Top Dial Test Indicators of 2022

Each year we ask the Practical Machinist community, through the our social platforms, to share their favorite model of a specific tool. In 2022, when searching for the Practical Machinist community’s top dial indicator models were, there was an unexpected twist. The most mentioned models were in fact dial TEST indicators and not dial indicators. There were even community members claiming that there is no difference between dial indicators and dial test indicators. You can find all of this on the posts on Facebook and LinkedIn. So we pulled the top dial test indicators mentioned and plopped them here! Scroll down to check out the models that made 2022’s top dial test indicator list.

Dial indicators are simply a staple in the machinist tool box. If you are needing to measure for consistency purposes and not comparative purposes, a dial test indicator is the indicator for you. The applications of this popular measuring tool are broad, ranging from tramming your milling machine to measuring the roundness or runout of cylindrical parts.

This article will cover some of the dial test indicator basics such as tool anatomy, usage details and calibration tips, so you can deepen your knowledge on these gauges before checking out the hot dial test indicator models of 2022.

Dial test indicator vs dial indicator

Unlike dial indicators, dial test indicators (or DTI) have a lever-type arm. The angular motion of the lever allows the contact to ride easily over irregularities on part surfaces. Potential alignment errors are measured by how far the arm is pushed sideways. This capability is lacking in dial indicators, because the vertical-action plunger may resist responding to surface irregularities pushing “sideways” against the contact. You can learn more about the differences between DTIs and dial indicators in our article Choosing the Right Indicator.

Understand the precision measurement tool

Using a dial test indicator is not very complicated, but it requires a little bit of patience and practice. The first step, one that many skip, is to understand the anatomy of a dial test indicator, as those parts are referenced throughout the process of using the precision measuring tool.

Any given dial test indicator is comprised of nine main parts

- The dial face showcases the measurement reading and can be oriented in different directions to satisfy the operator’s position.

- The hand/pointer is located on the dial face articulating the given reading.

- The turn counter (not labelled in diagram below) is the smaller gauge seen on the dial face. The turn counter counts the rotations or turns of the needle.

- The indicator cap is found at the top of the face and secures the spindle in place.

- The bezel hugs the circumference of the dial face and rotates for tool calibration and resets.

- The bezel clamp can be found on the side of the face and locks the bezel in place.

- Limit markers are moveable and set parameters depending on the project’s requirements.

- The stem protrudes from the bottom of the face connecting the spindle to the face.

- The spindle is responsible for detecting any imperfections.

- The contact point sits at the very base of the tool and supports the contact that must be made between the indicator and the part being measured.

Time to put the precision measurement tool to use

First, press the contact point against the desired part’s surface. As you press the dial test indicator against that surface, lock the dial test indicator into place and watch the dial as you move the part. It is important to note that test indicators allow just for a single revolution of the pointer around the dial, and the tool only allows for clockwise rotation as opposed to a dial indicator which rotates both clockwise and counterclockwise.

Like any other gauge, dial test indicators need to be calibrated frequently because usage of the tool impacts the tool’s accuracy. Dial test indicators are precision measurement tools, so it’s imperative to keep them…precise. Check out our article Understanding Gauge Calibration for more information.

