Welcome to Swiss-Lathe Machining on a Desktop

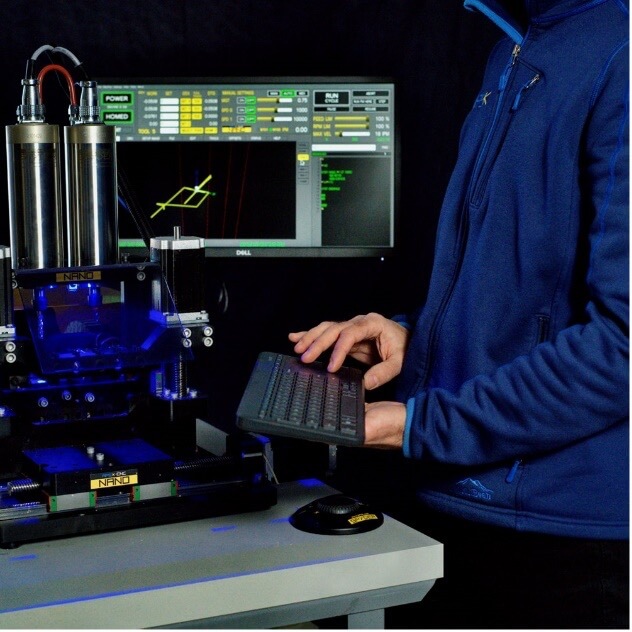

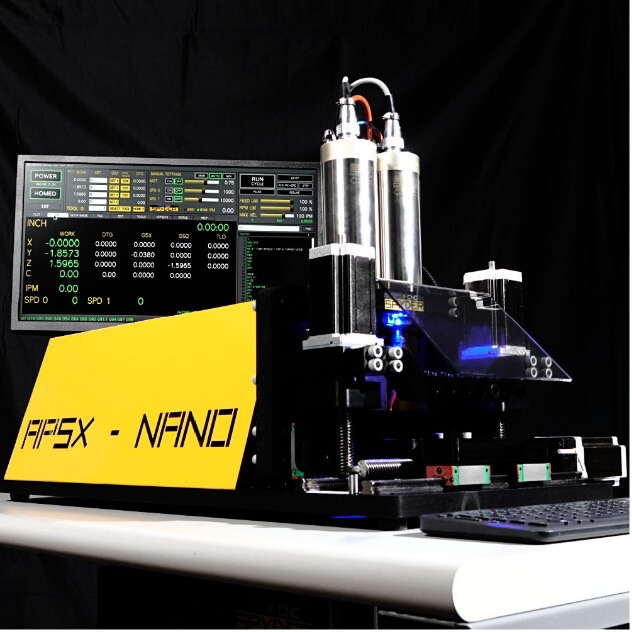

APSX-NANO CNC Swiss Lathe can machine ALUMINUM, STAINLESS STEEL, TITANIUM (Grade 2), BRONZE, BRASS, DELRIN (ACETAL), and other material with high precision on a desktop. It is a complete, ready-to-run system that includes the stand, embedded PC, keyboard, monitor, pendant, and a mist system and uses just a standard wall outlet for power.

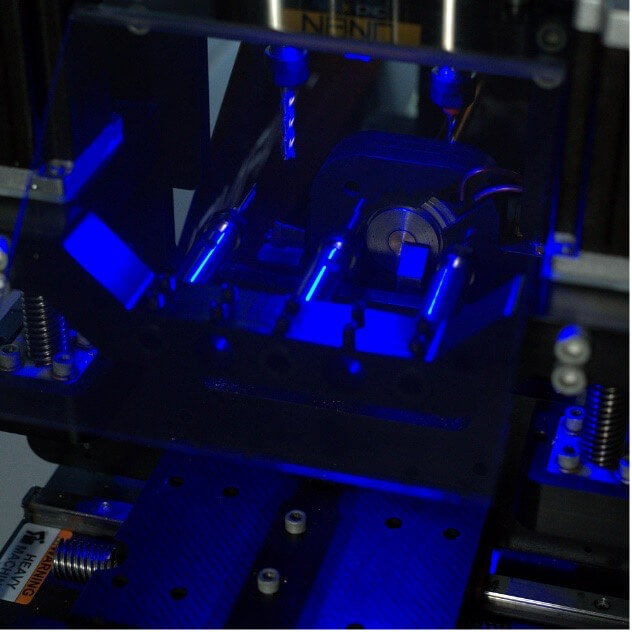

The key to Swiss-style CNC turning is adding a bar feeder that spins the round bar and slides through the guide bushing in the Z-axis direction. The APSX-NANO has a max capacity of 20 inches long bar stock at a time.

