Understanding Chamfer and Chamfer Mills

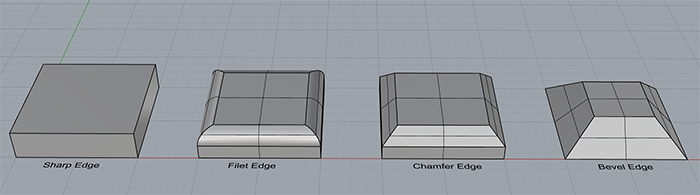

Experienced machinists often tend to confuse bevel and chamfer.

While oftentimes these two words can be used interchangeably, their definition do vary.

Understanding the difference between these two processes, however, is important as they lead to different workloads and involve different tools.

To break it down into simple terms:

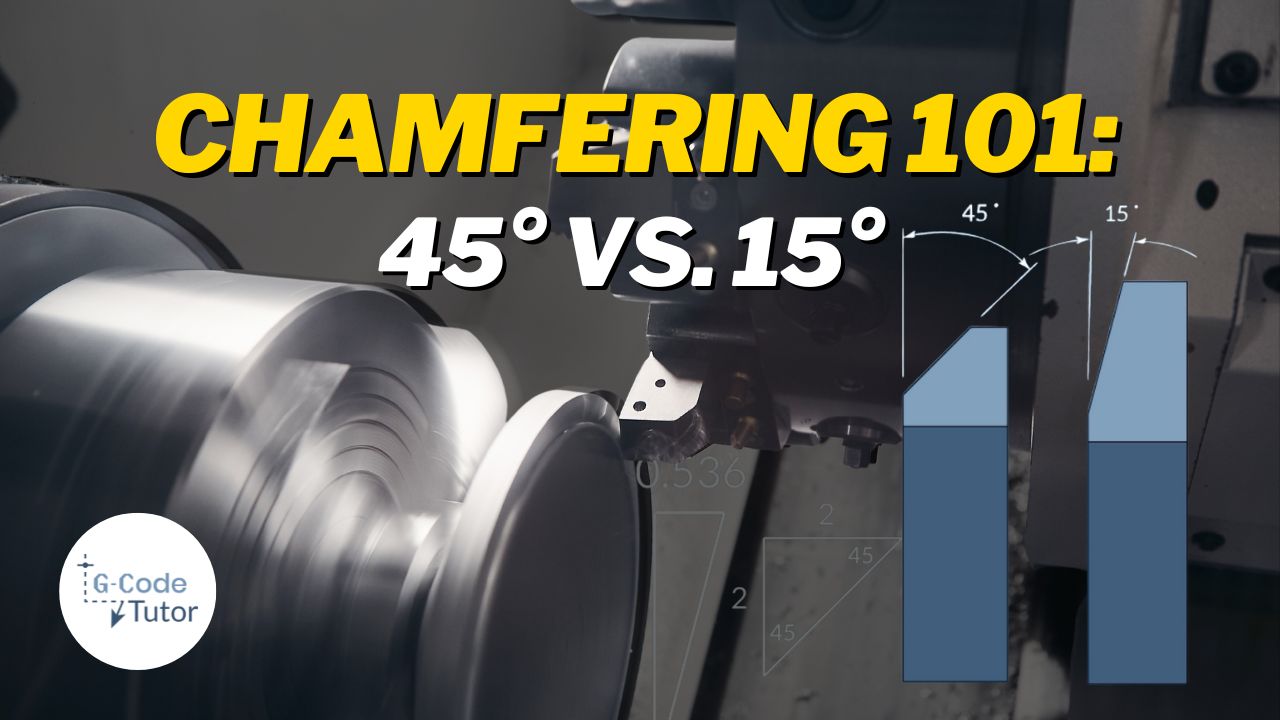

- A chamfer applies a flat at an angle to the edge. The angle is usually a 45-degree chamfer.

- A bevel occurs when the flat is the whole edge and there is no vertical wall.