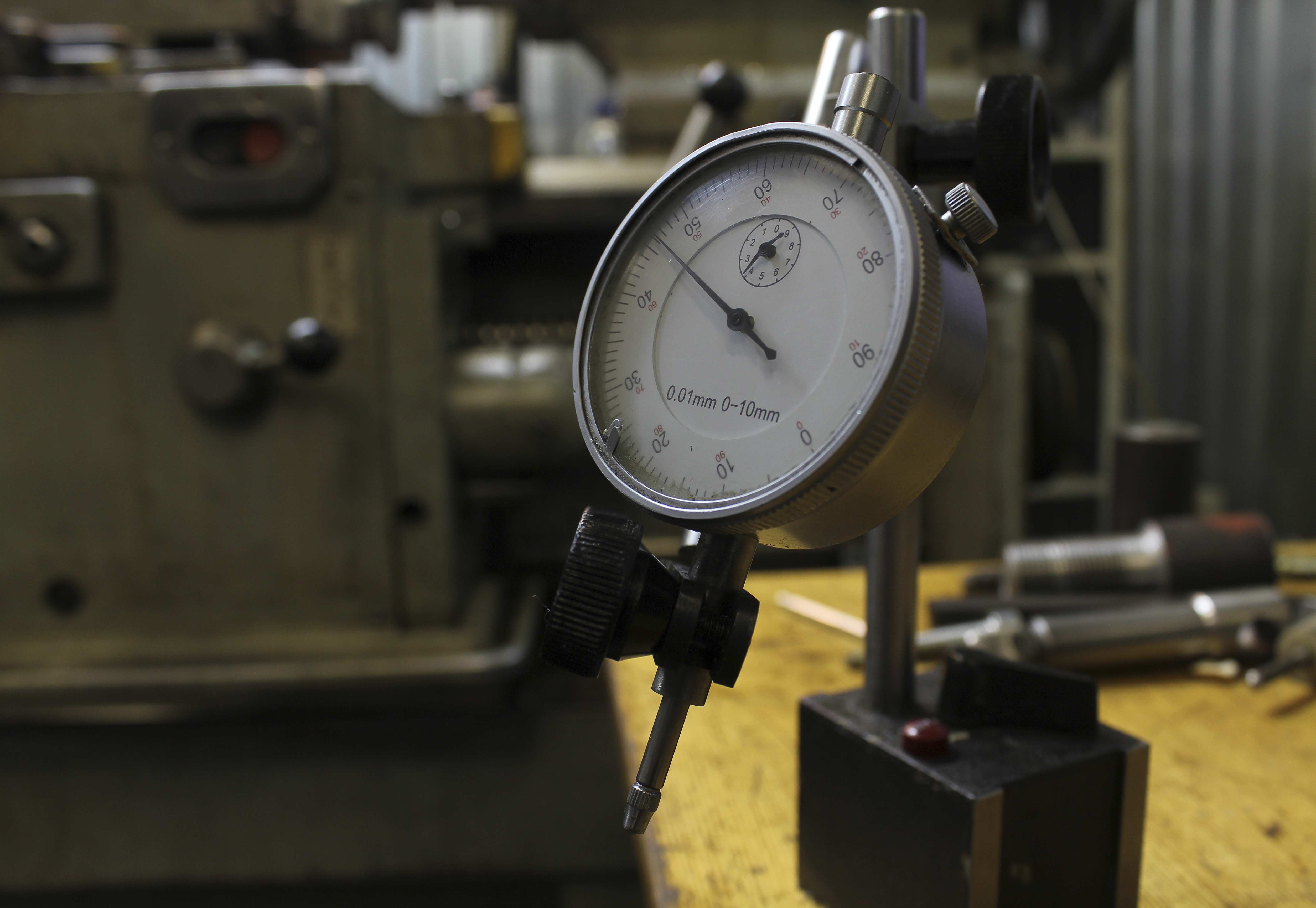

Indicator Base

Your indicator won’t be of much use without a base to hold it firm in place. An indicator base is an essential counterpart to the dial test indicator (and other dial indicators) because it holds the indicator in place to successfully achieve accurate readings. Want to know more? Check out our article Selecting a Magnetic Indicator Base and Arm.

Now onto the fun stuff, for a specific walk through of how to properly use the tool, see below.

To help you discover what model is best for you, we reached out to the Practical Machinist community via Practical Machinist’s social media platforms to learn more about the community’s preferred dial test indicators.

Let’s take a look at the top 5 dial test indicators models recommended by your fellow machinists.

Recommended Models

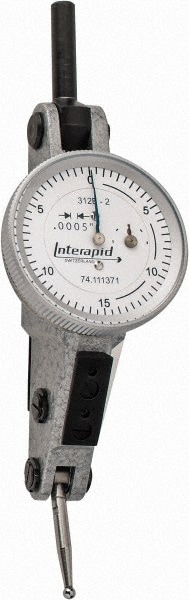

Interapid 0 to 0.016″, 0.000100″ Graduation, Horizontal Dial Test Indicator

Featuring an easy to read dial and jeweled mechanism fitted with ball bearings, this tool can achieve up to a maximum measurement of 0.0600.” This dial test indicator is just about as popular as the BestTest dial test indicator among the Practical Machinist community on social media.

Brown & Sharpe BesTest Horizontal Dial Test Indicator

This dial test indicator measures with +/-0.0001” accuracy making this dial test indicator both reliable and affordable. The Best Test model by Brown & Sharpe proved to be the most popular dial test indicator among the Practical Machinist community members.

Starrett 711HSAZ Last Word Dial Test Indicator

The Last Word by Starrett comes with a hard, chrome plated, steel ratchet contact point for taking measurements during machining, layout and inspection work. The face features half yellow shading for easy reading especially during when using a mirror or bore jig application. The indicator has a positive reversing switch for changing reading direction.

Mitutoyo 0 to 0.008″, 0.000100″ Graduation, Horizontal Dial Test Indicator

The face of this indicator has the stylus length marked should the stylus ever need to be replaced. This indicator features a unique sub-plate structure. This was done because the conventional approach to mounting the stylus pivot bearing screw in the frame was prone to loosen the more the indicator was used. The new sub plate structure eliminates this issue.

