Walter Introduces The Groov∙tec™ GD G5011 Grooving Tool For Radial Grooving and Parting Off, Groove Turning and Copy Turning

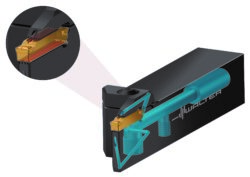

The Walter grooving system has a serrated seating profile on two sides of the insert for doubly secure clamping in the pocket.

Greer, SC— Walter has developed the Groov·tec™ GD G5011 grooving tool body that accepts patent-pending, double-edged GD26 cutting inserts with a double serration clamping profile for positively secure locking in the insert seat, increasing the stability and process reliability. The positive fit effectively absorbs lateral forces during longitudinal and copy turning. A raised center serration prevents incorrect installation.

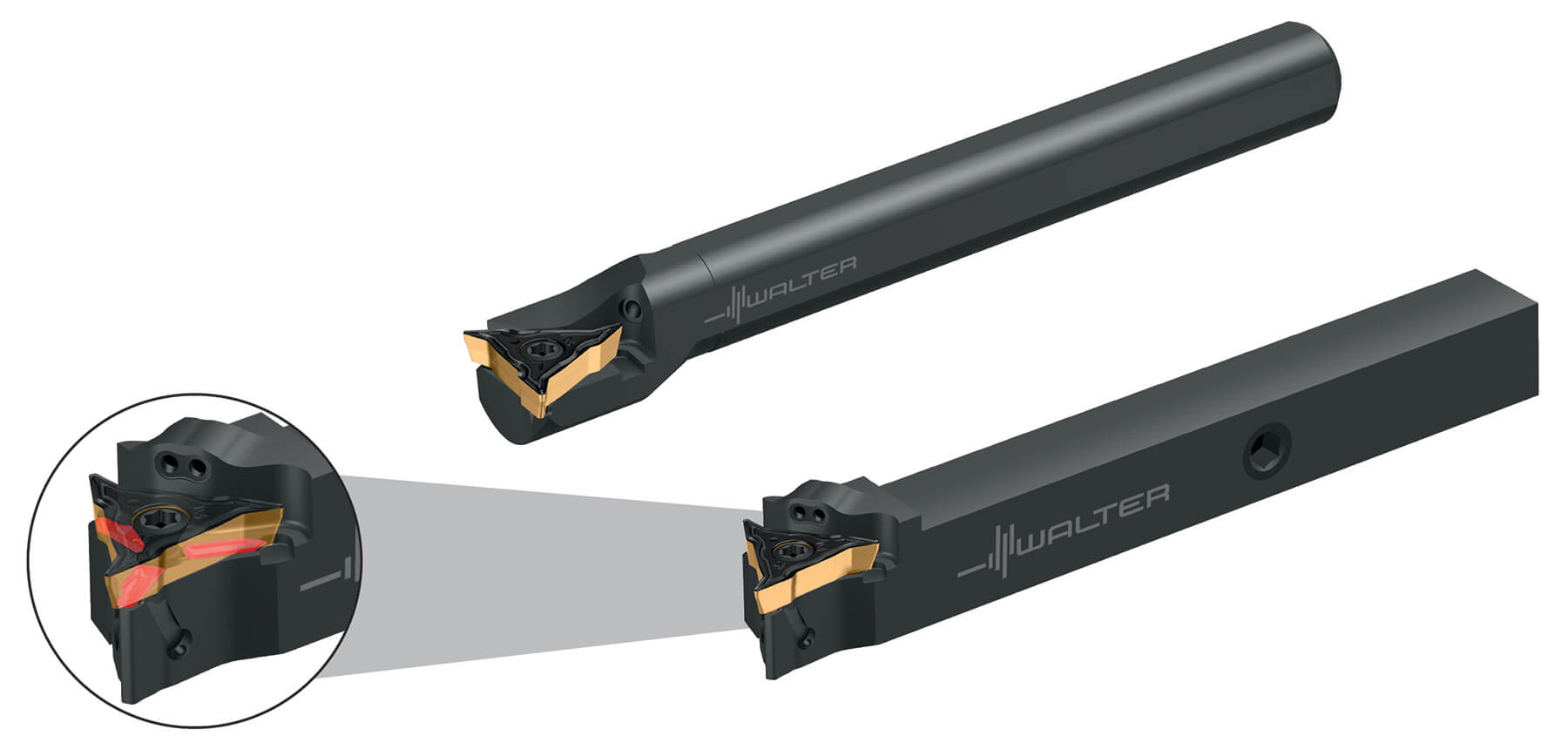

Compared to conventional systems with double serrations, the Groov·tec™ GD G5011 grooving system provides significantly more stability and process reliability. In addition to longitudinal and copy turning, the tool is suitable for a variety of applications, including radial grooving, recess turning (groove turning), offset grooving, chamfering, parting off with an inclined edge cutting insert and parting off with a straight cutting insert.

The geometries CE4, CF5, CF6, are for parting off and grooving, UA4, UD4 and UF4 for parting, grooving, and groove turning, and RD4 and RF8 for operations using the full radius.

