WTO at IMTS 2024 – Booth #431464 West Building

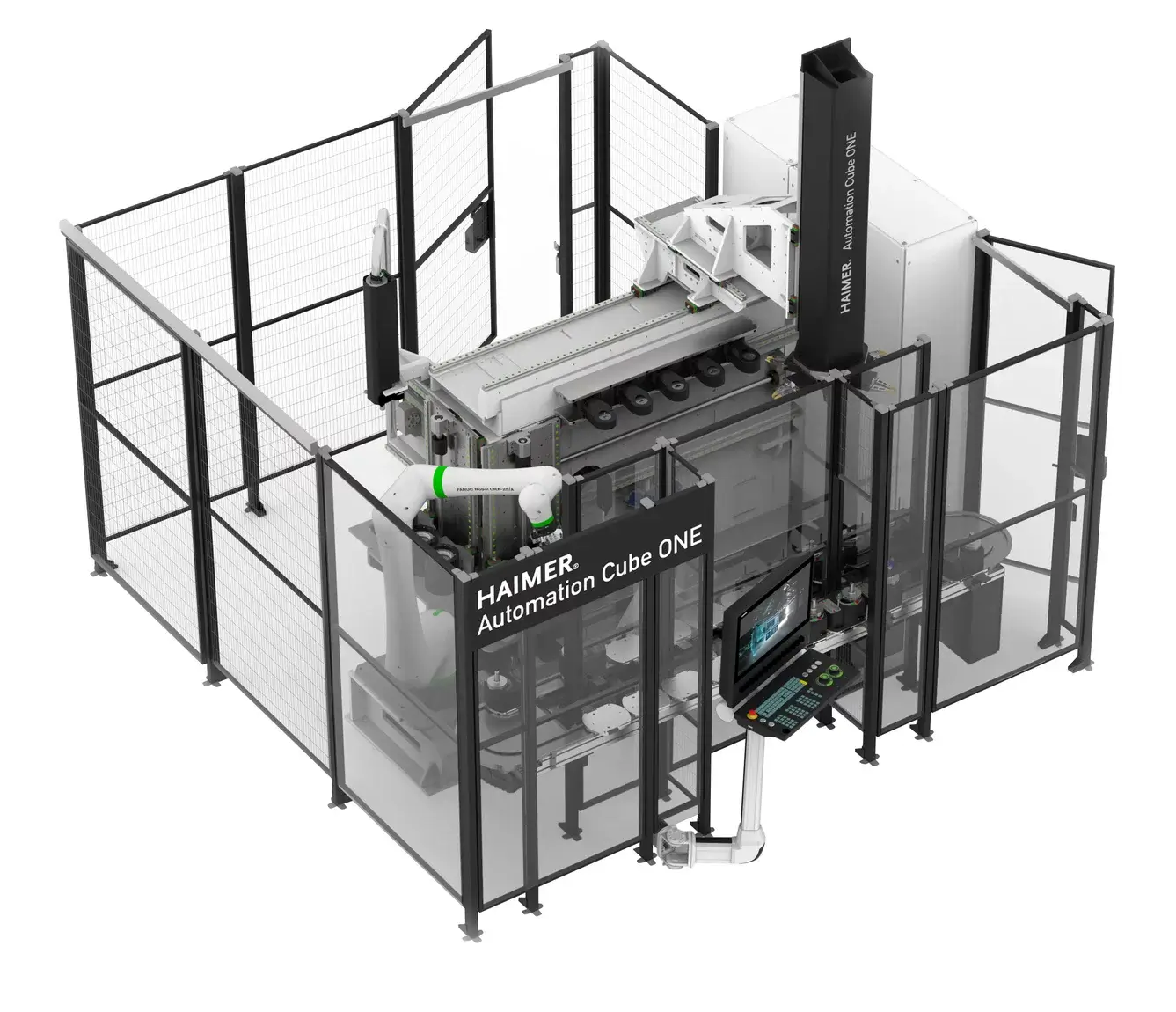

IMTS 2024: High process reliability in full automated turn-mill center cells by using innovative “smart” technology from WTO – Booth #431464 West Building

Increase the process reliability and productivity of turning centers in automated manufacturing cells by using intelligent driven tool holders and the innovative „smart“ technology from WTO for online process monitoring.

Find out more about the new „smart“ technology and other innovative tool holder solutions from WTO to increase the productivity and flexibility of turning centers at our booth #431464, West Building at the IMTS!