It is best when parts have milled and turned features. CNC Swiss machining allows for many milled features (flats, hex edges, slots, rotary broaching, rigid tapping, thread milling, etc.) to be produced during the turning process without the need for multiple setups on additional equipment, providing greater production efficiencies with one process.

WHICH Industries?

- Aerospace, automotive, drones, firearms (small arms and ammunition), and electronics components with multiple applications.

- Medical and orthopedics: Bone screws, anterior cervical plates, fracture components, bone drills, surgical taps, orthopedic devices, surgical instruments, bone shavers, and more.

- Dental: Titanium implants, dental taps and drills, abutments and locking screws, dental driver instruments, orthodontic components and more.

- Minimally invasive surgery: Screws, plates, housings, distal tips, cones, connecting rods, pins, grippers, surgical drivers and more.

- Military vehicles and aviation: Cargo handling systems, guided missile, fuel systems, cockpit instrumentation, seatbelt mechanisms, cabin pressure control, wing flap actuation, antenna control, drones and more.

APSX-NANO – SPECIFICATIONS

- 31″ (D) by 14″ (W) machine base footprint

- Standard bar diameter is 0.50 inches

- Max bar diameter is 0.75 inches (Optional 0.75″ and 0.25″guide bushings are sold separately)

- Max bar length to install: 20” (Machinable length: 17”)

- Main servo motor (Teknic) spindle RPM is 1800 and power is 300W – 0.43 degrees resolution and 0.03 degrees repeatability

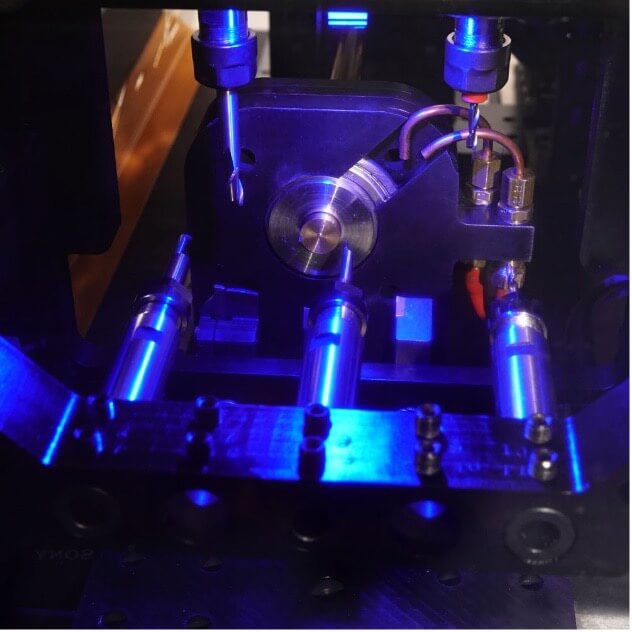

- Number of external (OD) tools: 6 (12mm X 12mm profile)

- Number of internal (ID) tools with ER11 collets: 5

- 2000 – 20000 RPM Pressured Air-Chilled 500W Live Tool Spindles (2) with ER11 collets – 80PSI shop air with 0.25″ female coupler required

- Three NEMA23 stepper motors with a rapid speed of 90 IPM on X, Y and Z axes

- Stepper repeat accuracy at no load (+/- 0.0002″) and achievable machining accuracy (less than 0.0005″) or better

- 120V standard wall outlet with proper grounding

- Adjustable mist (coolant) on the point of machining

- APSX CNC software is installed (easy to read user interface)

Visit the APSX-NANO product page here: https://apsx.com/apsx-nano-cnc-swiss-lathe

APSX LLC

11121 Kenwood Rd.

Blue Ash, OH 45242 USA

1-513-716-5992

Instagram: https://www.instagram.com/apsxllc/

YouTube: https://www.youtube.com/channel/UCoeQLNGN6K0Y6a2ccljxWuw