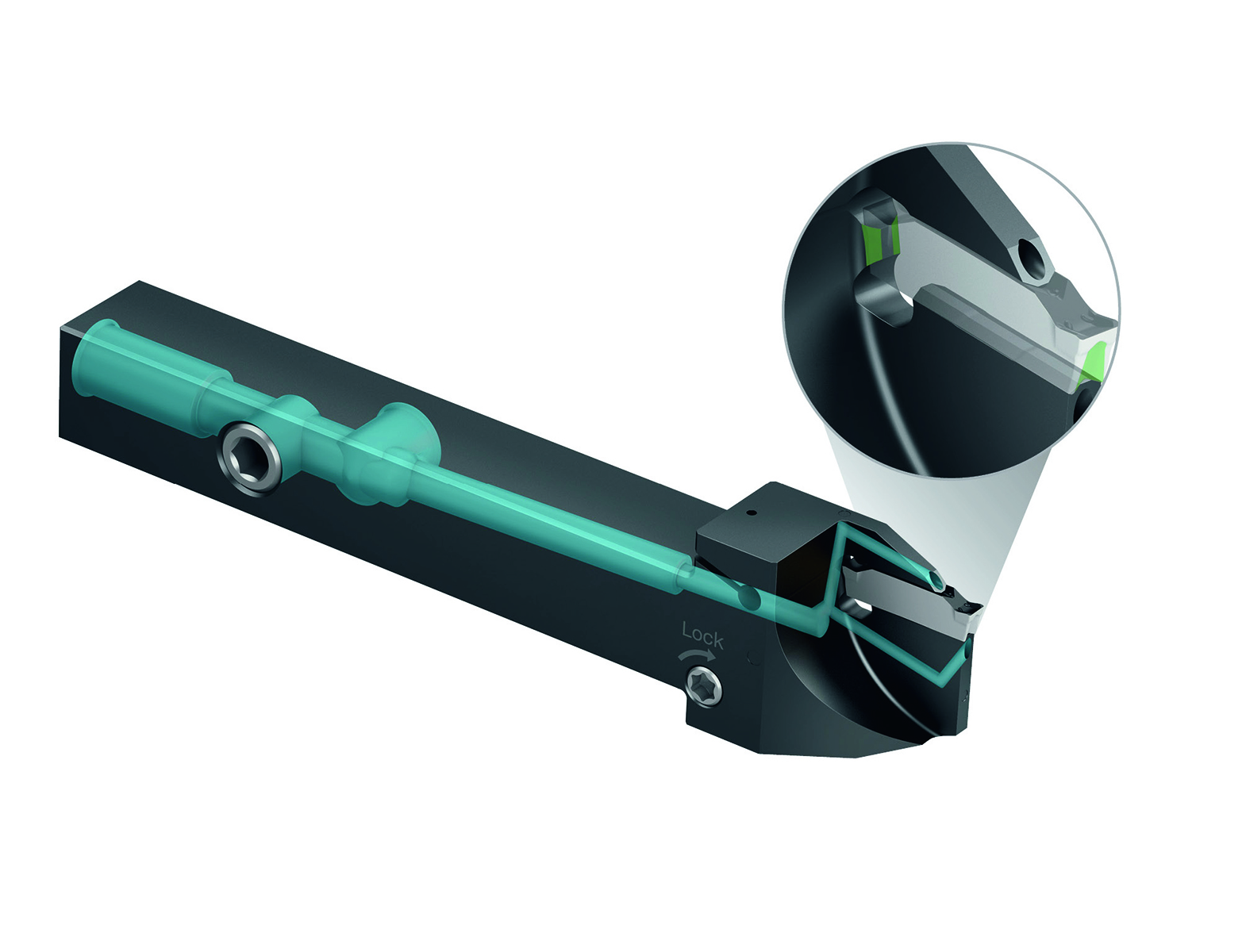

Inserts are available for grooving widths of 2.5, 3.0, 4.0, 5.0 and 6.0 mm. Indexable insert clamping can be operated from both sides. For optimum tool stability, there are two grooving depths of 12 and 21 mm. The corresponding toolholder shank sizes are 0.625 in., 0.750 in. and 1 in. as well as 16×16 mm, 20×20 mm and 25×25 mm.

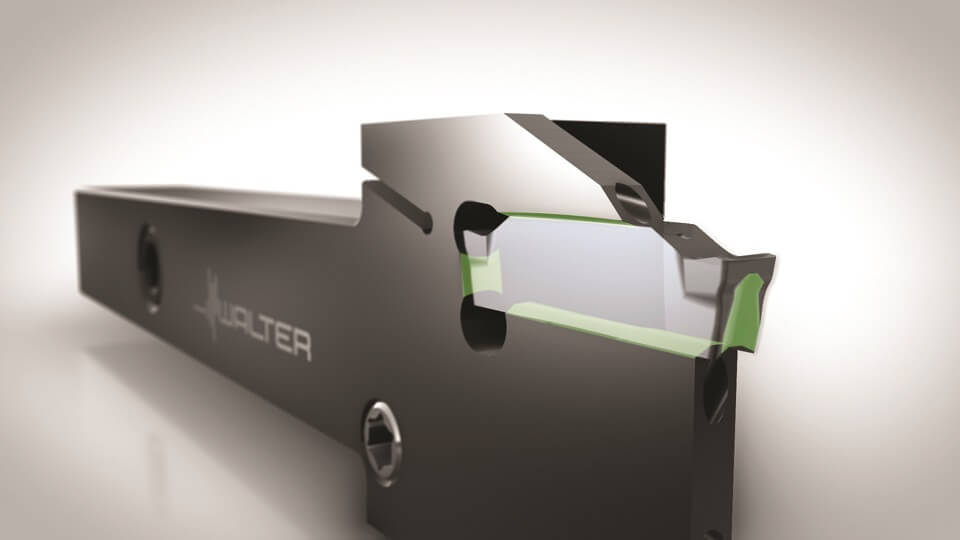

The new serration profile and precise coolant delivery to the tool/workpiece interface enables increased cutting parameters, and the tool can be used with or without cooling. Precision cooling on the rake and clearance surfaces is provided at a pressure up to 2,176 psi (150 bar) ensuring significantly higher tool life and reliable chip evacuation.

Thanks to the wear-resistant Tiger·tec® Gold grades, end users can maximize productivity and service life. Four PVD grades are available for machining steel, stainless steel and super alloy materials: WSM13G, WSM23G, WSM33G and WSM43G. In addition, three CVD grades are available for machining steel and cast iron: WKP13G, WKP23G and WKP33G.

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general metalworking industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Greer, SC, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazil. www.walter-tools.com/us.