Who is Afraid of True Position?

Some folks are freaked out when they find GD&T symbols on a drawing, especially true position. However, you should be delighted when you see it since it often allows for a “Bonus Tolerance” that actually makes your life easier.

What is True Position?

True position is a drawing symbol (⌖) that defines the permissible variation of a feature’s location from its “ideal” position. It is part of GD&T (Geometric Dimensioning and Tolerancing), which is a set of rules and symbols used on a drawing to communicate the design intent.

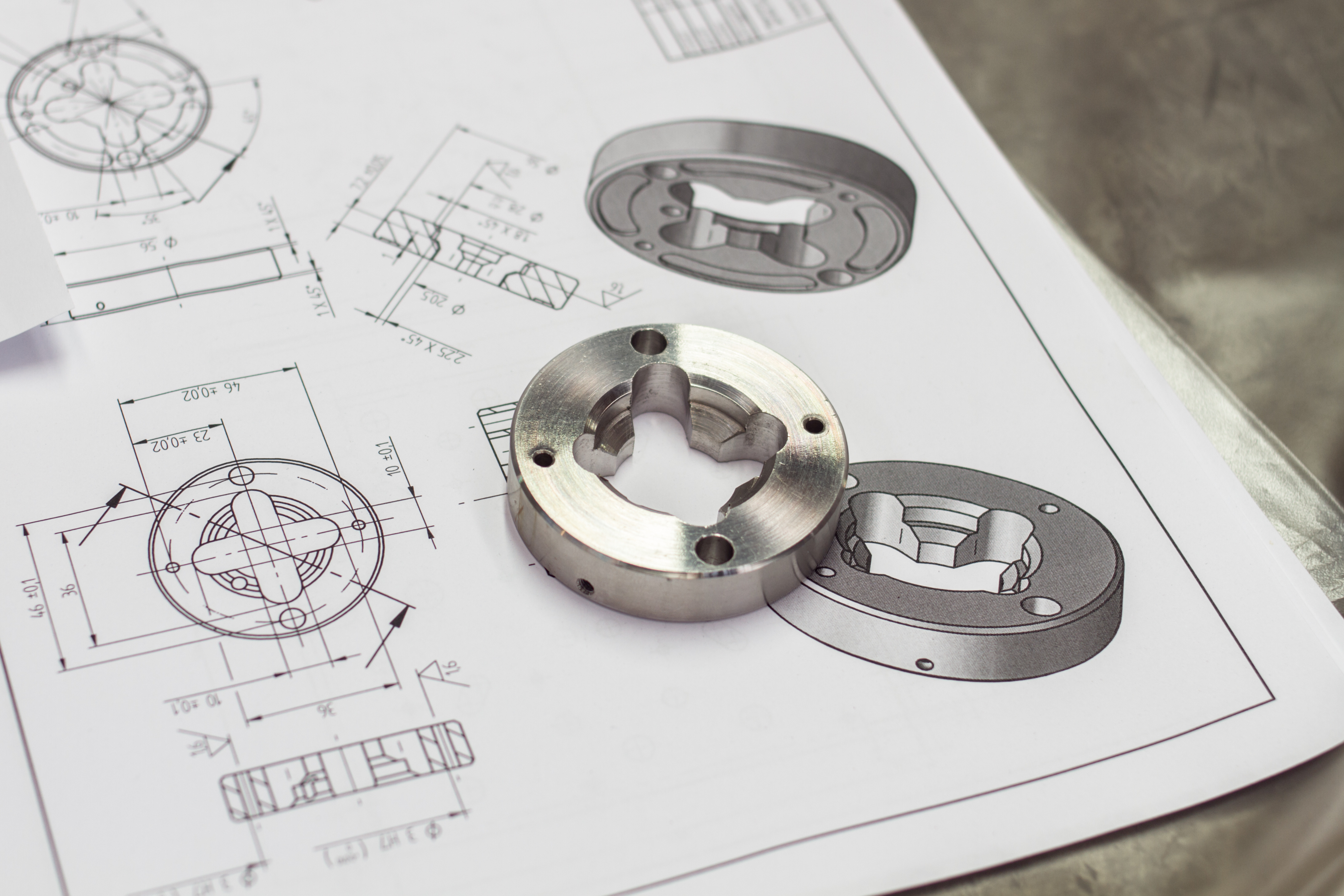

How is True Position Marked on Drawings?

