What Tool Should You Use When Turning?

Every machinist has asked this question at some point: “What insert should I use for turning?” Whether you’re roughing, finishing, or need a special profiling tool, using the right insert can make or break your machining process.

Luke from Crusader Machine breaks it down in plain English—no overcomplicated nonsense, just real talk on picking the right tool for the job:

✅ Rough Turning – Best inserts, feed rates, and depth of cut

✅ Finish Turning – Proper allowances and surface finish tips

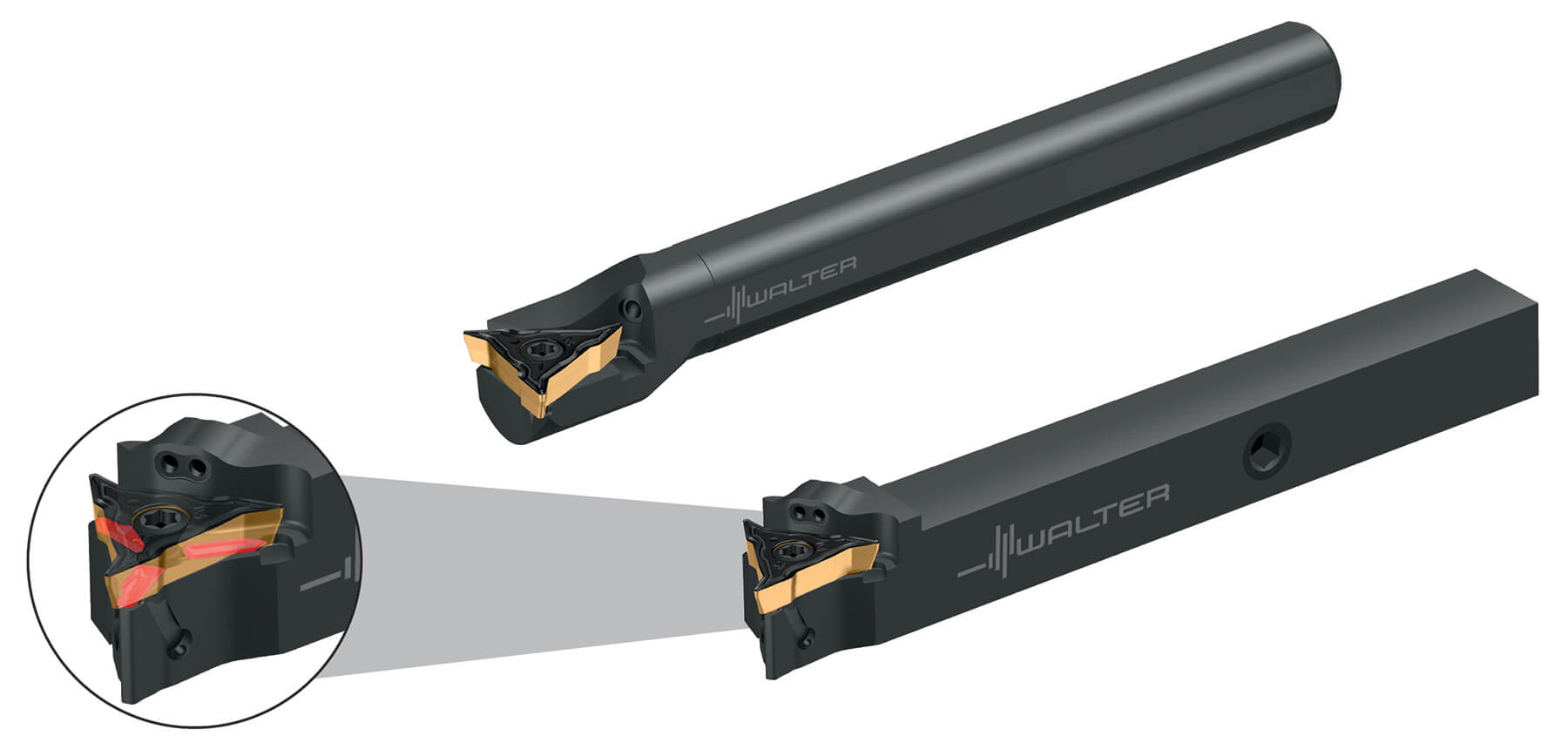

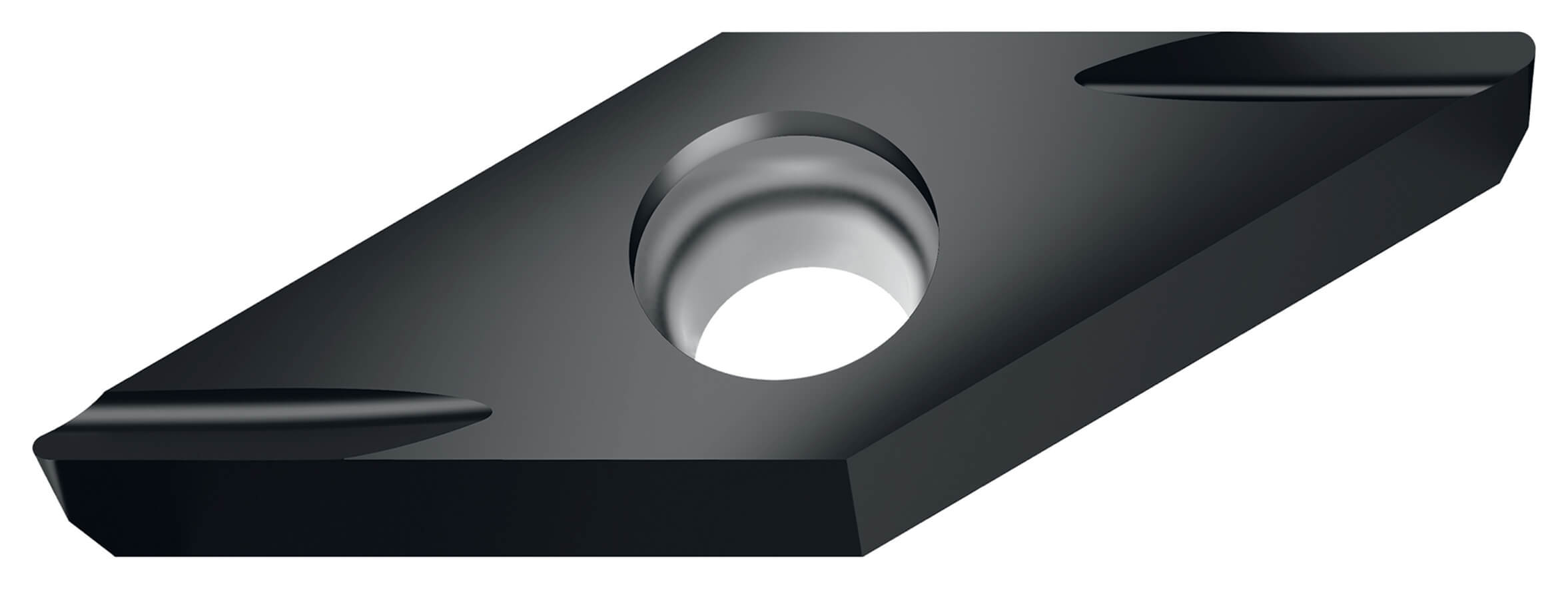

✅ Special Inserts – When WNMG, VCMT, or BMG inserts work best

✅ Speeds & Feeds – Simple rules to dial in your cutting parameters

Rough Turning Rule of Thumb:

✔️ Feed Rate: 1/3 to 2/3 of the nose radius

✔️ Depth of Cut: At least 1x the nose radius

✔️ Check Surface Footage from Manufacturer

For Brass?

One tool can rough & finish—no need for extra tooling!