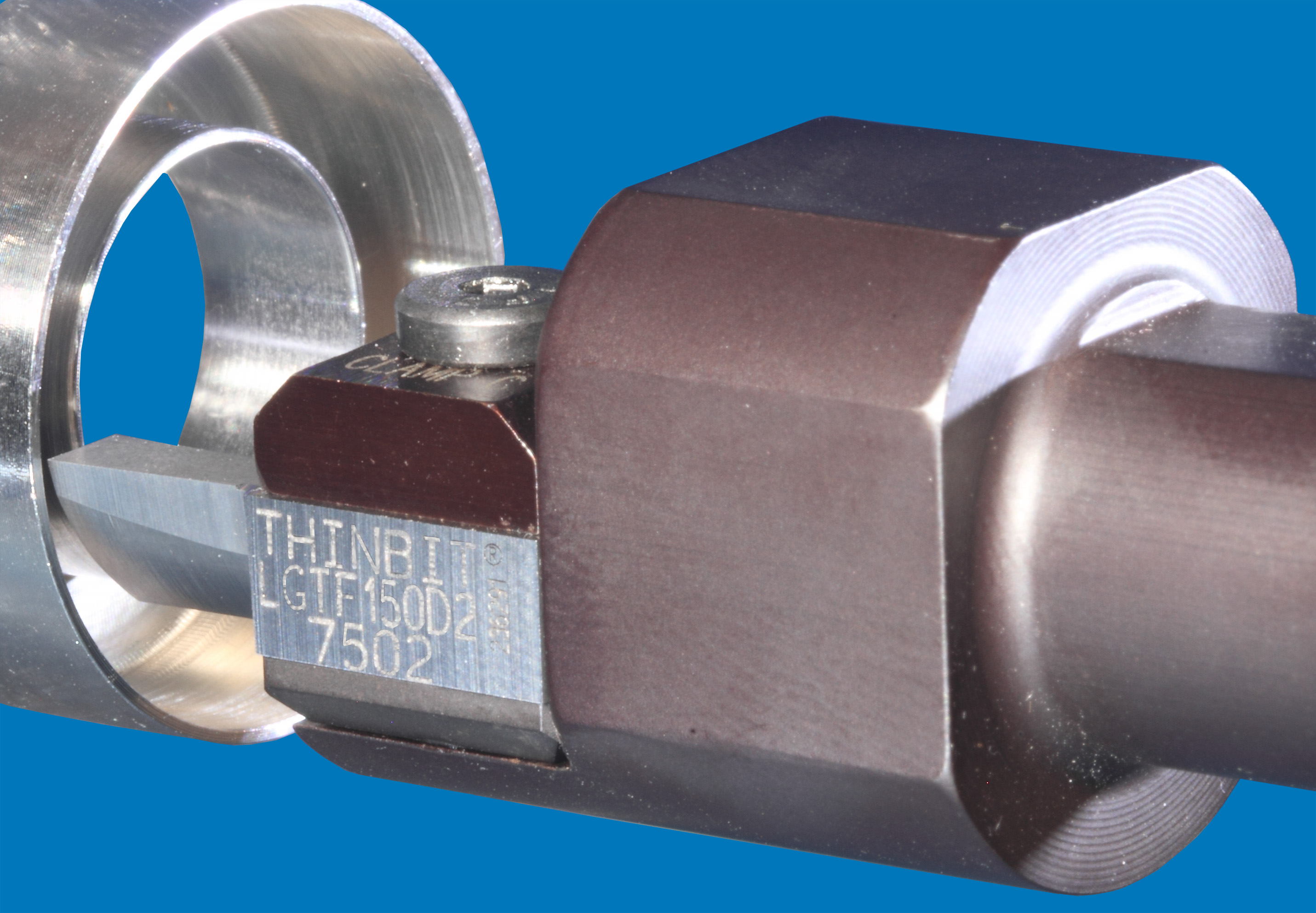

- Eliminates the use of a secondary lathe operation for face grooving.

- The cutting insert rotates about the spindle center, but does not rotate about its own center. The groove can be symmetrical, like a standard end mill, or asymmetrical. This very versatile tool can be used to cut step grooves, convex and concave radius grooves, chamfered edges, angles and special profiles with a single insert.

- When used as a single point face mill, the insert can be adjusted to control the exact size of the mill arcs to improve flatness, blending and cosmetic appearance.

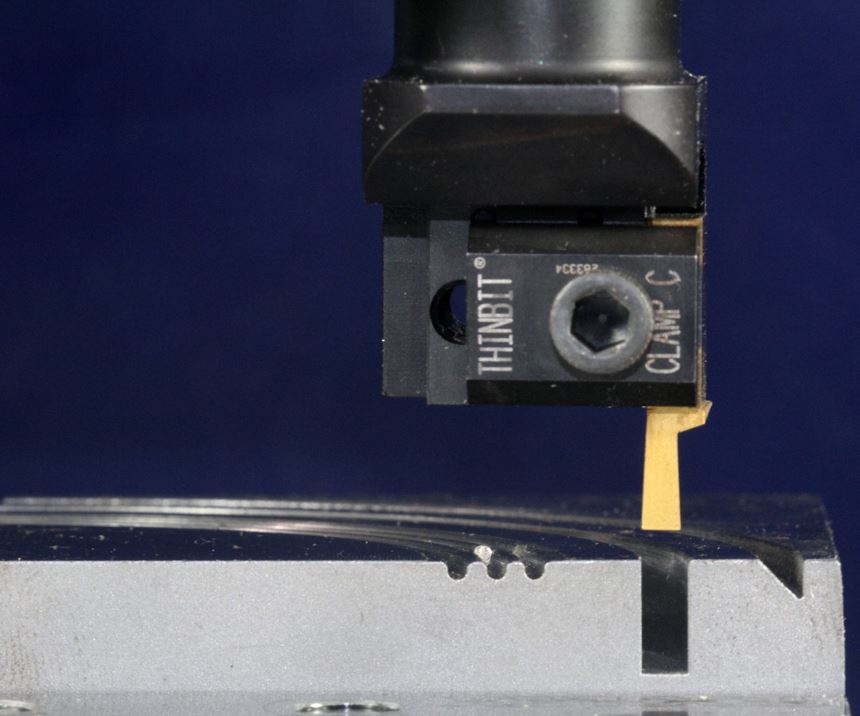

- Standard inserts in .001” increments, with sharp corner or any corner radius.

- Custom inserts can be made to match any groove form.

- Increased insert strength compared to an end mill of the same size due to greater cross-sectional area.

- Faster cycle times than interpolating a groove with an end mill

- You can get all of these benefits, and save money. The 90° MILL A GROOVE® offers a lower cost per groove.

Our testing has shown that when machining in 6061aluminum, the 90° MILL A GROOVE® system cut a groove .125” wide x .200” deep x 4.98”diameter in 18 seconds vs. 2.75 minutes with an 1/8” end mill. This is a cycle time reduction of 90%.

The 90° MILL A GROOVE® toolholders are designed to work in combination with boring heads and are available in common sizes with straight and 90° orientations.

Inserts for the 90° MILL A GROOVE® system are available from .004” through .150” in .001” increments. Major diameters start at .300”. Inserts are available in sub-micron grain carbide grades for ferrous and non-ferrous materials and HSS for composites and plastics. Inserts can be coated with TiN, TiCN, TiAIN or diamond film coatings. We offer PCD and CBN tipping options for improved performance in hard or abrasive materials.

For more information on these tools, along with the entire THINBIT® line of cutting tools, please visit our website at www.thinbit.com