Things to Consider When Investing in Milling Machines

Milling technology has come a long way. Newest milling machines are faster than ever before, can machine complex parts and work with the tightest tolerances.

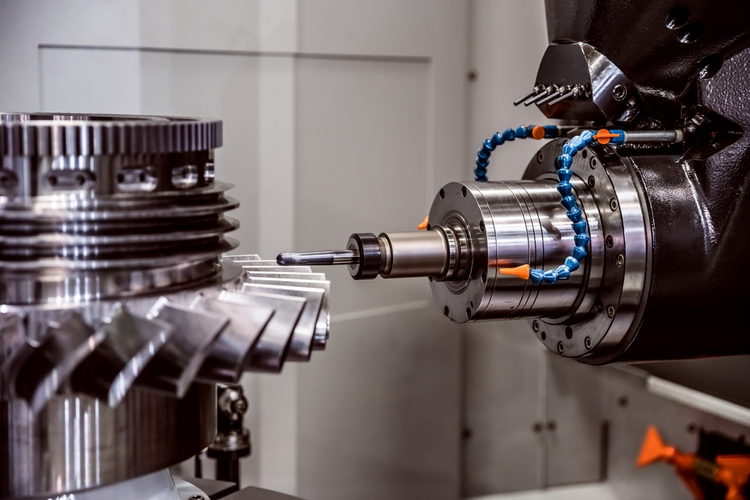

Image credit: canadianmetalworking.com

Machine shop owners, however, should take into consideration other aspects when deciding to invest in a state-of-the-art milling machine. Even the most advanced machine will deliver poor results if they are equipped with low-quality tools and fixtures.

External factors too play an important role when working with difficult-to-machine materials such as nickel-based alloys, titanium, and stainless steels.

So while the machine is one of the biggest factors in producing high-accuracy parts, many other factors come into play. And to leverage the milling center’s full power, metalworking companies must not underestimate the importance of the tooling, workholding equipment, and the software they use.

Here are the main factors to consider when considering investing in a new milling center:

Tooling

Advanced cutting tools have become fundamental in the modern metalworking industry. Tooling companies are constantly working to improve the capabilities of cutting tools to meet the demand for high-accuracy milling demands.

These cutting tools then need to be optimized for the machining capabilities of the milling center, and that’s where toolholders come to play.

With indexable tooling, manufacturers are pushing to increase the rigidity of the pocket of the tool.

Modular toolholders are the solution to this issue. They ensure rigidity and stable machining thanks to the extended gauge length, allowing manufacturers to obtain a balanced cut at a higher RPM.

Workholding systems

With the push into high-accuracy, 5-axis machining, shops need to ensure their workpieces are securely fixtured.

Manufacturers need to consider several different factors when choosing the proper workholding system, such as the capability of the machine, the size of the machine table and the size of the workpiece.

“The biggest machine and best cutting tools won’t get you anywhere if you cannot hold the workpiece in the correct spot with repeatability,” said Tyler Mardaus, design engineer at Kurt Manufacturing. “To see those gains and investment in more advanced machines, you really have to have workholding that will keep that part clamped with minimal deflection to counteract the cutting forces.”

CAM Software

Multi-axis, high-speed machines won’t be able to manufacture complicated components without the aid or CAM software.

While traditional multi-axis toolpaths were designed for machines generally cutting with a ball endmill, the improvements in cutting tool technology are now allowing for new, complex geometries.

As machines become faster and tooling becomes more complex, software companies are constantly coming up with new techniques and motion.

State-of-art CAM software is now capable of constantly adjusting the toolpath to maximize the usage of the tool while maintaining high speed and accuracy.

Understanding how to maximize this powerful software can be hard and time-consuming, but using those efficiencies and capabilities can dramatically save time and boost job efficiency.