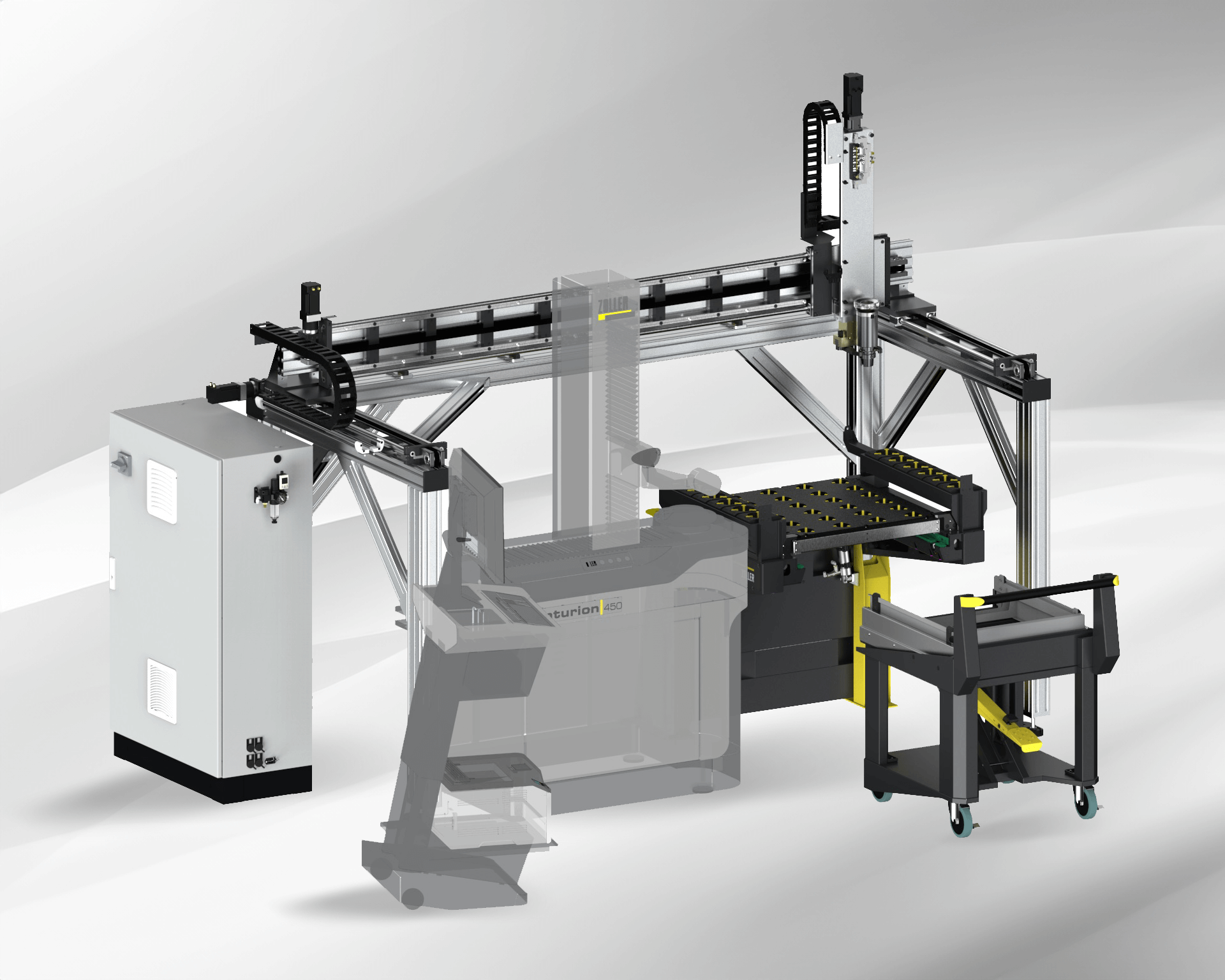

QuickFlex® smart

The new generation of Smart Driven Tool Holders QuickFlex® smart with intelligent online process monitoring for high process reliability in fully automated turn-mill center cells.

IMTS PREMIERE:

WTO “myTools” App for the digital access to all information (manual, drawing, etc.) via DataMatrix code on the tool holder.

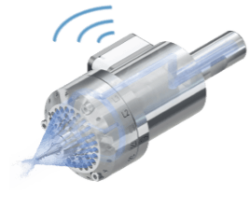

CoolSpeed® MAX

Coolant driven Ultra-High-Speed Spindle up to 60,000 rpm with two turbines and adjustable number of jets to regulate the coolant flow rate.

Efficient and process-safe with wireless spindle speed monitoring.

Broaching Unit

High productive machining of ID and OD gears and splines.

IMTS PREMIERE:

Now also available with shorter (26 mm) and longer (52 mm) working stroke.

Power Skiving Unit

High productive machining of ID and OD gears and splines.

IMTS PREMIERE:

Extended product range available to match machine sizes.

QuickFlex®

Unique quick-change system for turning centers.

IMTS PREMIERE:

New QuickFlex® adapters with Hydro Chuck clamping and Mini Floating Chuck adapters with internal coolant (IC).

nanoFlex®

The new universal quick-change System for Swiss Type turning centers with the capability to directly clamp ER collets.