Edges are often chamfered to reduce their sharpness or to remove burrs left behind by machining processes.

Also, if two pieces are to be welded together, a chamfer along the welded joint for both pieces is helpful to the welding process.

The cutting tools used to chamfer edges is the “Chamfer Mill”, but they can often be referred as “Chamfer End Mills”, “Chamfer Cutters”, “Chamfer Bits”, or “Chamfer Router Bits”.

Like most end mills, chamfer mills are available with indexable inserts. This feature provides advantages in terms of cost and flexibility.

Combination tools are also an option when machining chamfered holes. These tools can drill and chamfer at the same time, saving up time. Of course, it’s important to make sure that the hole depth requirements match the characteristics of the tool.

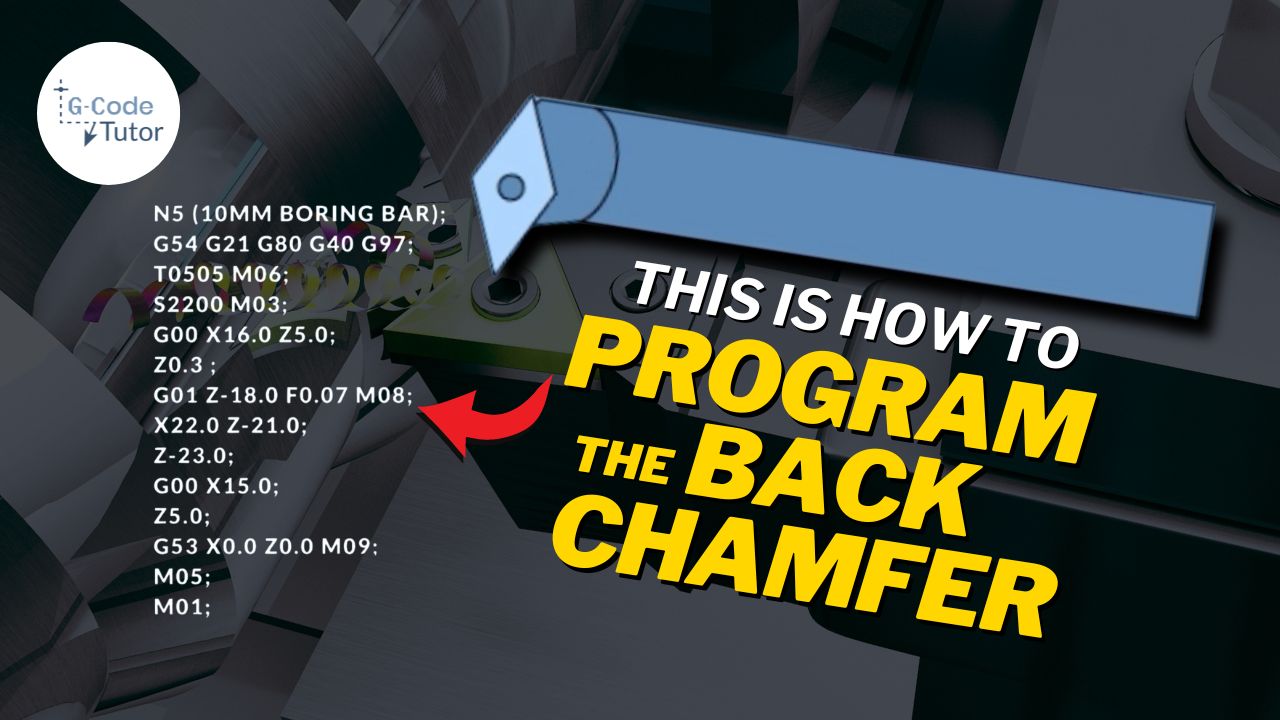

The process of putting a chamfer on an edge is also commonly executed on lathes. Since the operation is so common, many CNC Lathes have a built-in capability to do chamfering and corner rounding (filleting) of edges.