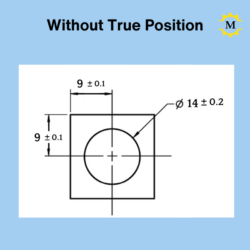

In drawing #1, we can see the “classic” dimensioning specifying the positions of a bore. The tolerance on the position of the bore is controlled for each axis separately and does not depend on the bore’s diameter.

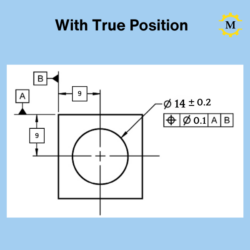

Drawing #2, shows the same part with the use of the true positions symbol.

- The position is denoted inside a box and without a tolerance.

- The position must always refer to a datum (▲), usually a plane or a cylinder.

- The tolerance on the position (in our case 0.1) defines the permissible distance of a feature’s location from its “ideal” position.

True Position Notation

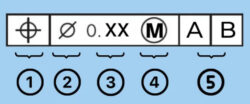

- True Position symbol: It means that all the preceding symbols and numbers correspond to a true position tolerance.

- Diameter Symbol: If present, it indicates that the feature and tolerance are diametrical. True position is most often used on holes and, therefore, will include the diameter symbol. In such a case, the position deviation is multiplied by two. (see formula). If the feature is a slot, then this symbol will be omitted.

- Position Tolerance: The maximum allowed deviation from the theoretical position.

- Material condition: If a material condition is indicated, you can add a Bonus tolerance to the allowed deviation (3). (True position is typically paired with MMC)

- M – MMC – Maximum Material Condition.

- L – LMC – Least Material Condition.

- Omitted – No material condition.

- Datum: The datum planes (or axes) from which the position is measured.

True Position with MMC (Maximum Material Condition).

Maximum Material Condition (MMC) is a GD&T modifier marked by a circled M (Ⓜ). If added to the callout, It indicates that the position tolerance should be considered when the bore/pin has the maximum amount of material.

- In a hole/bore, MMC = Minimum allowed diameter according to the tolerance.

- In a Shaft/pin, MMC = Maximum allowed diameter according to the tolerance.

Combining true position with MMC is very powerful. It means that the maximum allowed position deviation (3) is considered where the feature’s size is at its maximum material condition. As the difference between the feature’s measured size and its MMC grows, the tolerance on the position grows. This additional tolerance range is called Bonus Tolerance.

Bonus tolerance (BT) increases the allowed position deviation (3) due to the feature’s size relative to its maximum material condition. The minimum bonus tolerance is zero, and the maximum is the tolerance field.

True Position Calculation

If these calculations are giving you a headache, you can visit the Online True Position Calculator, which will do all the hard work for you!

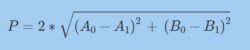

- TP – True Position. Maximum allowed positional deviation (0.1 in our case).

- A0, B0 – Theoretical required feature’s position (9 for both in our case).

- A1, B1 – Measured position.

- P – Position deviation from the nominal.

- D0 – Nominal diameter of the feature (14 in our case).

- T – Features tolerance (0.2 in our case).

If P<=TP, the feature is within the permissible position envelope. If P>TP, Then the position is non-conforming.

Usually, ture position is paired with MMC (Maximum material condition). In such a case, the calculation should proceed as follows:

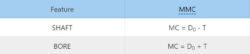

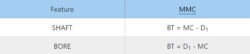

- Obtain the Material Condition (MC) according to the formula in table #1 (depending on your feature type).

- Obtain the Bonus Tolerance (BT) according to the formula in table #2.

- Calculate the final True Position TP=TP+BT

If P<=TP, the feature is within the permissible position envelope. If P>TP, Then the position is non-conforming.