This post may contain affiliate links. Please read our disclosure for more info.

19 Comments

Interapid is expensive, but is high quality and accurate. Check your indicator accuracy with gage blocks. Also check or replace the contact point when worn. Keep clean and away from coolant.

Mitutoyo makes good tools too.

The Last Word indicators are rugged, but not as accurate. The replaceable contact point is a good feature.

Been in business repairing dial indicators for close to 40 years. The Interapid dial indicator is heads above the best. Quality, accuracy, integrity, design, etc.

how would you rank it compared to sylvac? i know we dont see much sylvac stuff in the states but i have a sylvac digital dial indicator that is good under a tenth on my gage blocks. was really impressed with the build quality of it blows my mitutoyos away and im generally pretty gay for japanese stuff. also am looking at getting a rebuild on at least one of my test indicators.

Do not forget the Compac by Tesa. Yes its expensive but is top of the line and worth every penny.

Keep in mind none of these recommendations relate to the ease of repair or calibration.

I’ve been told by the guys that fix indicators that B&S best test is #1 and (and this is going to hurt some feelings) #2 is interapid.

Fowler is at the bottom of the list just above the Chinese garbage. And the reason for that is design and parts.

Test indicators I have. Really good, flexible holders for them that lock securely into place on a variety of surfaces? That I DO NOT have. I’d love to see you do an article on test indicator mounting systems for a variety of purposes – focus on lathe and milling machine.

I make my living with a Inter rapid .0001 indicator. I have actually removed the face and taped off half the numbers and gave it a half yellow dial with a highlighter . It takes a while to dry , but it works great in set ups and swinging large diameters with a mirror.

Fowler?…don’t think so. The Starrett unfortunately is hard to read because of it’s small size. I believe Starrett is controlled as a Chinese company now. So don’t expect any changes. Interapid, Tesa and Mititoyo are high quality….for now.

The half yellow face on the Starrett Last Word is not meant to improve accuracy. It’s meant for the times you’re sweeping a hole and have to use a mirror to view the indicator. No question about which way it’s reading.

Thanks!!!! I have screwed that up countless times and wasted much time I’ll never get back. Plus now the last word will move up in the drawer next to the Mit.

I’m surprised Compac did not make it in the top 5 spot. I would definitely prefer one of those to the chinese made value line Brown & Sharpe or fowler.

Although the top 3 in my list are so close its hard to call. 1 Interapid, 2 Compac, 3 Swiss made Tesa/B&S. 4th would be the Mitutoyo and 5th would be the Starrett Last word.

I agree with all the previous comments, and having used and repaired all of these for over 45 years, the only indicators I would recommend are: B&S/Tesa, Interapid, Compac, and the older Alina.

Mitutoyo is ok, just never liked using or repairing them.

Any of the Chineese clones are unrepairable.

Last Word indicators are frustrating to use.

Going through my apprenticeship, the Starrett was nick-named “Last Chance”.

Also, MarTest makes a good indicator, and I have a Girod-Tast that I really like.

Mahr- Federal makes the MarTest.

In 35 Years in the tooling trade i have used a lot of different Indicators. My go to indicators are still My B&S and my Interapid Indicators. I had one Mitutoyo Top reader, after using for a month on the jig bore and being repaired 3 time for not reading right. I threw it against the wall and went out and bought a Interapid top reader. Not a big fan of Japanese Tooling. I got in the trade before Starrett and B/S went over to the dark side most of my tooling is starrett, just didn’t like their indicators.

The 15 buck Ching Chong “junk”dial test indicators will let you center a 4-jaw chuck every bit as fast and accurate as any $200 “Super” indicator will do. If you buy 2-of them and keep one for a spare in case you drop the first one into a punch press you will still have $170 in your pocket to buy beer after work with. . I have been through a grand total of 2 in the last 30 years. ,,,,

Some of them might feel like they are full of sand, but they still work just fine,,,,,But hey, It’s your nickle and if spending over 10 times as much to get the same job done gives to the king of the bragging rights title drive on! …

Bragging rights. Do Mercedes sell these things. Where can I buy? Sod the beer, I need status.

can i purchase a bezel cover for a best test dial indicator with one inch face and can i install it myself

(indicator stamped number B209300)

So – and kindly correct me if I’m wrong. Possibly my lack of experience/capabilities/relatively advanced age should give rise to some serious concern here – The evident (maybe there is an internal one ?) absence of a lever type sensor head on my Haimer & Renishaw Heads (AFAIK!) would really render such dial indicator types to be less precise when more accurate measurements are intended ? I find that somewhat difficult to believe.